Method for sensing amount of clothes in washing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

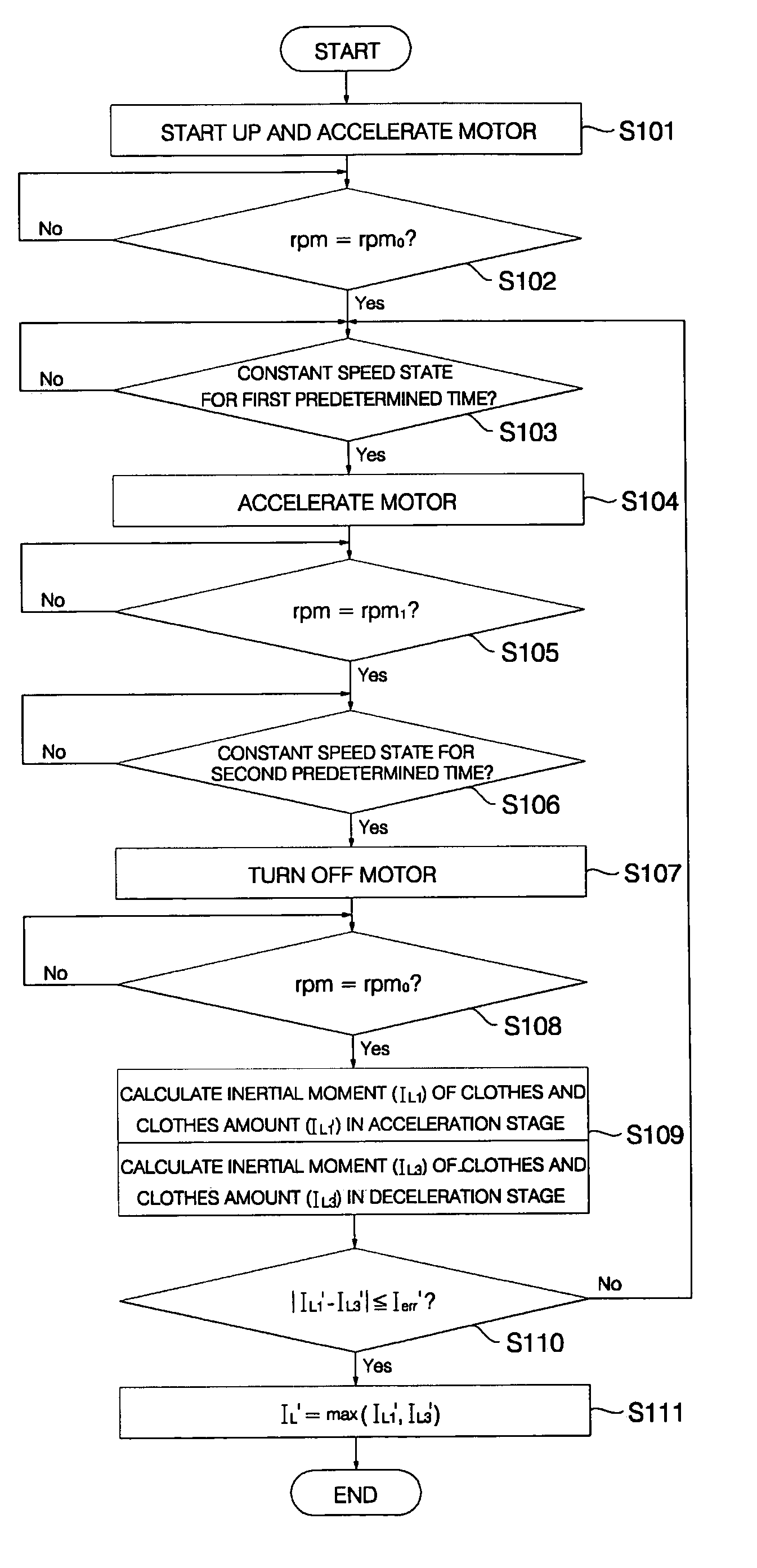

In accordance with the clothes amount sensing method according to the present invention, as shown in FIGS. 5 and 6, the motor 30 is first started up, and is then accelerated (S101). When the RPM of the motor 30 reaches a first predetermined RPM rpm0, for example, 50 rpm, the motor 30 is maintained at the first predetermined RPM rpm0 (S102).

The start-up, acceleration, and maintenance at the first predetermined RPM rpmo of the motor 30, as described above, are adapted to eliminate the influence of a static frictional force, generated upon an operation of sensing a clothes amount, on the sensing of the clothes amount. It is preferred that the first predetermined RPM rpmo, correspond to an RPM sufficiently low to cause clothes m, to be washed, to come into constant contact with an inner peripheral surface of the wash tub 10.

Following the start-up, acceleration, and maintenance at the first predetermined RPM rpm0, the motor 30 is driven in a mode for determining the amount of the clot...

second embodiment

In accordance with the clothes amount sensing method according to the present invention, as shown in FIGS. 7 and 8, the motor 30 is first started up, and is then accelerated (S201). When the RPM of the motor 30 reaches a first predetermined RPM rpm0, for example, 50 rpm, the motor 30 is maintained at the first predetermined RPM rpm0 (S202).

The start-up, acceleration, and maintenance at the first predetermined RPM rpm0 of the motor 30, as described above, are adapted to eliminate the influence of a static frictional force, generated upon an operation of sensing a clothes amount, on the sensing of the clothes amount. It is preferred that the first predetermined RPM rpm0, correspond to an RPM sufficiently low to cause clothes m, to be washed, to come into constant contact with the inner peripheral surface of the wash tub 20.

Following the start-up, acceleration, and maintenance at the first predetermined RPM rpm0, the motor 30 is driven in a mode for determining the amount of the clo...

third embodiment

In accordance with the clothes amount sensing method according to the present invention, as shown in FIGS. 12 and 13, the control unit 49 first starts up the motor 30, and then accelerates the motor 30 until the RPM of the motor 30 reaches a predetermined RPM rpm1, for example, 130 rpm (acceleration stage Stage 1)(S301 and S302).

When the RPM of the motor 30 reaches the predetermined RPM rpm1, the control unit 49 maintains the motor 30 at the predetermined RPM rpm0for a predetermined time At (constant-speed stage Stage 2) (S303).

After maintaining the motor 30 at the predetermined RPM rpm0 for the predetermined time Δt, the control unit 49 turns off the motor 30, and controls the braking unit 50 to perform a braking operation involving generation of electricity. As the motor 30 is braked in accordance with the braking operation, it is decelerated (deceleration stage Stage 3) (S304 and S305).

In accordance with the clothes amount sensing method according to the third embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com