Huber needle with anti-rebound safety mechanism

a safety mechanism and huber needle technology, applied in the field of medical needle devices, can solve the problems of huber needles being stuck on the huber needle rebound, requiring a large amount of force during huber needle withdrawal to overcome the resistance of the port's septum, and presenting a high risk of pathogen transmission, so as to prevent needle-stick injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0095] First, although the safety needle device 110 of the second embodiment may utilize a similar or identical needle housing 18 as described above, it may alternatively display its own unique type of needle housing 118 which is aesthetically different therefrom. Such needle housing 118 is exemplified in FIG. 16 and as can be seen from that figure, its outer shape or configuration is substantially similar as its counterpart shown in FIG. 11. One major difference between them, however, is that the needle housing 118 of FIG. 16 eliminates the need for any finger-graspable projections 30 and rather provides a substantially continuous and smooth outer surface in lieu thereof. Furthermore, the needle housing 118 is preferably fabricated from a plastic material and may optionally characterize a transparent or semi-transparent body.

[0096] As illustrated in FIGS. 14 and 15, the safety needle device 110 of the second embodiment additionally utilizes a different type of proximal tip componen...

third embodiment

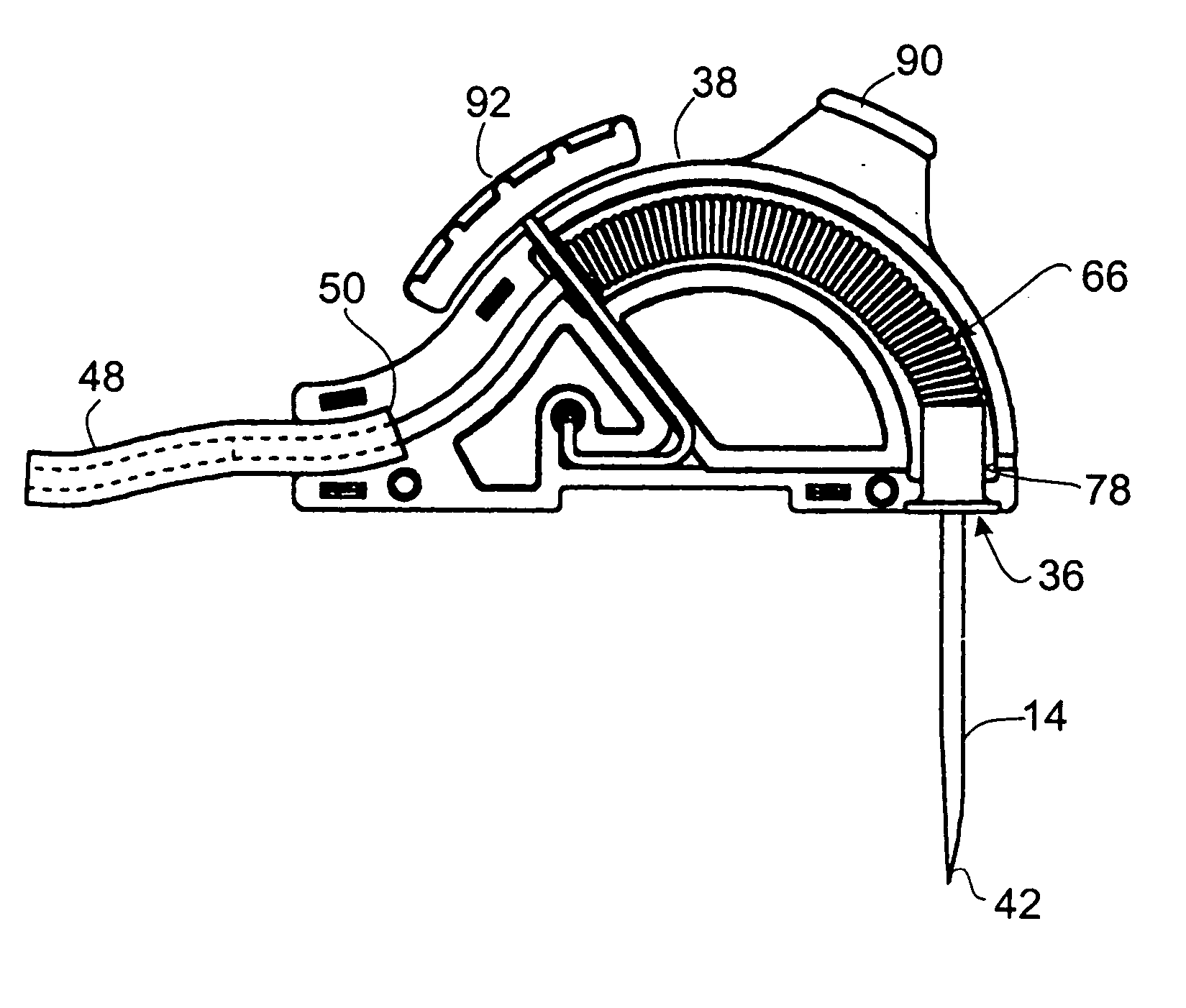

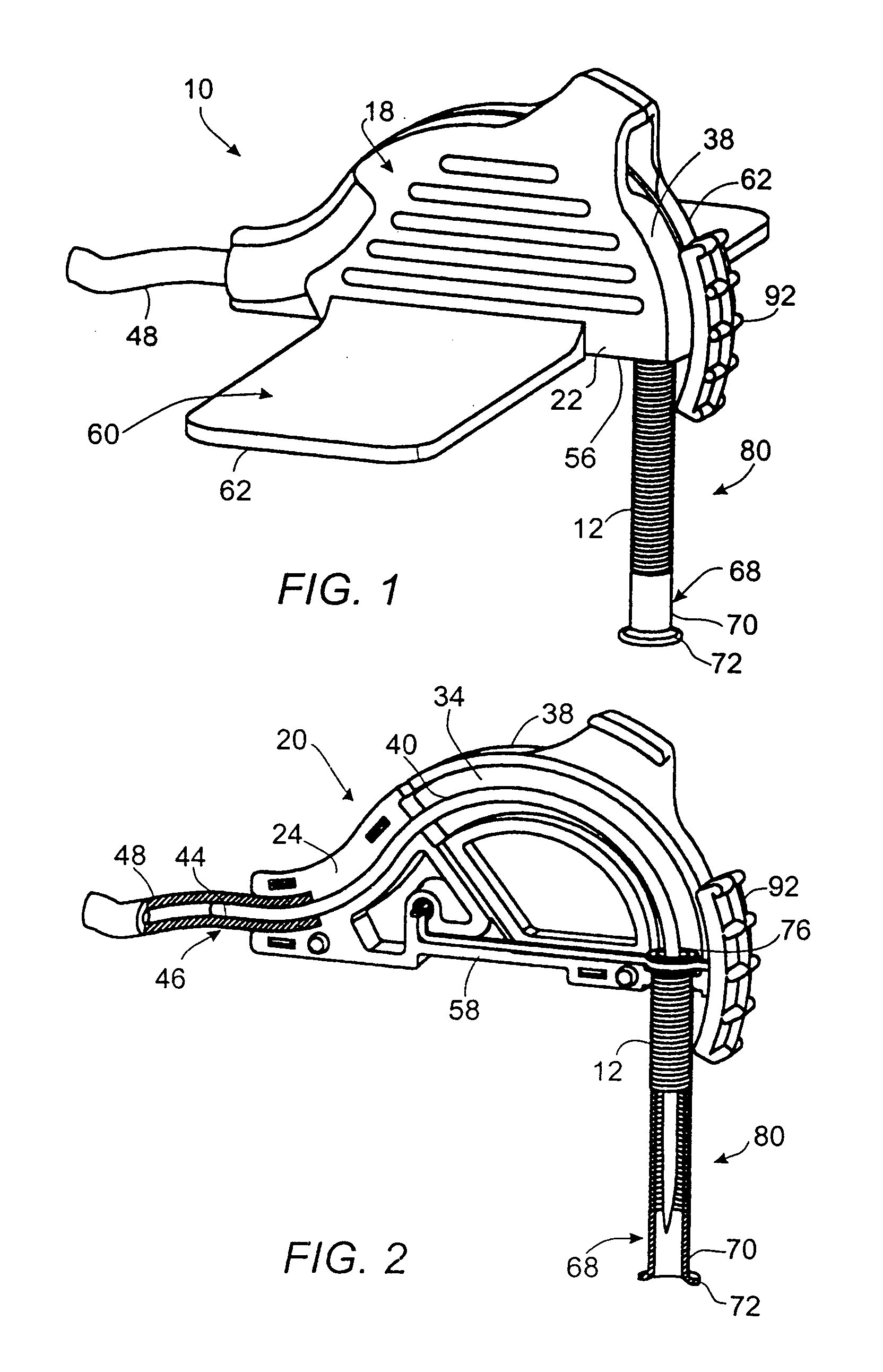

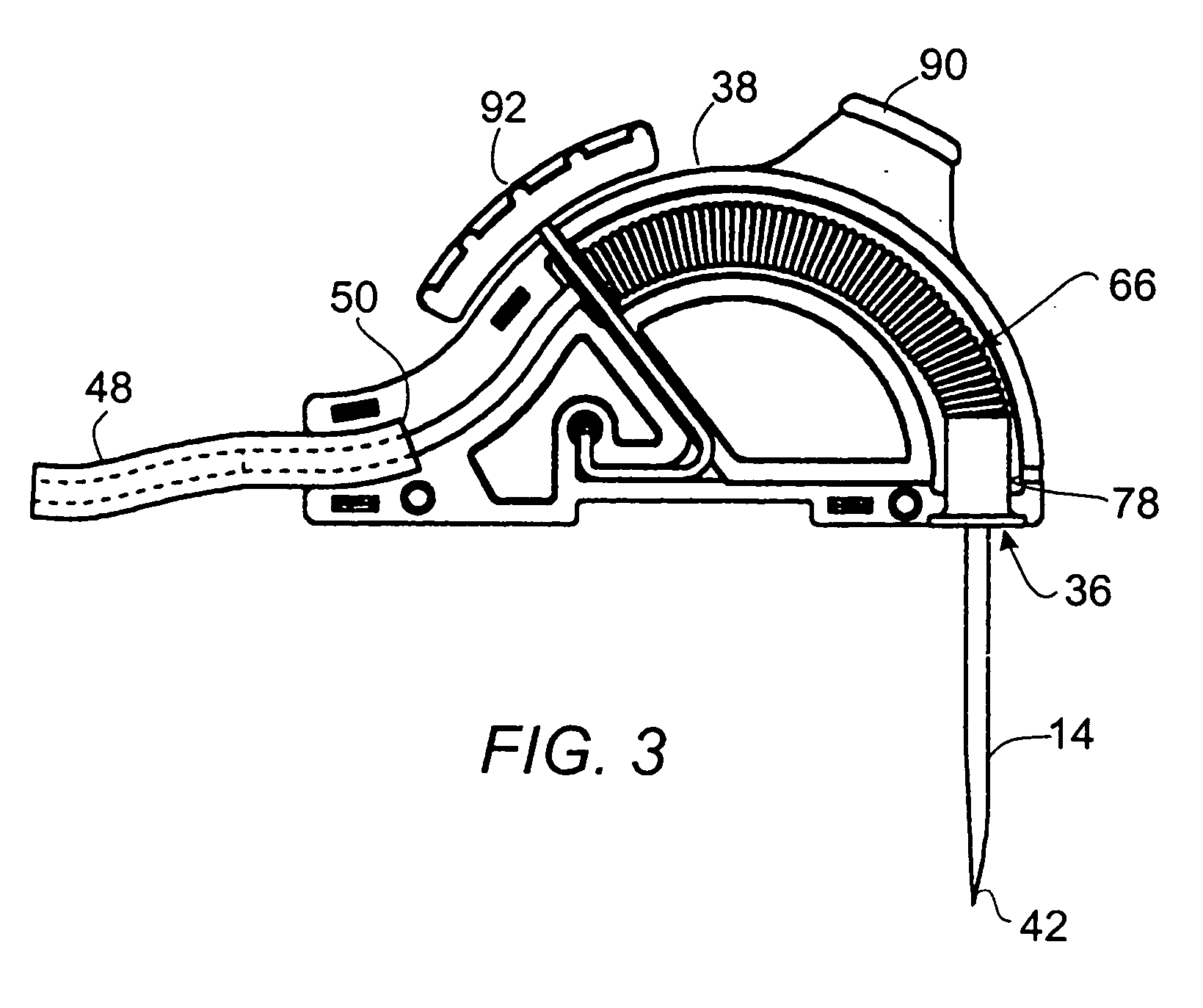

[0104] Referring now to FIGS. 17 and 19, there is shown another passive safety needle device 150 which is constructed in accordance with a third preferred embodiment of the present invention. The passive safety needle device 150 of the third embodiment is essentially a modified version of the previously defined needle devices 10, 110 and is designed to perform the same function (i.e., deter needle-stick injuries). However, as will be explained below, a different sheath releasing concept is employed for covering the needle 152 in order to protect its users against the dangers of needle-stick injuries.

[0105] But prior to describing the specifics of such unique sheath releasing concept, it should be briefly pointed out herein that the needle housing 154 of the third embodied safety needle device 150 may optionally comprise a layer of padding 156 underneath so as to increase its user-friendliness (e.g., provide softening cushion upon user's chest) during needle applications. However, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com