Transport apparatus

a technology for transporting equipment and pallets, which is applied in the field of freight containers, can solve the problems of limiting the nature of the cargo that can be carried on the return journey, and is easy to use, and achieves the effects of facilitating the loading of large or bulky cargoes, reducing the likelihood of contact, and facilitating the movement of pallets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

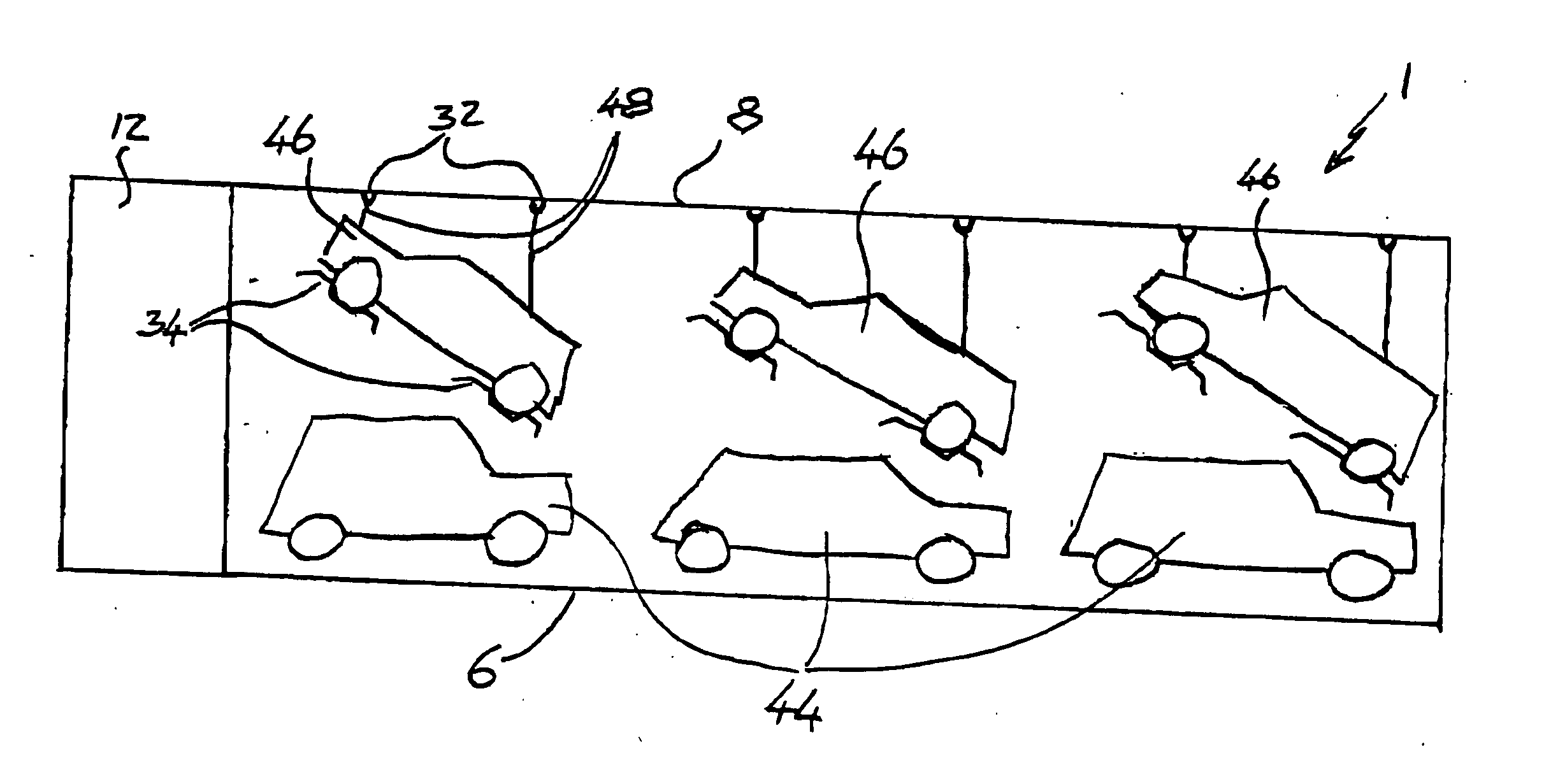

[0041]FIG. 1 shows a perspective view of a freight container 1. The freight container includes side walls 2,4 a floor 6 and a roof 8. At an end 10 of the container there are doors 12 which may be opened to allow end loading of the freight container 1.

[0042] The freight container 1 includes handling points 14 to allow the container 1 to be lifted by standard lifting machinery that may be used on docks or other loading areas.

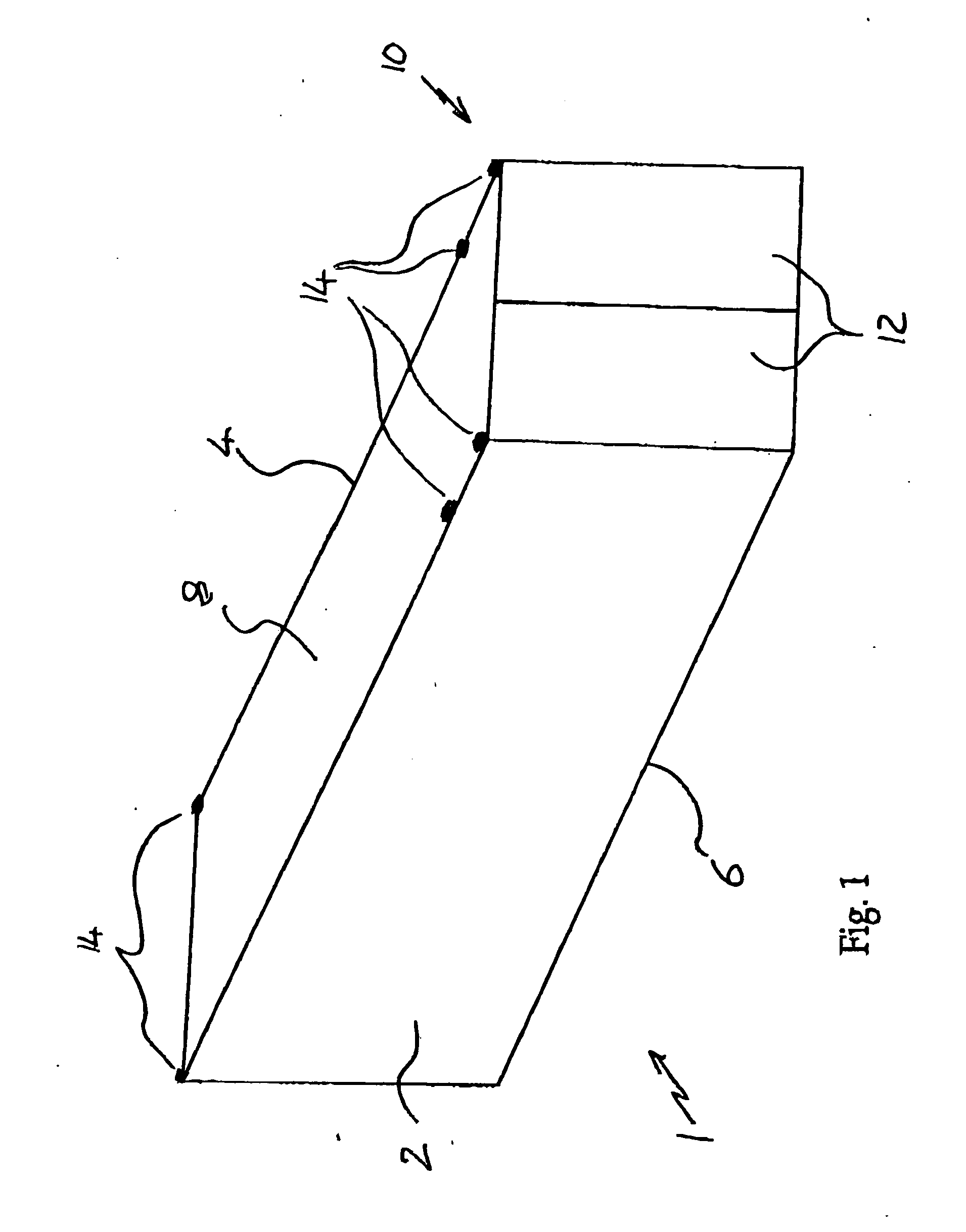

[0043]FIG. 2 show a portion of the inside of the side wall 4. The wall is corrugated, having a plurality of inner corrugation sections 16 and outer corrugation sections 18 connected by side corrugation sections 20. In this case the angles between the side corrugation sections 20 and the inner 16 and outer 18 corrugation sections is substantially 90°. Tie down rings 42 are provided at a lower portion of the wall to allow cargo to be secured relative to the container 1.

[0044] The wall includes a load carrying column 22. The column 22 comprises a ‘U’ shaped metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com