Renewable fuel mixture

a fuel mixture and renewable technology, applied in the direction of biofuels, fuel additives, liquid carbonaceous fuels, etc., can solve the problems of increasing the demand for heating oil, wasting energy, and wasting resources,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

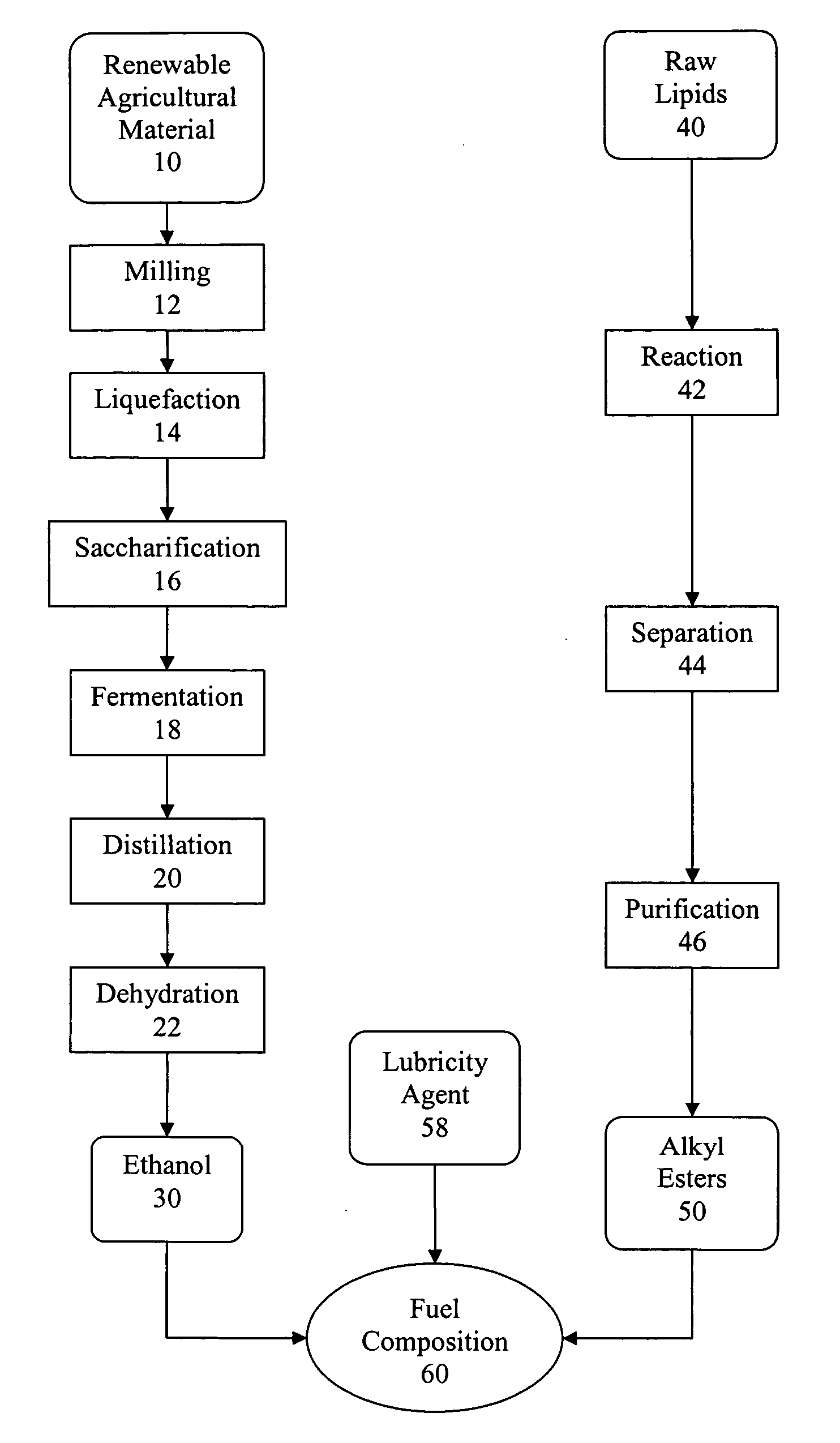

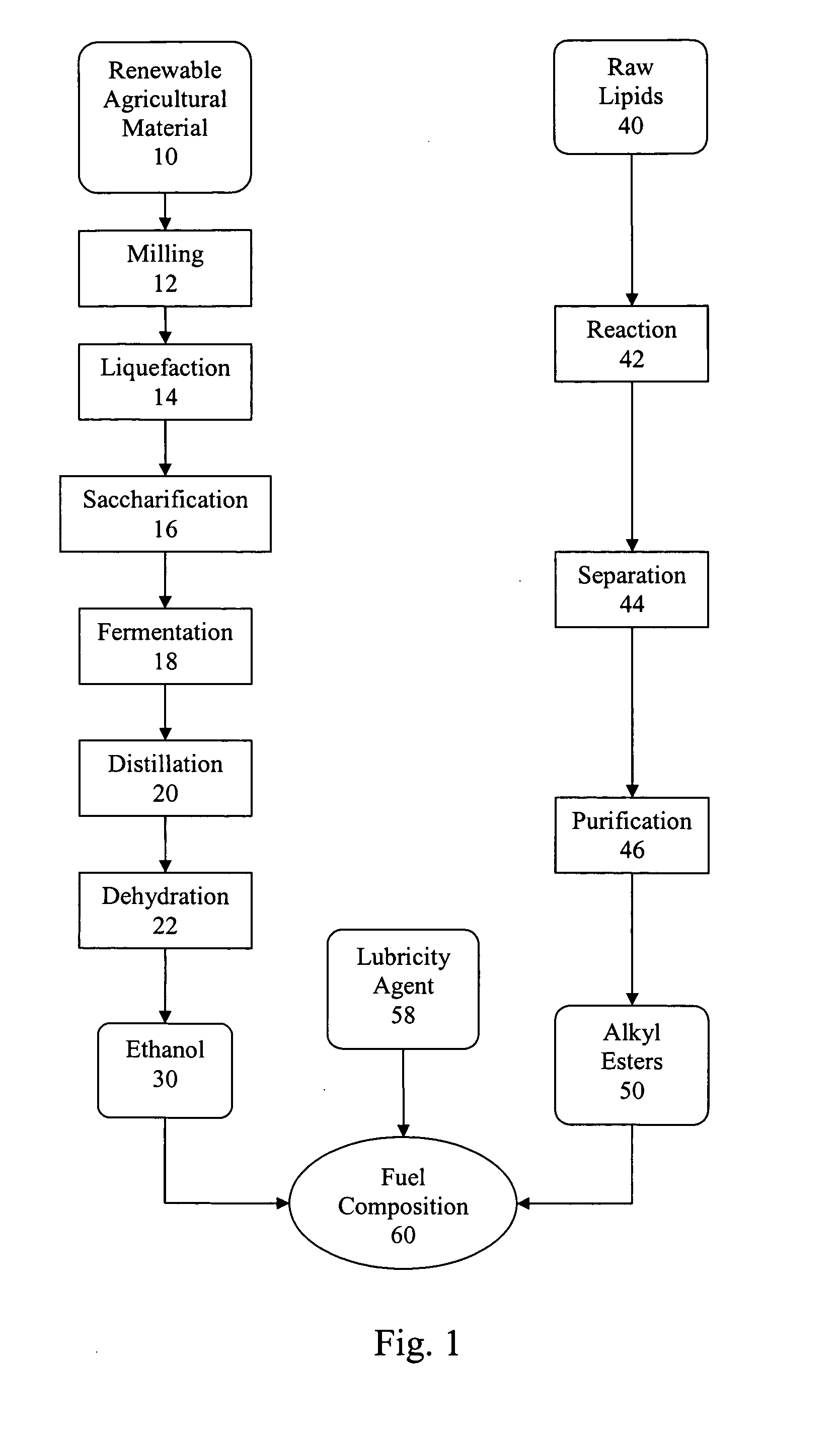

is hereafter described with specific reference being made to the drawing.

[0014] FIG. 1 is a flowchart depicting a process that may be used to obtain the composition.

[0015] While this composition may be embodied in many different forms, there are described in detail herein specific preferred embodiments. This description is an exemplification of the principles of the invention and is not intended to limit the invention to the particular embodiments described.

[0016] The present inventive fuel composition 60 comprises a mixture of ethanol 30 and alkyl esters 50. A preferred embodiment of the fuel composition 60 comprises 95% anhydrous ethanol and 5% B100 biodiesel by volume. The composition according to this ratio may have the following characteristics:

1 Auto Ignition Temperature 683.degree. F. Boiling Temperature 78.degree. C. Flashpoint 48.degree. F. Specific Gravity .785 BTUs per Gallon 65000

[0017] The fuel composition 60 has been found to be a desirable alternative to fossil fuel o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling Temperature | aaaaa | aaaaa |

| Boiling Temperature | aaaaa | aaaaa |

| Auto Ignition Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com