Medical valve and method of use

a technology of medical valves and valve bodies, applied in the field of closed patient access systems, can solve the problems of introducing air embolisms into patients, affecting the safety of patients,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

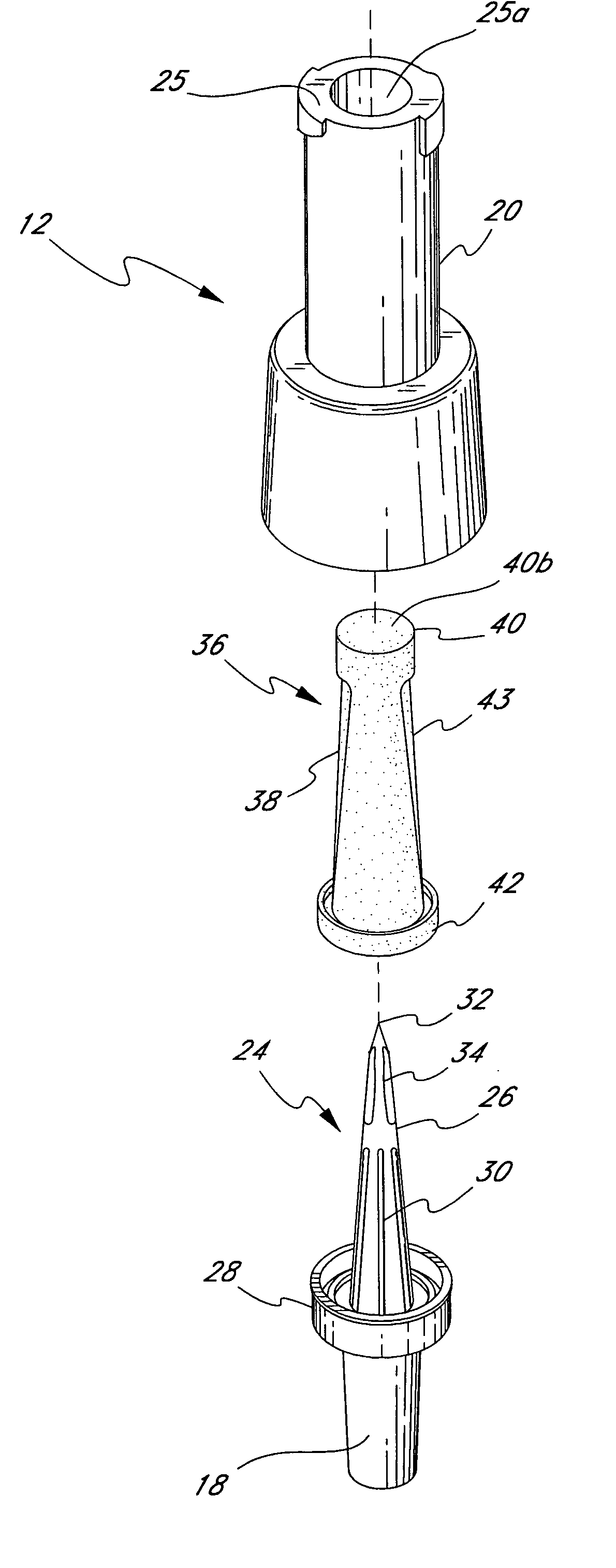

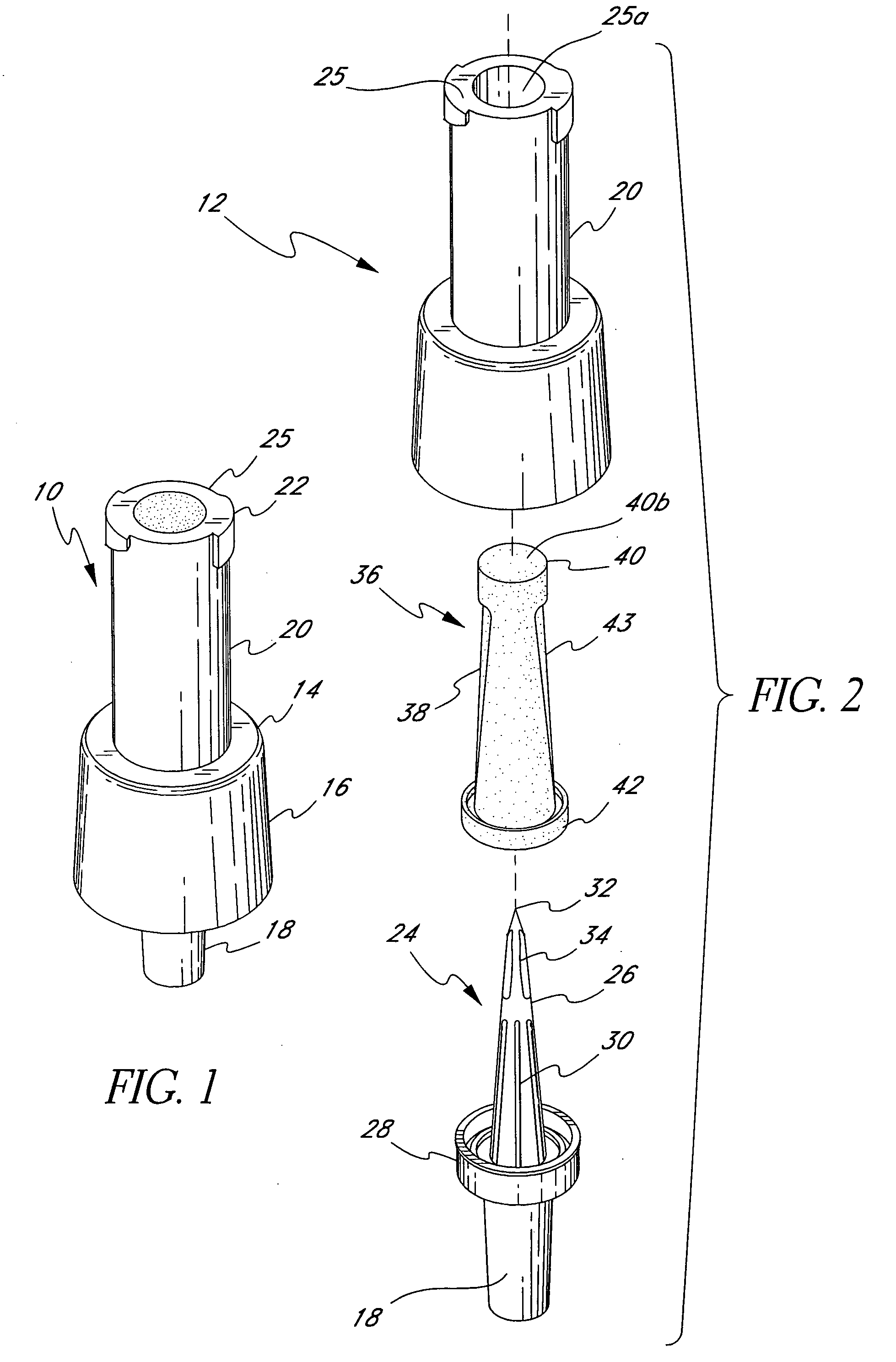

[0043] The term "proximal" is used to denote the end of the valve and other components at or near the spike tip 32 in FIGS. 2 through 5, 10 through 12, 14 and 16, and at or near the spike tip 60 in FIG. 6, and at or near the seal cap 92 in FIGS. 8, 9, 13 through 19. The term "distal" is used to denote the opposite end of the valve, or spike tip, or seal. The term "medical implement" is used to denote any medical tool known to those of skill in the art that can connect to the present invention and facilitate the passage of fluids, particularly liquids, through the instant invention. Examples of medical implements that are contemplated include, but are not limited to, tubing, conduit, syringes, IV sets (both peripheral and central lines), piggyback lines, and other components which can be used in connection with medical valve. Medical implements are commercially available in standard sized. Thus, either or both ends of the valve of this invention can be provided with fittings to accom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com