Impeller assembly for centrifugal pumps

a centrifugal pump and assembly technology, applied in the direction of liquid fuel engines, vessel construction, marine propulsion, etc., can solve the problems of inability the time period required to complete the self-priming process of centrifugal pumps may be undesired long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

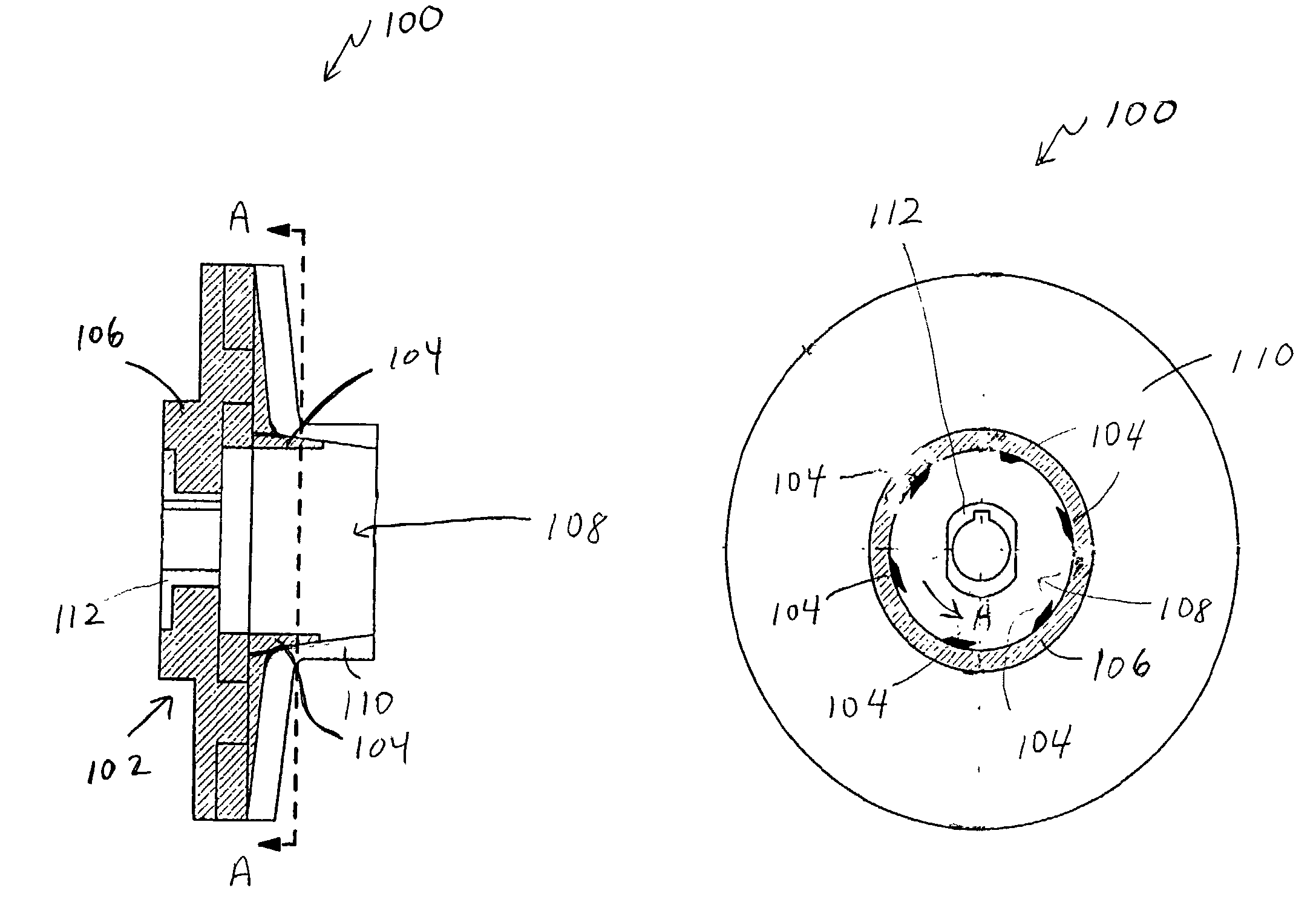

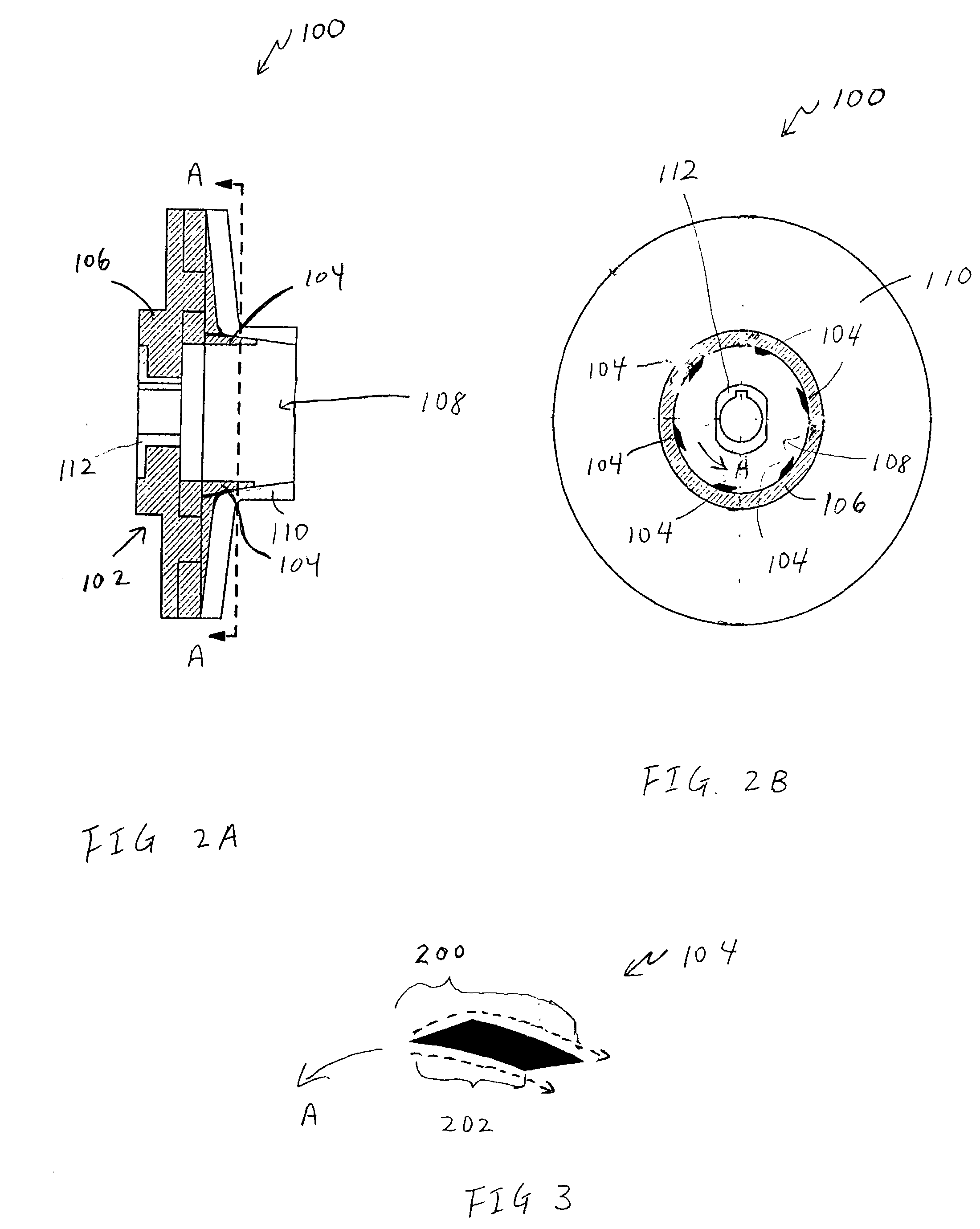

[0019] FIGS. 2A and 2B are simplified depictions of an impeller assembly 100 for use in a centrifugal pump in accordance with one exemplary embodiment of the present invention. Impeller assembly 100 includes an impeller 102 and six winglets 104 (shown in cross-section in FIG. 3). Impeller 102 includes a first impeller body 106 with an eye opening 108 therein, a second impeller body 110 (through which eye opening 108 also passes) and a keyway 112. Eye opening 108 is configured for the passage of fluid (e.g., water) therethrough when impeller assembly 100 is in use in a centrifugal pump.

[0020] Winglets 104 are configured to protrude within eye opening 108 (see, for example, FIG. 2B) of impeller 102 and are also configured for movement in a predetermined pattern (e.g., the circular pattern indicated by arrow A of FIGS. 2B and 3) when impeller assembly 100 is in use in a centrifugal pump.

[0021] Referring to FIGS. 4A-4C, first impeller body 106 includes six curved vanes 114 disposed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com