Fluid levitated caster integrating external debris scraper

a technology of fluid levitation and scraper, which is applied in the direction of manual conveyance devices, vehicle components, transportation and packaging, etc., can solve the problems of surprisingly low force required to move the levitation load, affecting the performance of the levitation membrane,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

with Preferred Scraper Ring Configuration

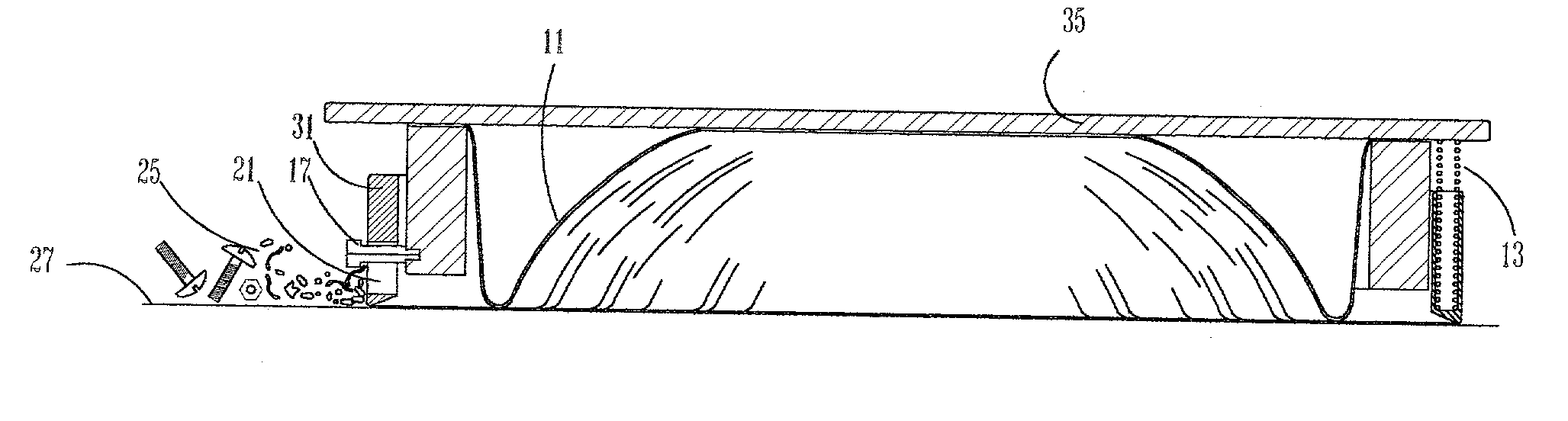

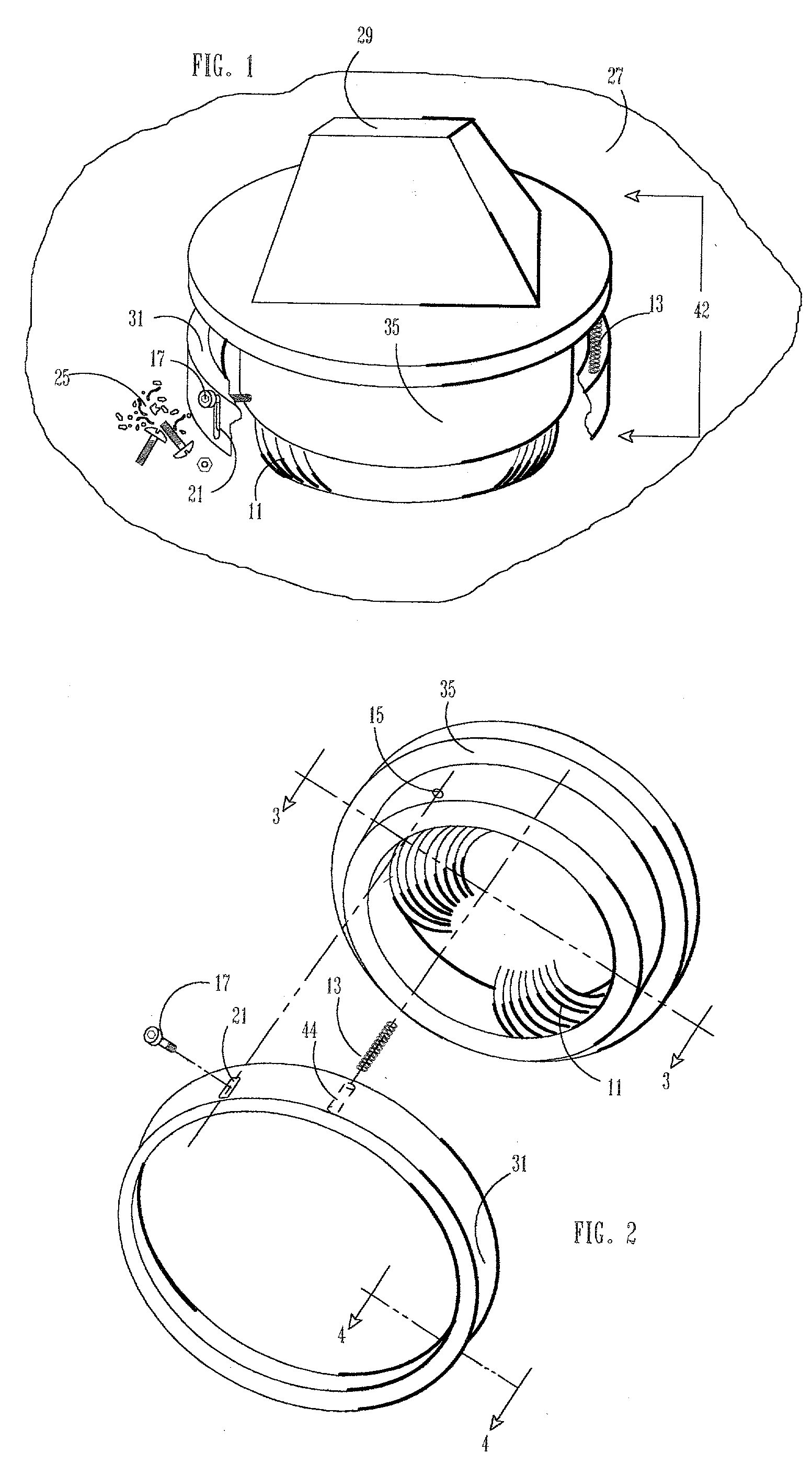

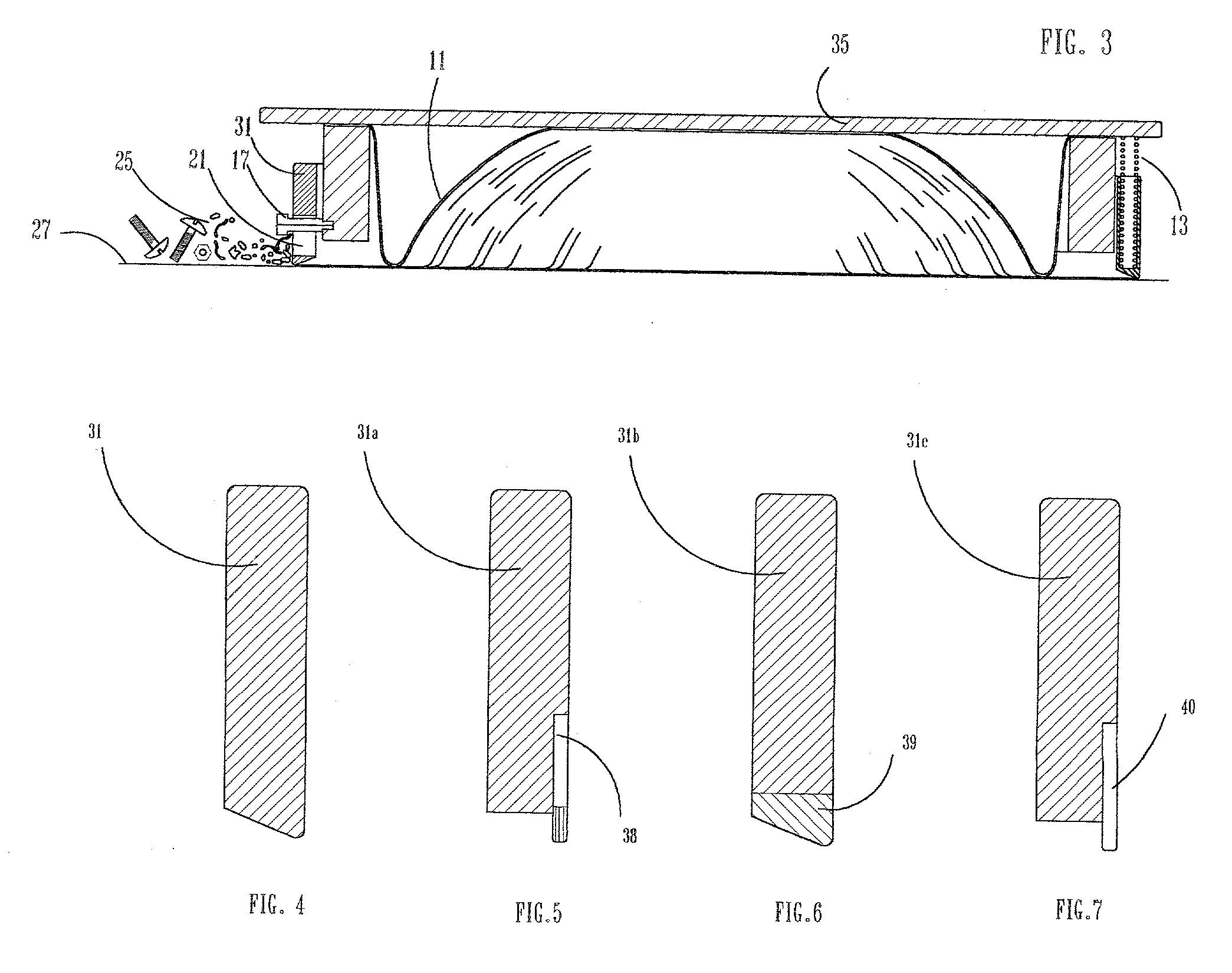

[0023] The view of FIG. 1 shows my invention "fluid levitated caster integrating external debris scraper" referred to as assembly 42. Assembly 42 is shown positioned beneath a heavy load 29 that is to be moved across a floor 27. Shown on floor 27 is debris 25. Assembly 42 includes a frame 35, a levitation membrane 11, and a scraper ring 31. Frame 35 has on it's periphery a series of tapped holes 15 shown in the view of FIG. 2. Returning to the view of FIG. 1, scraper ring 31 includes through it's wall a series of slots 21, the quantity and position of which matches tapped holes 15. A series of attachment screws 17 position within slots 21 and secure into tapped holes 15. Via this preferred design configuration, scraper ring 31 is free to move vertically within the limits of slot 21 and attachment screw 17 travel. Vertical scraper ring 31 travel is necessary as levitation membrane 11 inflates, deflates, and moves vertically during normal opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com