Watertight housing for electrical devices

a technology for electrical devices and housings, applied in the field of boxes and housings, can solve the problems of narrow gaskets, difficult and expensive production, and four screw holes occupying limited housing spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] 1. Description of One Embodiment of the Invention

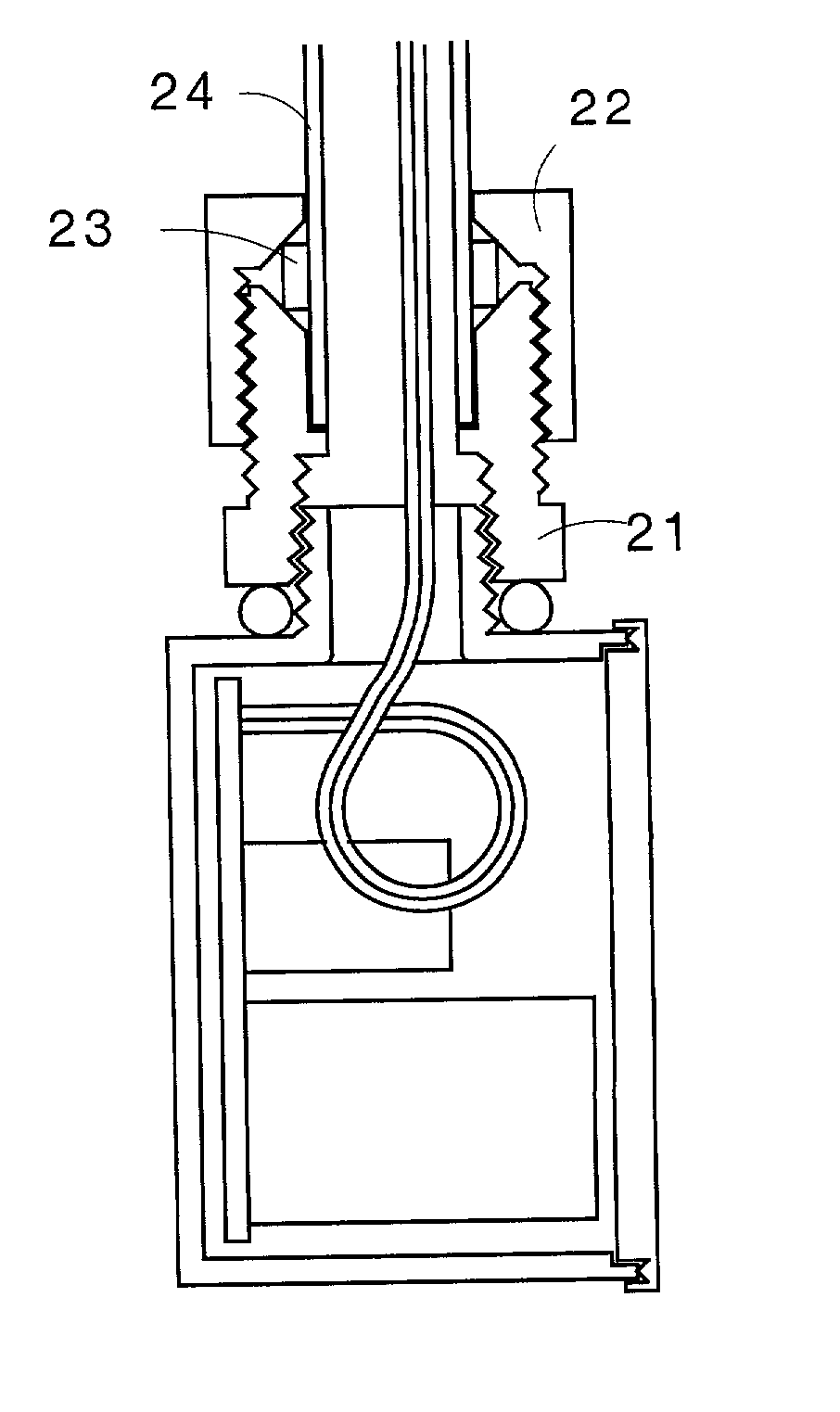

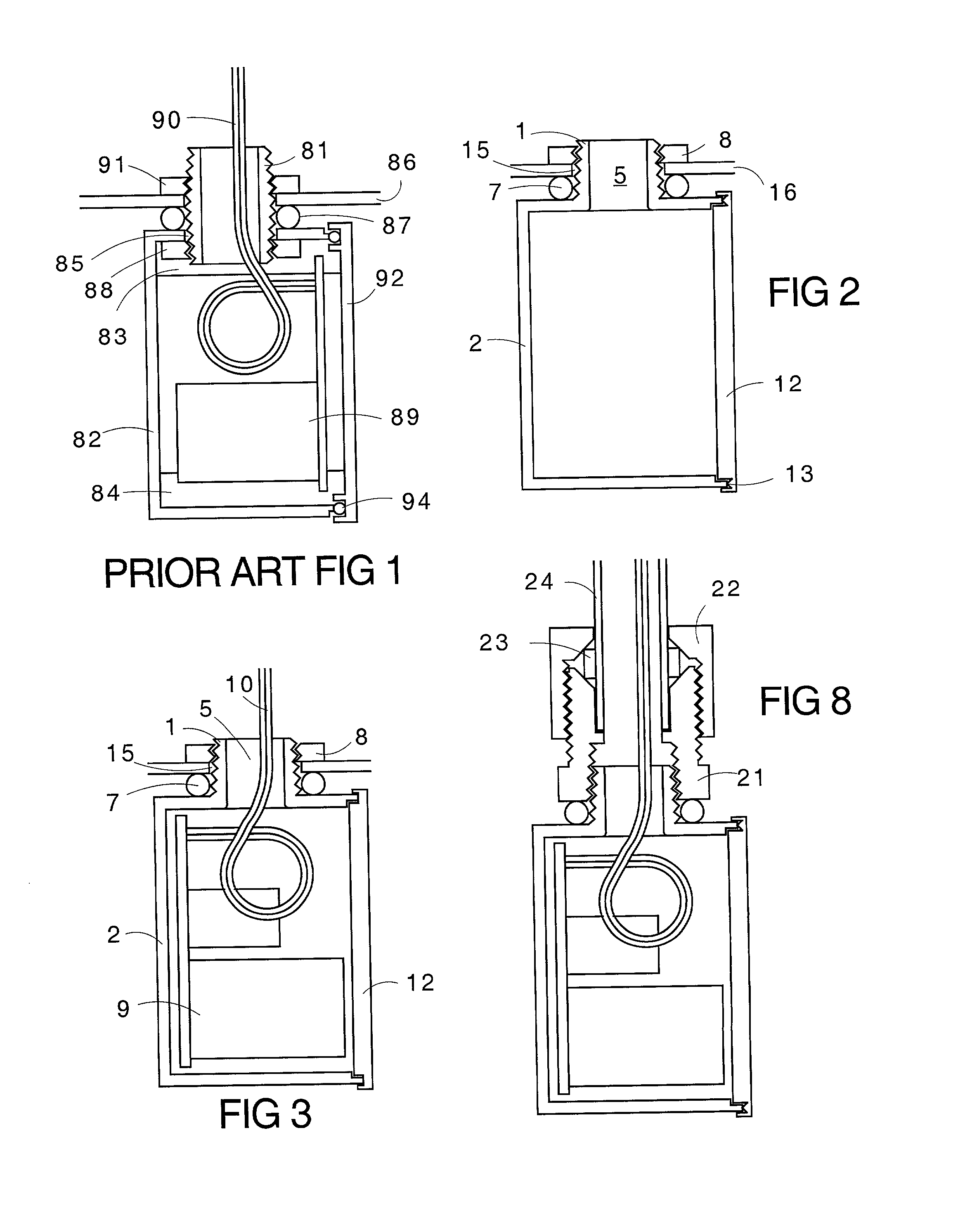

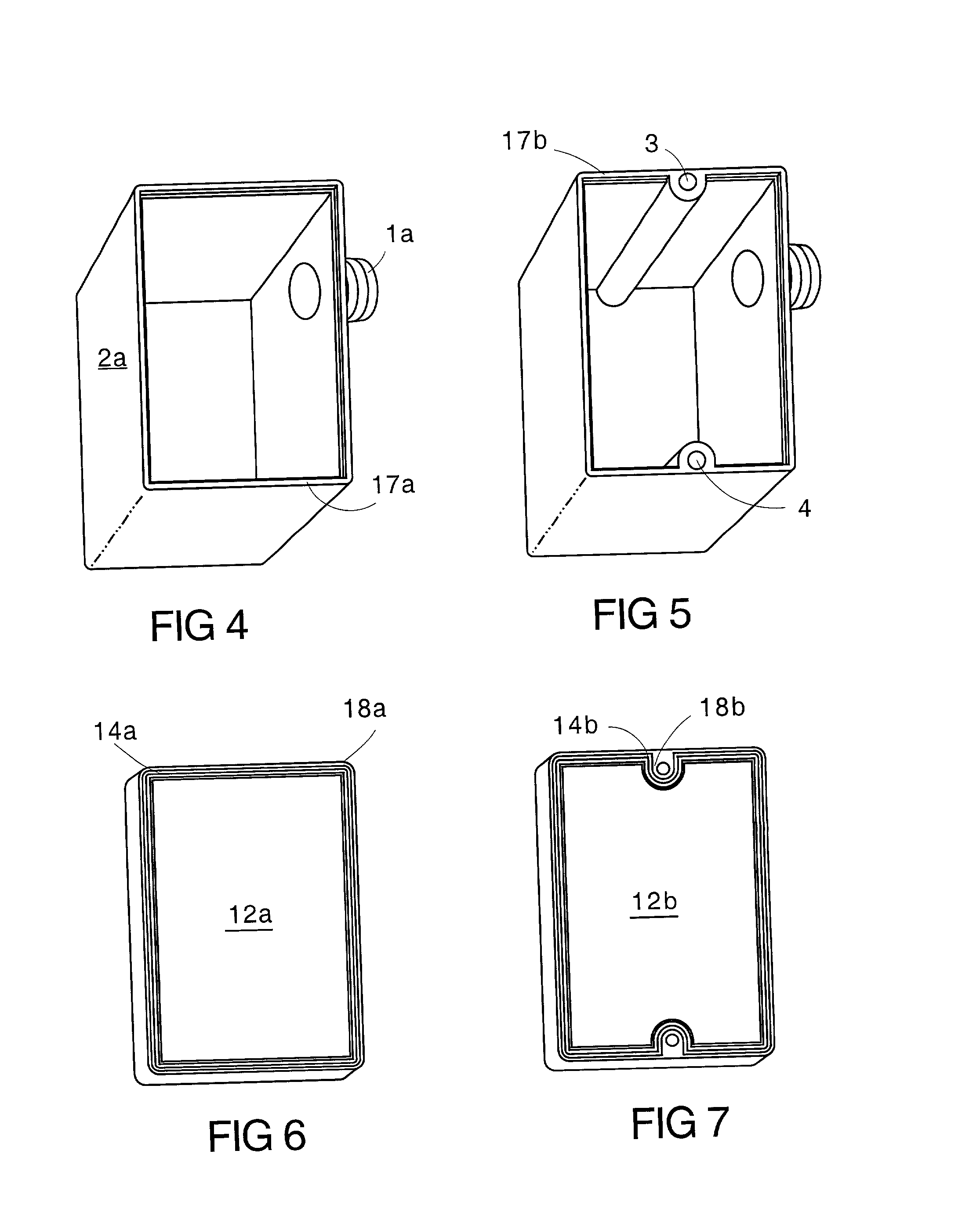

[0064] FIG. 2 shows an installed watertight enclosure / housing-to-junction box attachment, cross-sectional view. The enclosure / housing has housing base 2 with fixed male nipple 1, lid 12, and friction-induced weld 13. Prior-art nut 8, washer 7, junction box 16, and junction box knock-out 15 are noted. Weld 13 is actually drawn as the point of an energy director before a weld.

[0065] FIG. 3 shows the embodiment of FIG. 2 with an electrical device. The manufacturer simply places washer 7 over nipple 1, feeds wire(s) 10 through opening 5 of nipple 1, lowers electrical device 9 into base. 2, and bonds lid 12 onto base 2. The installer punches / drills out box knockout 15, slips nipple 1 into the knock-out, slips on / screws down nut 8, then connects the free end of wire(s) 10 (often to junction box terminals).

[0066] The washer forms a seal between the junction box and the face of the housing, concluding a water-tight seal for the housed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com