Single step process for blanket-selective cvd aluminum deposition

a single-step process and aluminum deposition technology, applied in the direction of semiconductor/solid-state device details, transportation and packaging, vacuum evaporation coating, etc., can solve the problem of high aspect ratio, increased difficulty in void-see filling of the aperture without voids, and compromised devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

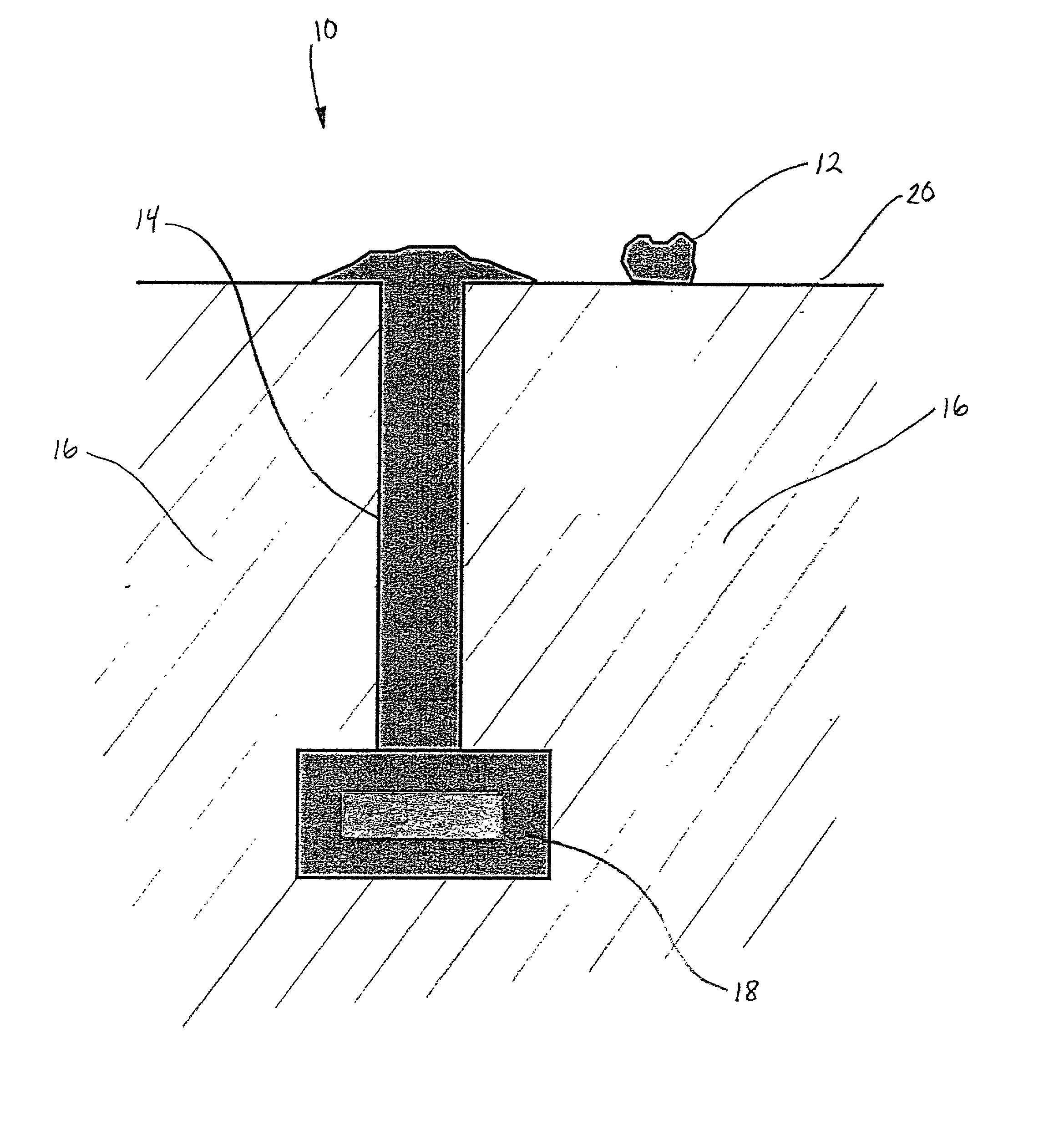

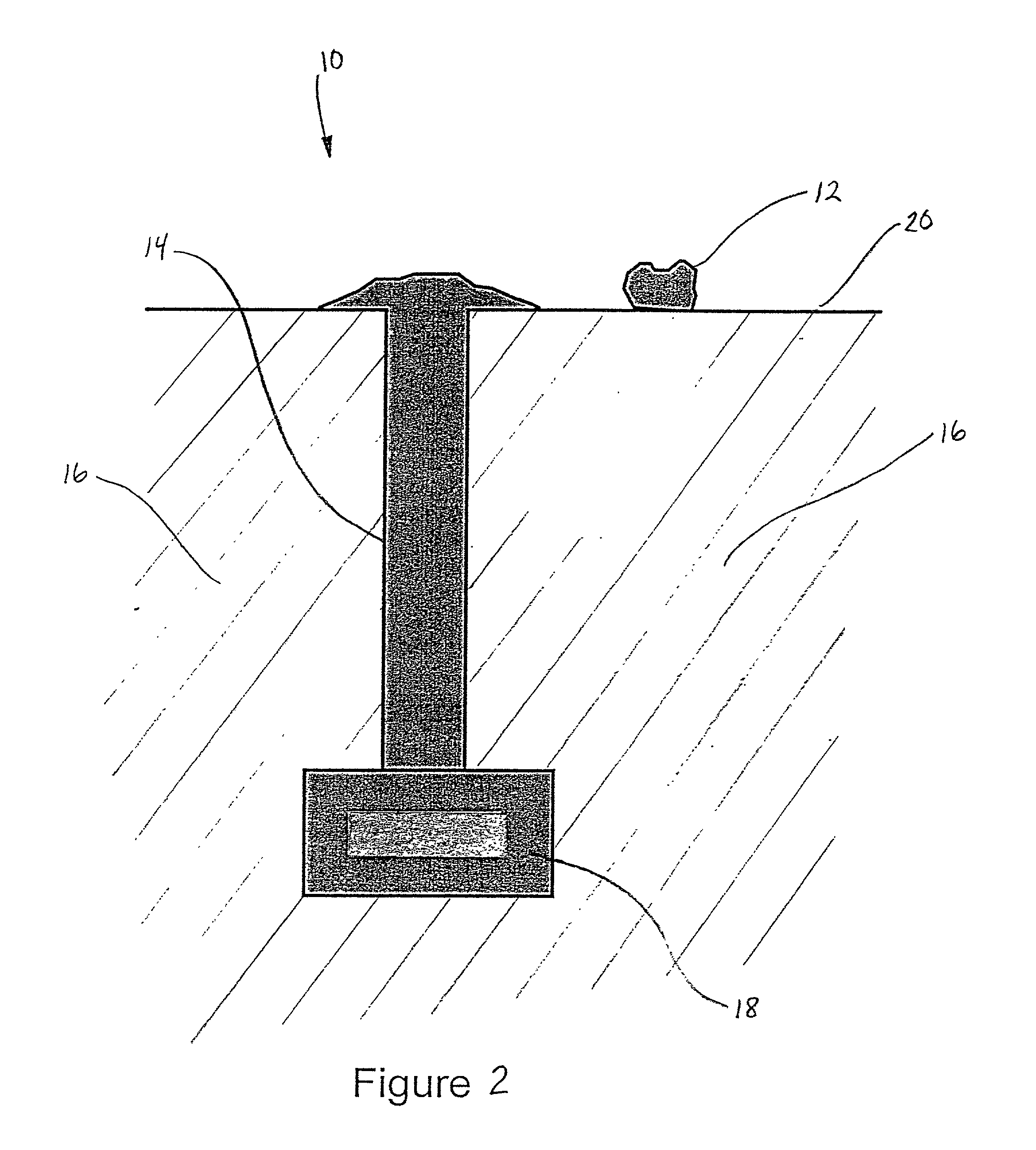

[0025] The present invention provides a simple process and apparatus for the selective deposition of material within sa geometries, such as small apertures which will form vias or contacts, that eliminates the loss of selectivity on the field, This process comprises the steps of (1) depositing a thin conducting layer, preferably titanium nitride (TiN). to serve as a nucleation layer over a field; (2) patterning and etching the nucleation and dielectric layers to form apertures having small geometries; and (3) depositing CVD metal over the she to provide selective grow of the metal within the small geometries and, preferably, simultaneous uniform growth on the field, Accordingly, the present invention provides a method and apparatus for void-free filling of small geometries with a reduced number of processing steps and preventing the formation of nodules on the field.

[0026] Referring to FIG. 3, a cross-sectional diagram of a layered structure 30 is shown including a dielectric layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com