Acrylic elastomer and its composition

a technology of elastomer and elastomer, which is applied in the field ofacrylic elastomer, can solve the problems of no satisfactory compression set characteristics, and large amount of remaining unreacted monomers, and achieve good compression set characteristics and distinguishable vulcanization characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

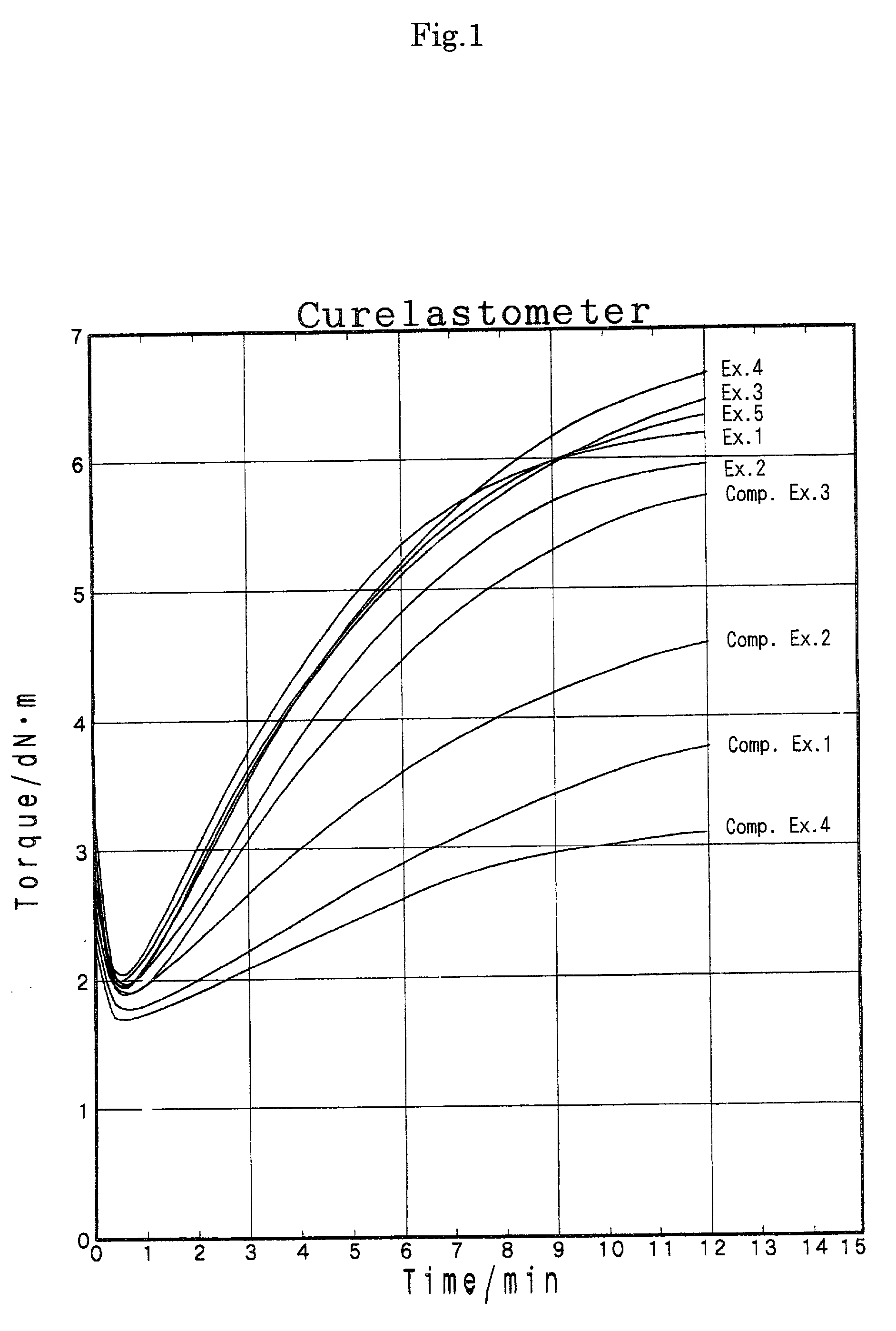

Image

Examples

reference examples 1 to 9

[0045] The following components were charged into a separable flask provided with a thermometer, a stirrer, a nitrogen gas inlet pipe and an evacuation apparatus:

1 Parts by weight Water 150 Sodium laurylsulfate 5.5 Monomer mixture given in Table 1 100

[0046] Then, the flask was subjected to repetitious of air removal and nitrogen gas flushing to thoroughly remove oxygen from the flask, and the following components were added thereto to initiate polymerization reaction at room temperature, and the reaction was continued until the polymerization conversion reached at least 90%:

2 Parts by weight Sodium formaldehyde sulfoxylate 0.002 t-Butyl hydroperoxide 0.005

[0047] The resulting aqueous latex was solidified in an aqueous sodium chloride solution, followed by water washing and drying to obtain monoalkyl maleate-copolymerized acrylic elastomer. Proportion (mol. %) of unreacted monoalkyl maleate to monoalkyl maleate copolymerized in the resulting copolymer was adjusted by controlling an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| total weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com