Method for processing and resuing carbinol waste water for circulated cooling water

A technology of circulating cooling water and methanol, applied in the direction of adsorption water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of complex operation management and large investment, and achieve advanced system technology and reduce The effect of aeration volume and stable water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

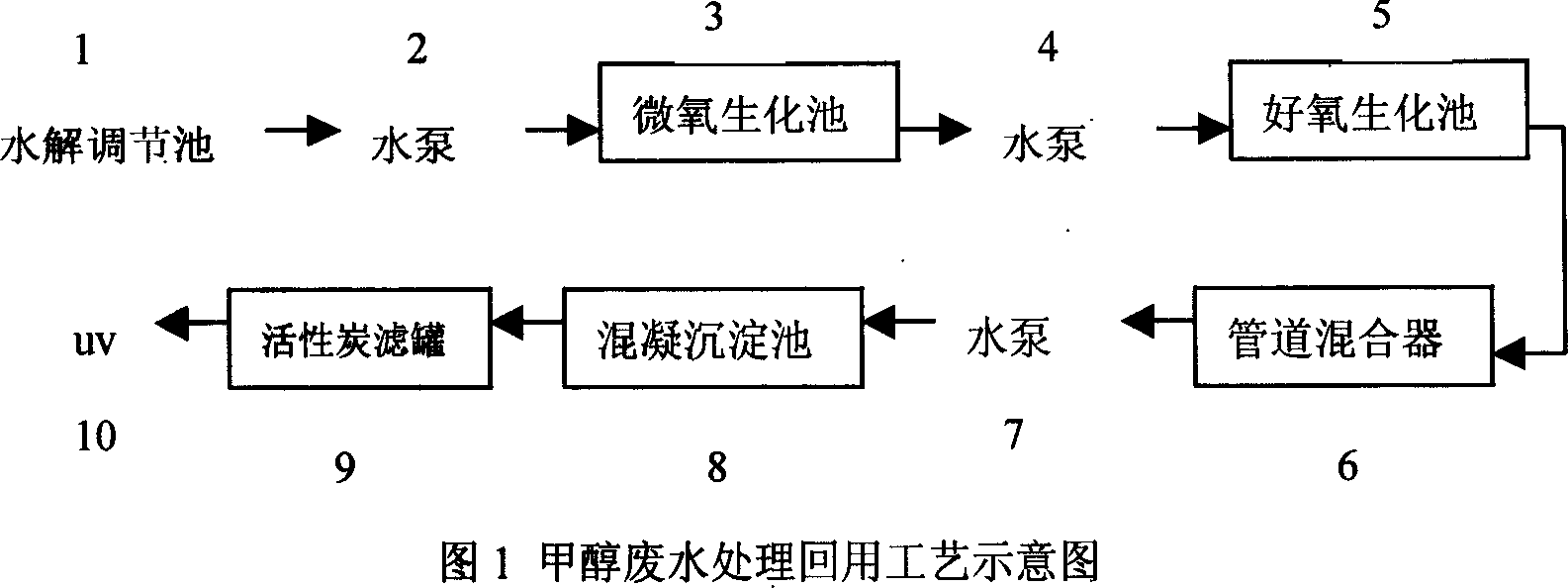

Method used

Image

Examples

Embodiment 1

[0025] Under the normal operating conditions of each process in the wastewater treatment system, the treatment effects of each wastewater treatment process after treatment are shown in Table 1.

[0026] Table 1 The running results of each process (hardness is expressed as CaCO 3 count)

[0027] Water quality project

flooded

Regulation pool

Microaerobic organisms

deal with

aerobic

biological treatment

coagulation sedimentation place

reason

BAC

reaction tower

craft

CODcr (mg / l)

Methanol (%)

pH

Turbidity (degrees)

total hardness

total alkalinity

Ca 2+ (mg / L)

CI - (mg / L)

T-P(mg / L)

NH 3 -N (mg / L)

Total number of bacteria

(piece / mL)

456

3.7

9.1

24.3

198

177

135

31

70

1.94

0.7

Winter 8×10 6

Summer 3×10 7

403

2.2

7.7

26

187

169 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com