Temperature sensor needless accurate heating-up temperature control device and method

A temperature sensor, heating temperature technology, applied in temperature control, temperature control by electric method, thermometer, etc., can solve the problems of low temperature control accuracy and repeatability, affecting the results of resistance measurement by bridge method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

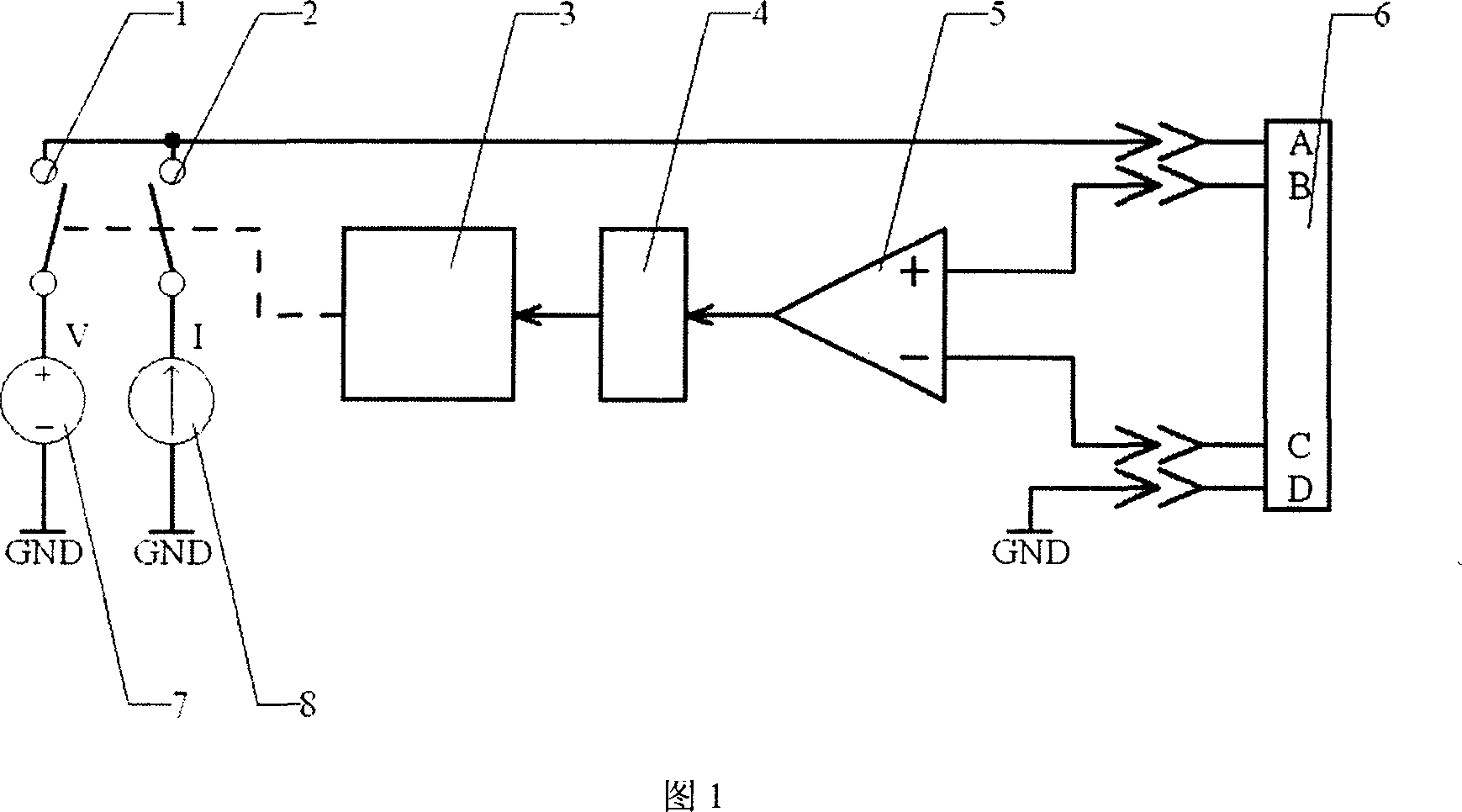

[0009] Fig. 1 is a schematic diagram of the system structure of the present invention. The controller (3) compares the detected actual temperature with the target temperature, and determines the actions of the heating switch (1) and the detection switch (2), so as to maintain the temperature of the heating element (6) within a certain accuracy range above and below the target temperature Inside. In the figure, the constant voltage source (7) provides heating energy for the heating element (6), and the precision constant current source (8) provides the heating element (6) with precise current for detection. A and D are two points with the farthest effective distance on the heating element (6), so that the heating element can be fully utilized. B is the position between A and D as close to A as possible, and C is the position between A and D as close to D as possible, so that the signal that can be detected between B and C is the largest. The result obtained by subtracting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com