Micro capsule no-aids free water washing dyeing process and device

A dyeing device and microcapsule technology, which can be used in the treatment of textile material dyeing devices, dyeing methods, textiles and papermaking, etc., which can solve the problems of difficult removal of microcapsules and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: sample dyeing test of polyester

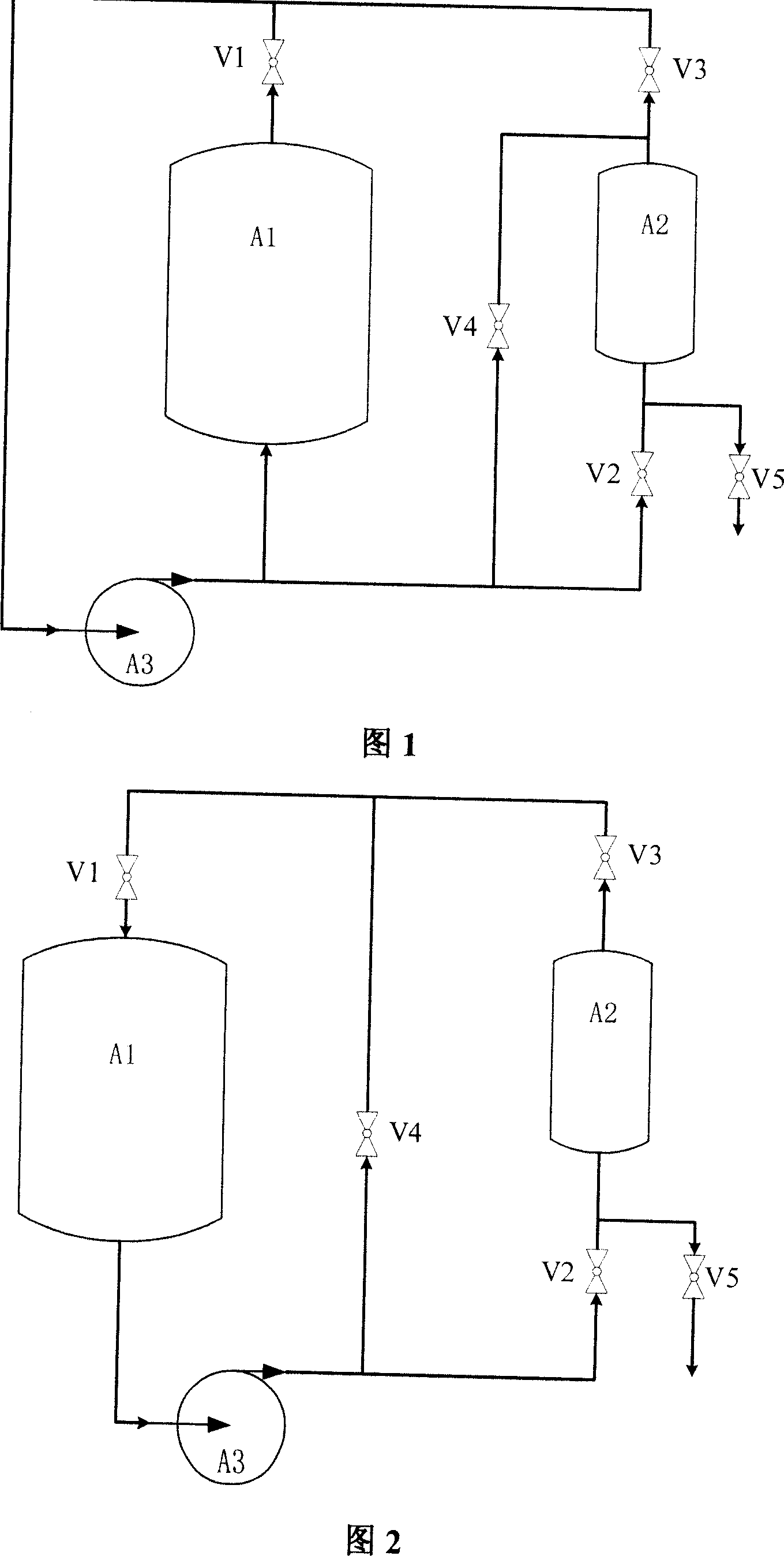

[0043] The selected equipment is: 1. Ordinary high-temperature and high-pressure overflow dyeing machine, with a capacity of 20kg, a maximum working temperature of 140°C, and a maximum working pressure of 0.4MPa; 2. The ordinary extraction machine is used as a microcapsule dyeing extraction machine, with a volume of 20L and a maximum working pressure of 0.4MPa. The temperature is 140°C, the maximum working pressure is 0.4MPa, the filter medium is a stainless steel pleated filter element, the filtration accuracy is 20 microns, and the filtration area is 2m 2 ; Connect the device in the manner shown in Figure 1.

[0044] Test materials: 1. Pure polyester cloth 1.9kg; 2. Microencapsulated disperse dye (C.I. Disperse Blue 56) 4% owf.; 3. Water 300L; 4. Proper amount of acetic acid.

[0045] Steps:

[0046] Step 1: Dyeing machine A1 enters the cloth, adds water and acetic acid to adjust the pH value of the dyeing solution to ...

Embodiment 2

[0053] Embodiment 2: polyester dyeing production

[0054] The selected equipment is: 1. Ordinary high temperature and high pressure overflow dyeing machine, capacity 200kg, maximum working temperature 140°C, maximum working pressure 0.4MPa; 2. Microcapsule dyeing extraction machine, volume L, maximum working temperature 140°C, maximum working pressure 0.4MPa, the filter medium is non-woven filter bag made of viscose fiber, the filter precision is 20 microns, and the filter area is 6m 2 ; Connect the device as shown in Figure 2.

[0055] Test materials: 1. 55 kg of pure polyester cloth; 2. Microencapsulated disperse dye (C.I. Disperse Blue 56) 2% owf.; 3. Water 1000L; 4. Amount of acetic acid.

[0056] Steps:

[0057] Step 1: Dyeing machine A1 enters the cloth, adds water and acetic acid to adjust the pH value of the dyeing solution to 5-6;

[0058] Step 2: adding the microencapsulated dye to the microcapsule dyeing extraction machine A2;

[0059] Step 3: Close the drain va...

Embodiment 3

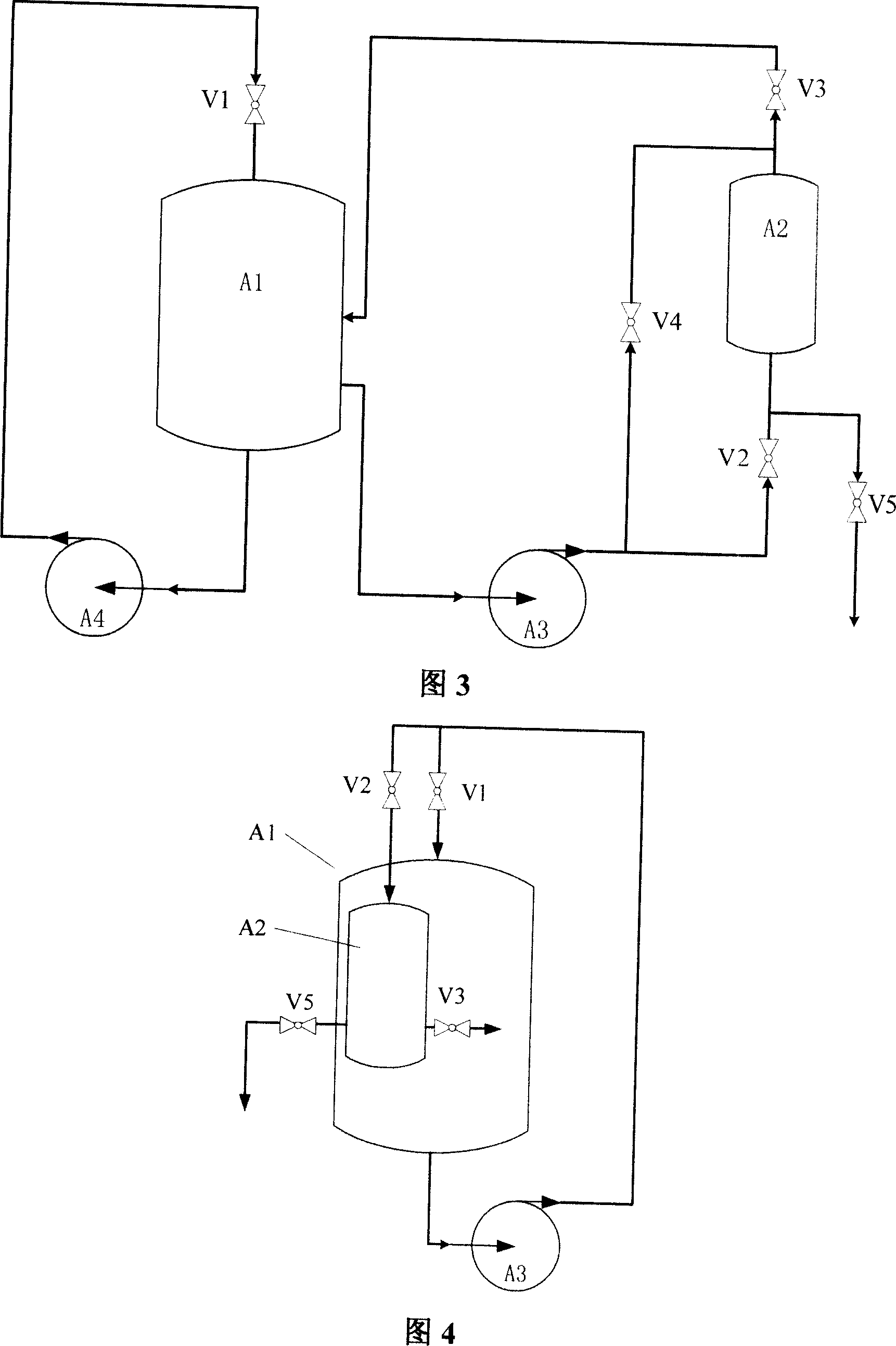

[0064] Embodiment 3: polyester yarn dyeing

[0065] The selected equipment is: 1. Ordinary high-temperature and high-pressure package dyeing machine, capacity 3kg, maximum working temperature 140°C, maximum working pressure 0.4MPa; 2. Microcapsule dyeing extraction machine, volume 6L, maximum working temperature 140°C, maximum working pressure 0.4MPa, stainless steel filter element for filter medium, filtration precision 20 microns, filtration area 0.18m 2 ; Connect the device as shown in Figure 3.

[0066] Test materials: 1. Pure polyester cheese 1kg; 2. Microencapsulated disperse dye (C.I. Disperse Blue 56) 2% owf.; 3. 20L of water; 4. Proper amount of acetic acid.

[0067] By the step operation of embodiment 1, the working flow of extraction machine A2 is 5m 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com