Dynamic damper and manufacturing method therefor

A shock absorber and ring technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problem of difficulty in increasing the bonding surface area, so as to increase the bonding surface area and simplify production. method, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

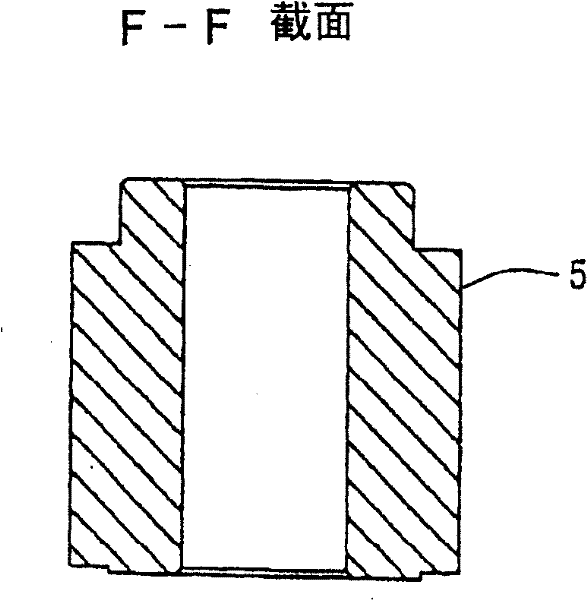

[0042] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0043] The shock absorber of the present invention is mainly press-fitted on the rotating shaft of the motor and used to absorb vibration.

[0044] In the following embodiments, an inner rotor type stepping motor used, for example, to drive a scanner of a copier, to drive a carriage of a printer, or to drive a sheet feeder of a printer is explained as an example of a motor.

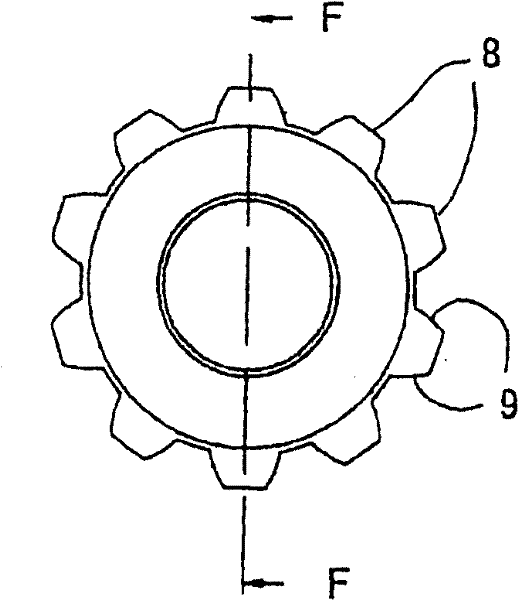

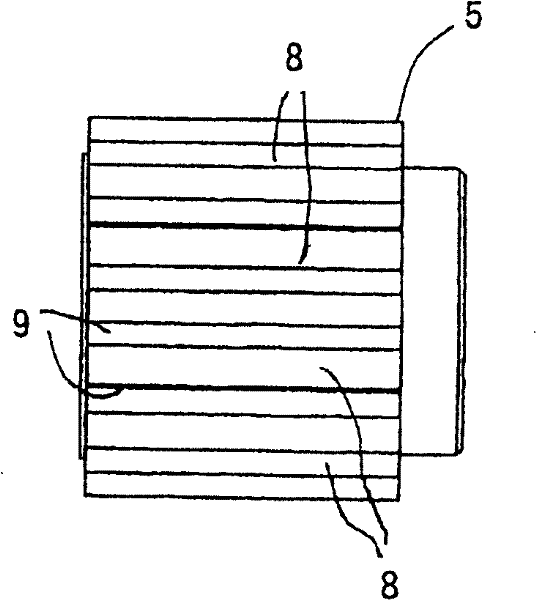

[0045] The shape of the stepping motor will refer to the figure 1 to explain.

[0046] exist figure 1 In , the rotor includes a rotor core having rotor teeth, and the rotor rotates together with a rotating shaft 1 made of a non-magnetic material. The stator includes a stator core surrounding the rotor. The stator core comprises magnetic poles which in turn have stator toothing facing the rotor toothing of the rotor core. The excitation wire is wrapped around the pole wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com