Transferring apparatus

A transmission device and track technology, applied to storage devices, packaging, conveyors, etc., can solve problems such as multiple vibrations and noises, increased running time, and reduced running speed of the conveying body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

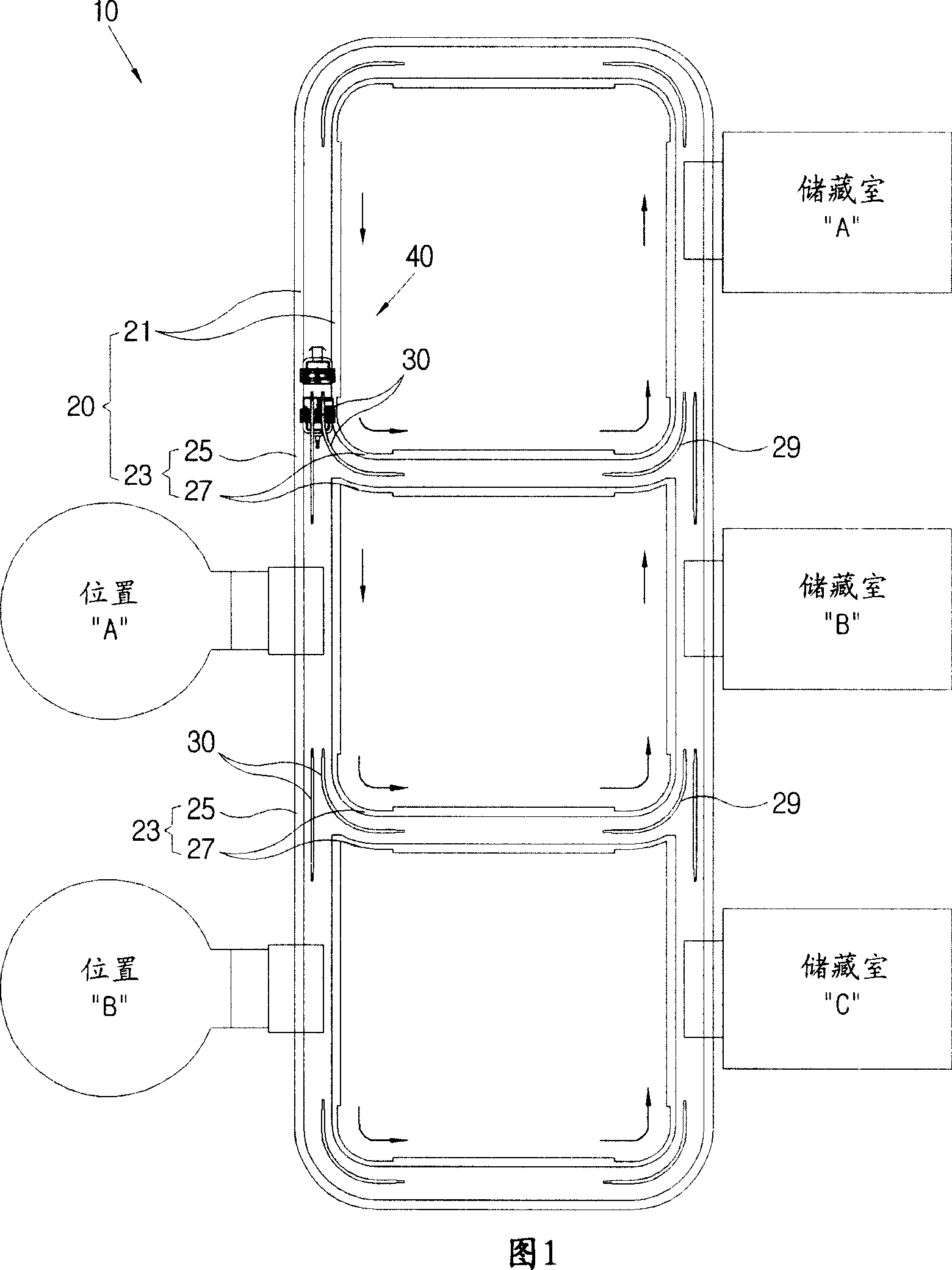

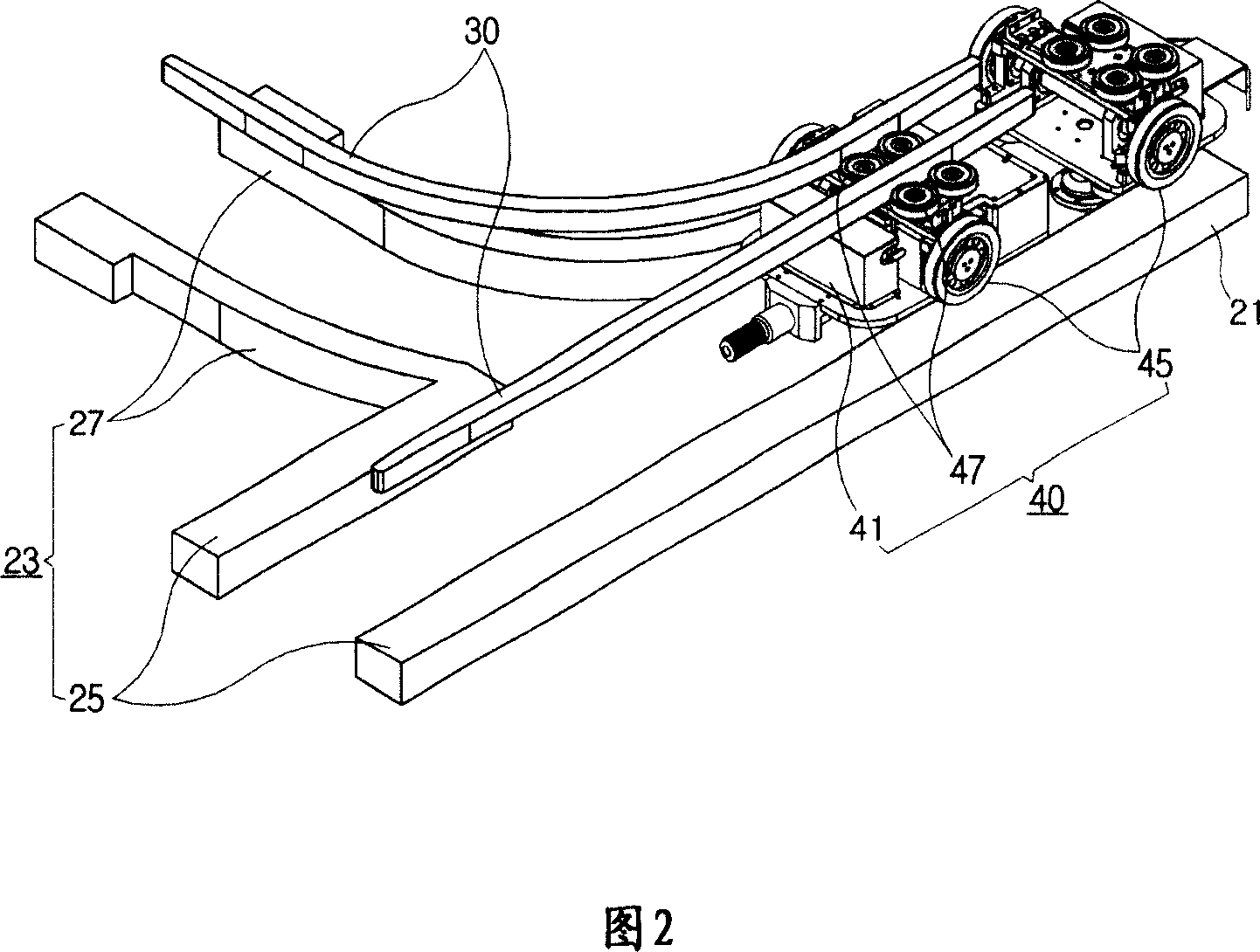

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Among various transfer devices, an overhead transfer device for transferring a reticle, a front opening unified pod (FOUP: Front Opening Unified Pod) and the like in a semiconductor production process will be exemplified.

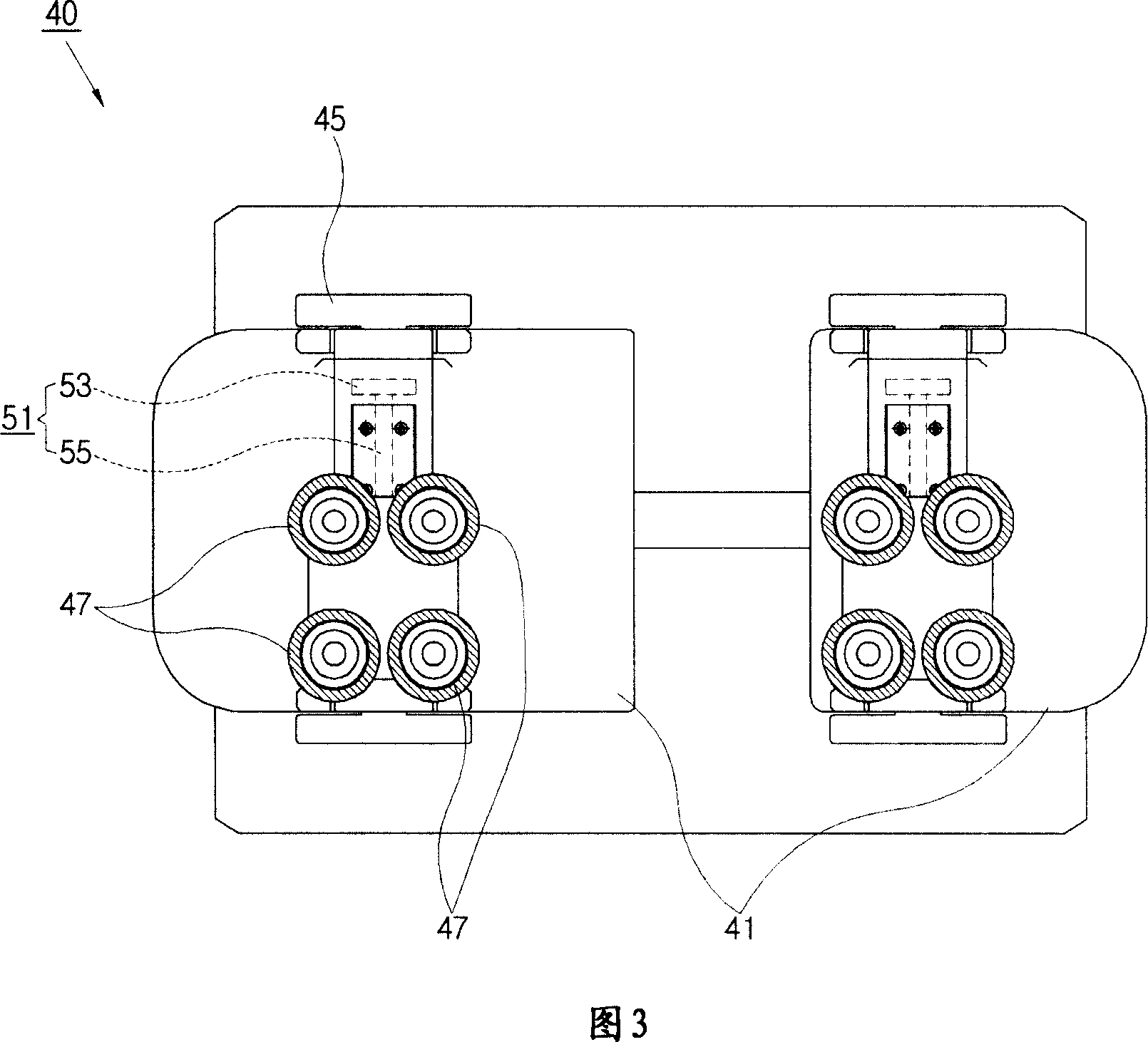

[0025] As shown in Fig. 2 to Fig. 4, conveying device 10 comprises: guide rail 20, and this guide rail 20 has the main track 21 that is formed by a pair of track parts and the branch track 23 that forms from main track 21 branch; The branch area of 23 is provided along the auxiliary guide rail 30 of the branch track 23; Side contact guides the guide wheel 47 of the transport vehicle main body 41 to change the running track. The conveying device 10 further includes a control unit 60 for controlling the driving and stopping of the guide wheel moving unit 51 , so that the transport vehicle body 41 can selectively run on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com