Closed observing environment for electronic microscope

An electron microscope, a closed technology, applied in the direction of circuits, discharge tubes, measuring devices, etc., can solve the problems of sample flow, liquid thickness is too thick, electron beam, uneven mixing of old and new samples, etc., to achieve the effect of easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the structure and characteristics of the present invention in detail, the following three preferred embodiments are given and described as follows in conjunction with the accompanying drawings:

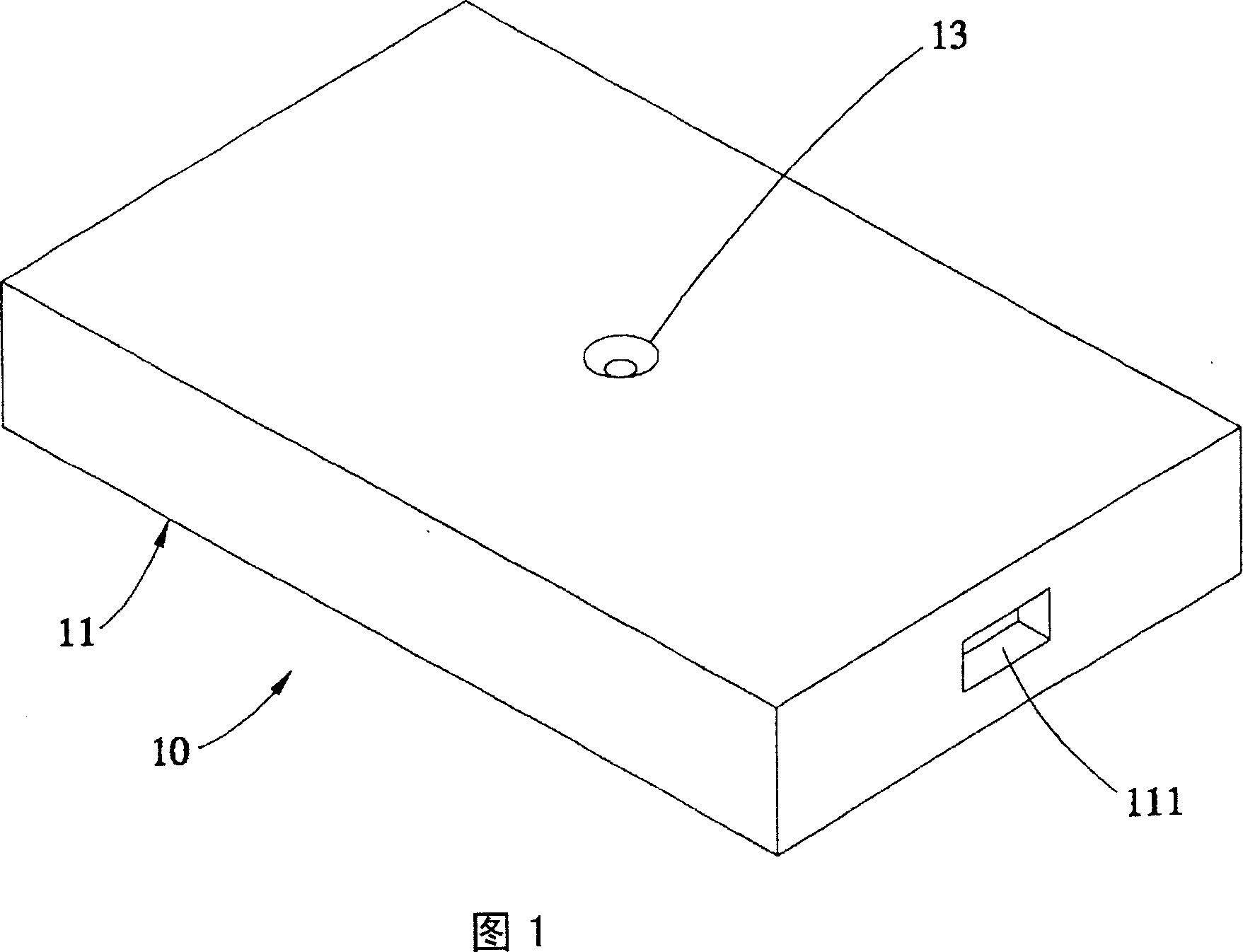

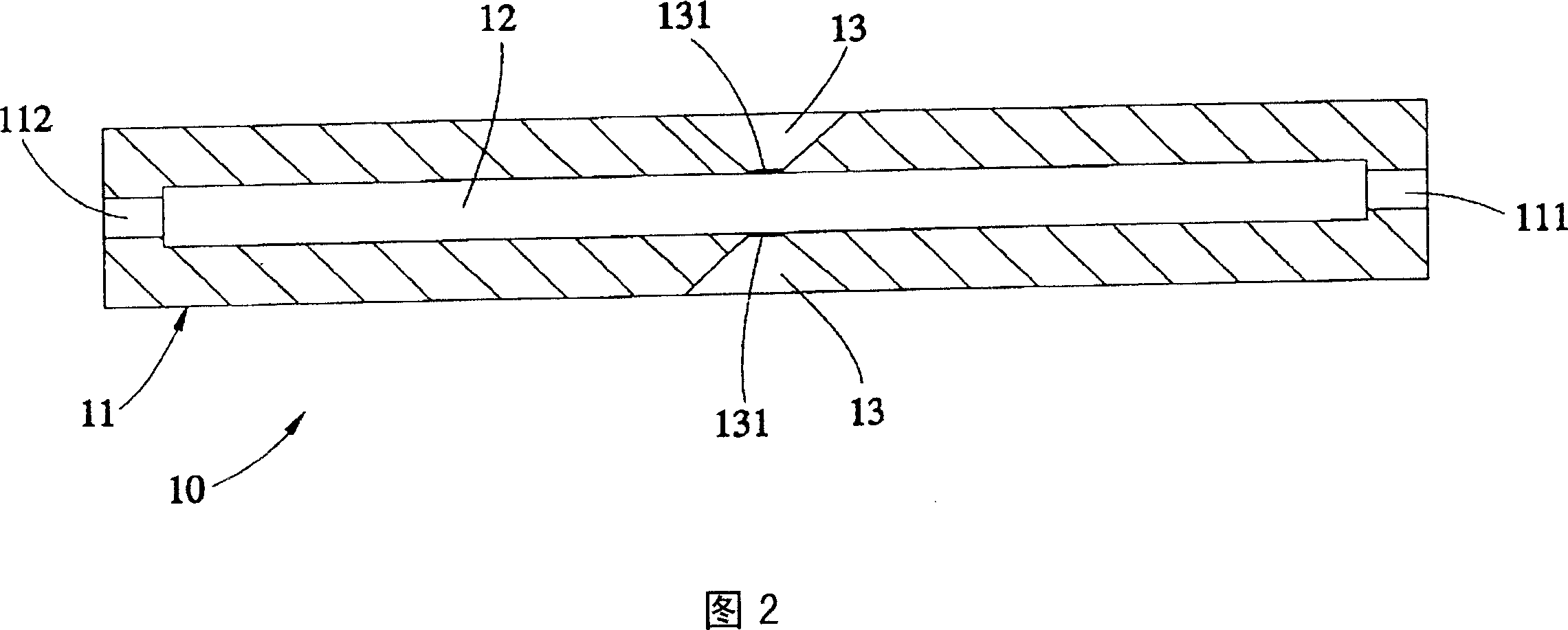

[0036] As shown in Figures 1 to 3 (A), a closed observation environment 10 for an electron microscope provided by the first preferred embodiment of the present invention mainly has:

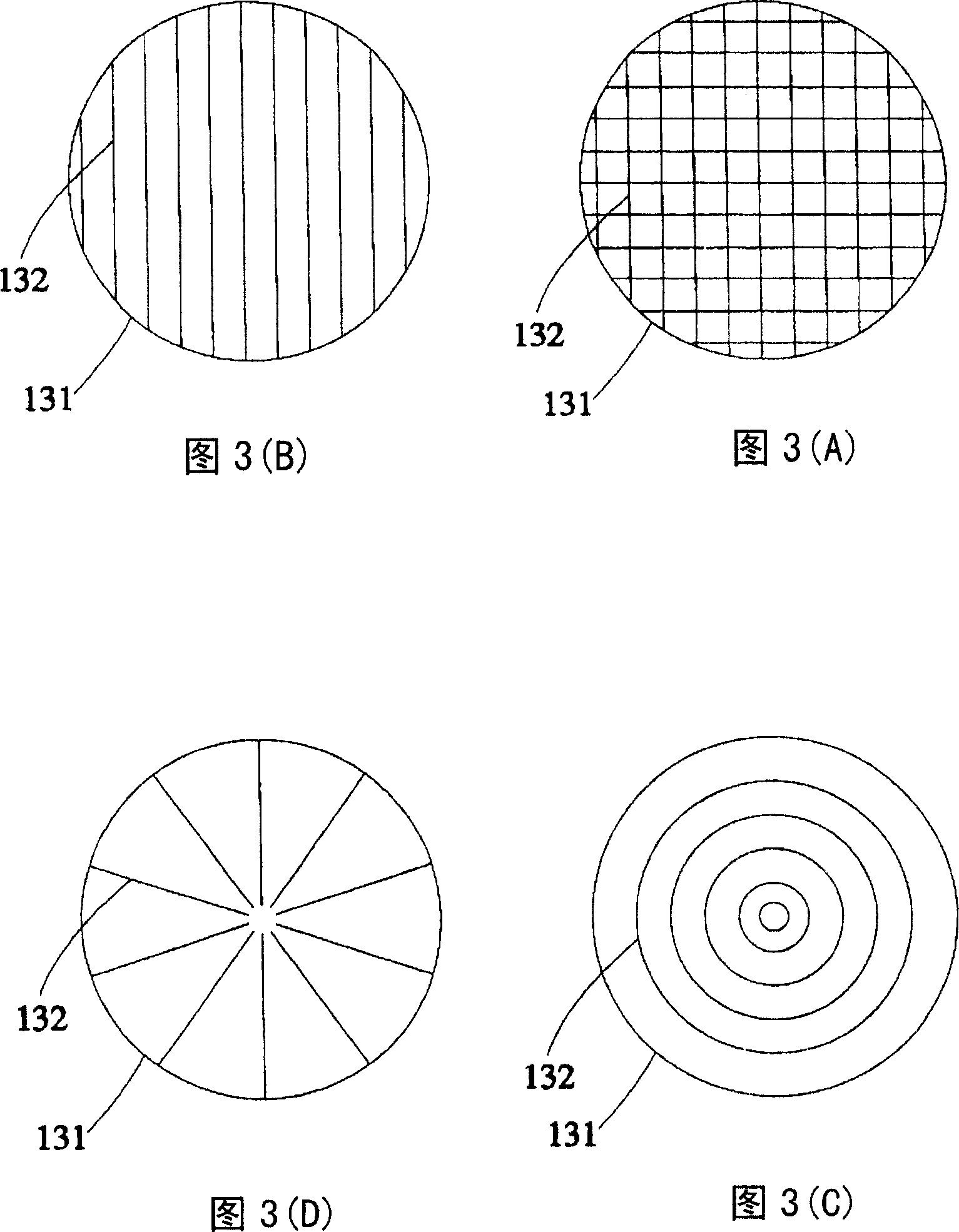

[0037] A casing 11 is integrally formed and has a chamber 12 inside. The top and bottom surfaces of the casing 11 each have at least one viewing hole 13 communicating with the chamber 12 and coaxial with each other; each viewing hole 13 is sealed Set a thin film 131, this thin film 131 can be amorphous carbon film or more flexible polymer film etc., its thickness is about between 100 to 20 nanometers (nm), this thin film 131 is positioned at this viewing hole 13 near this container One end of chamber 12. And in this embodiment, each of the films 131 is provided with a plurali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com