Transportation system cradle, intermediate product, assembly plant, and method for manufacturing assembly

A technology of transportation system and lifting system, applied in the field of lifting system, can solve problems such as unknown lifting system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

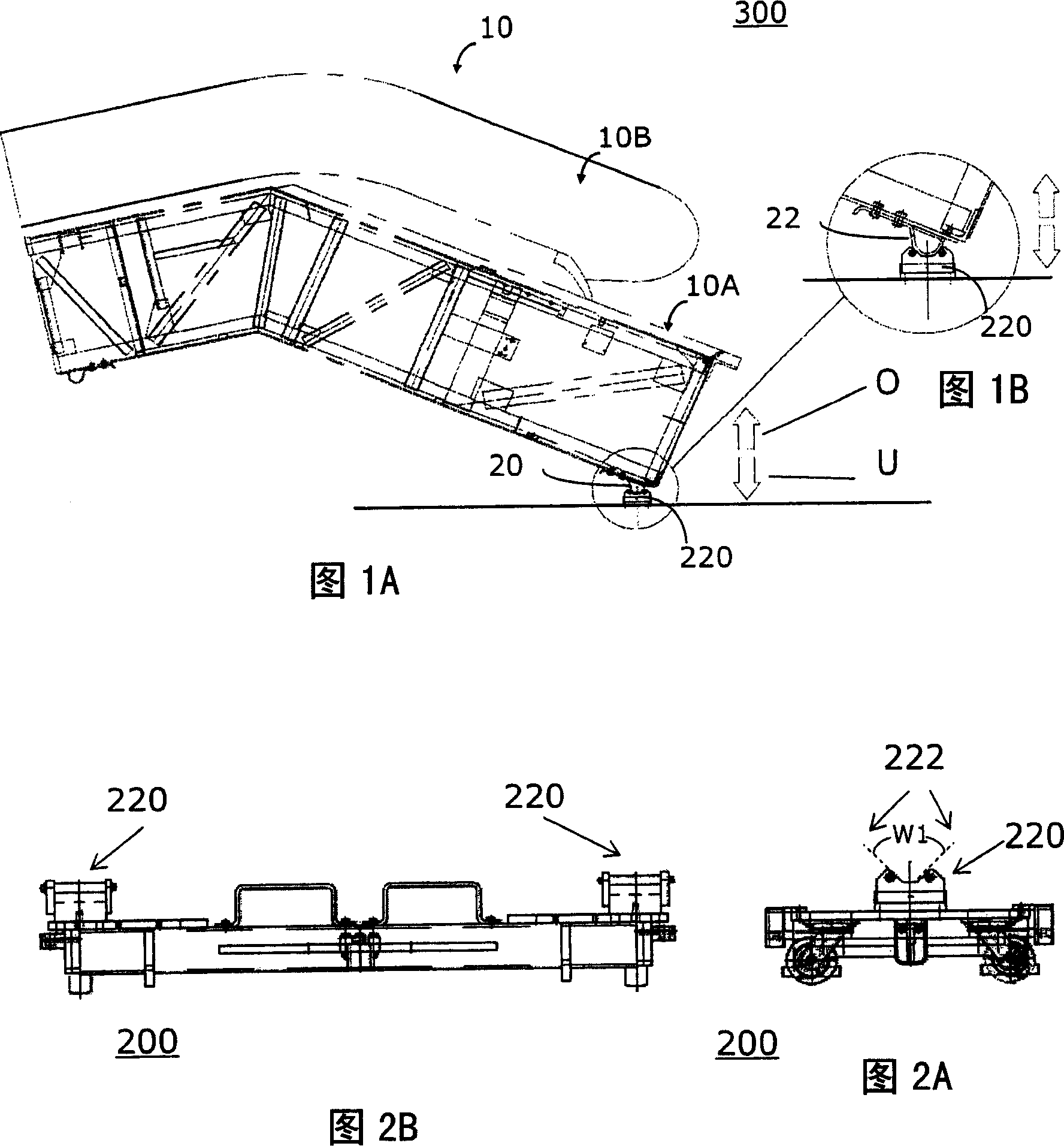

[0046] Figures 1A and 1B show a transportation system structure 10, the frame 10A of an unfinished escalator with a handrail 10B. The transport system structure 10 has a downward pointing foot or transport foot 20 which rests in a foot support 220 . The foot 20 and the foot support 200 basically form a lifting system 20 / 220 according to the invention. The foot 20 together with the connection area of the transport system structure 10 can be moved upwards and downwards in the directions of the arrows O and U relative to the foot support 220 .

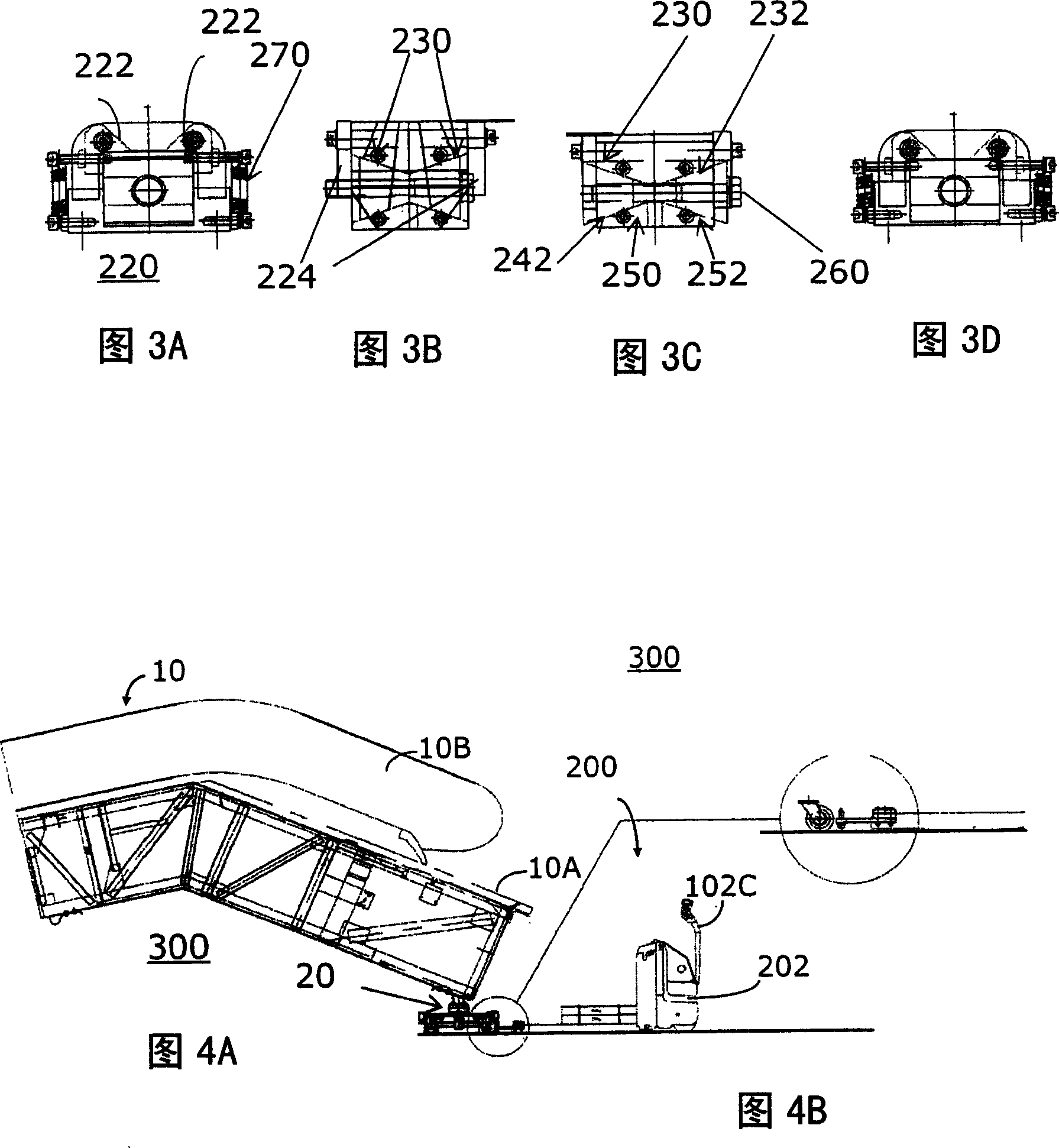

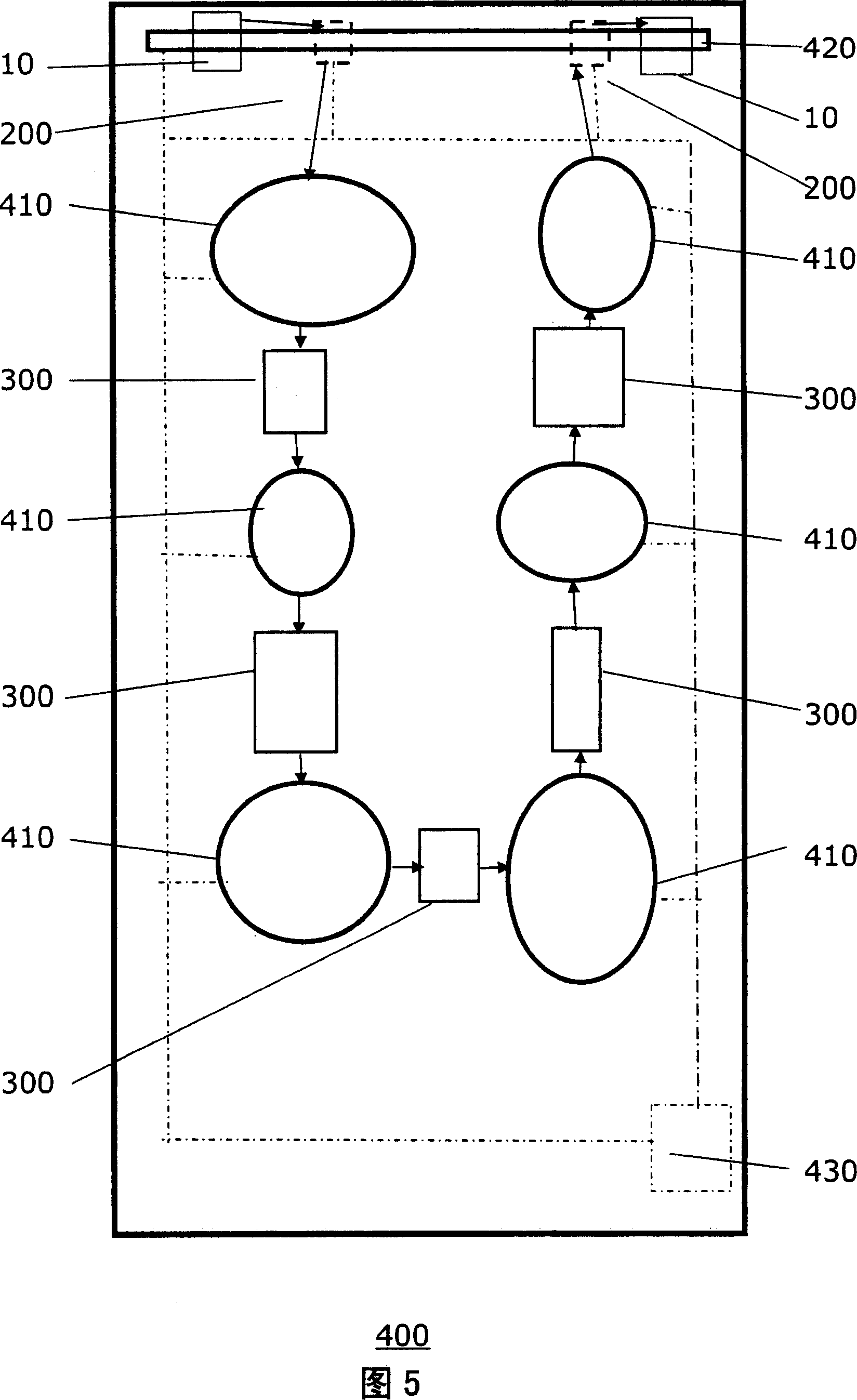

[0047] 2A and 2B show two substantially identical lifting systems 20, although the lifting systems 20 / 220 shown in FIGS. / 220, the two lifting systems 20 / 220 are arranged as a pair in FIG. 2B left and right on the transport system support unit or the mobile support unit of the transport system support 200.

[0048] The foot 20 shown only in FIGS. 1A and 1B is made wedge-shaped or circular and has two foot surfaces 22 facing each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com