Telescopic vacuum cleaner suction hose

A vacuum cleaner, retractable technology, applied in the direction of vacuum cleaners, suction hoses, cleaning equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

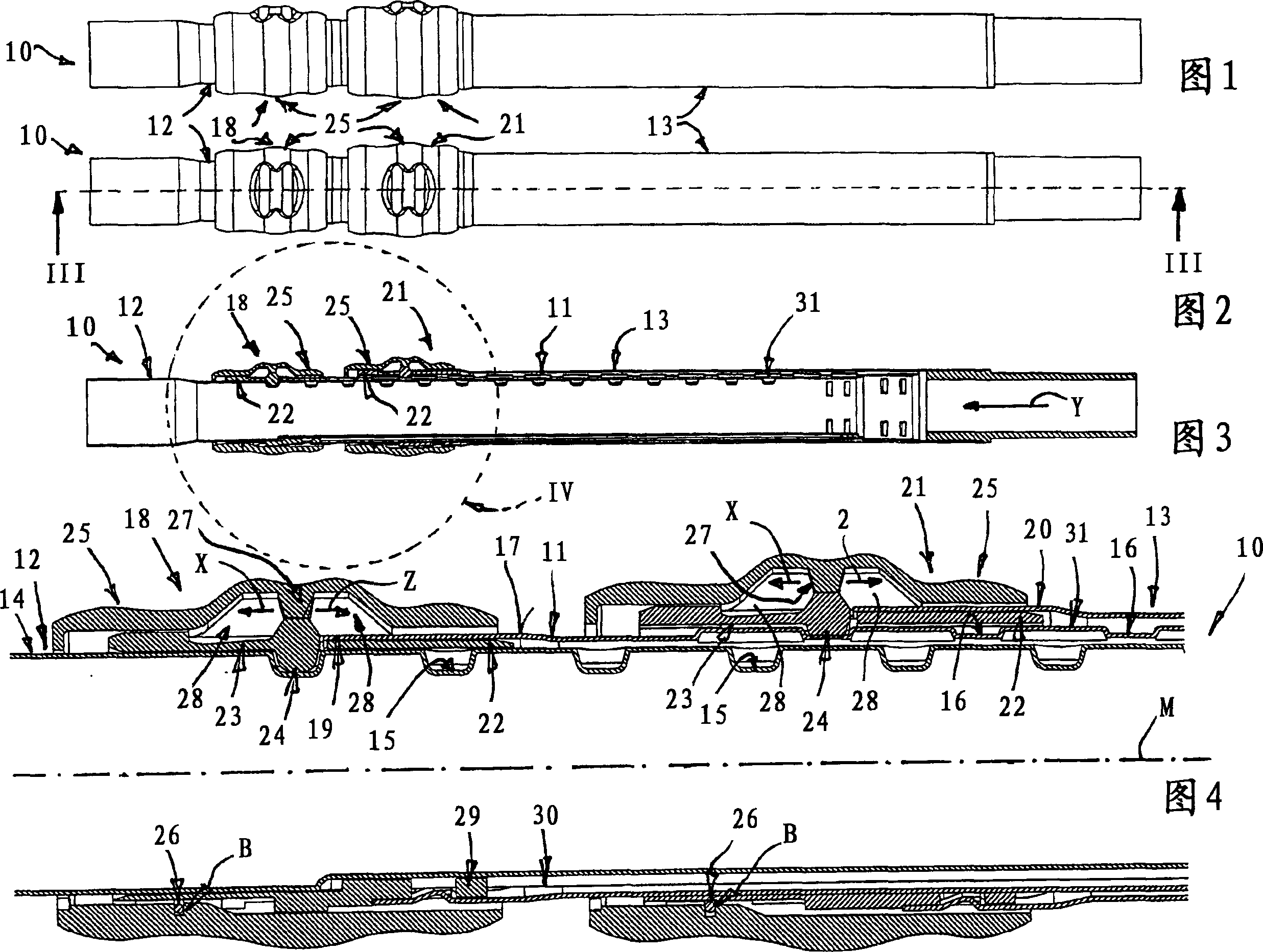

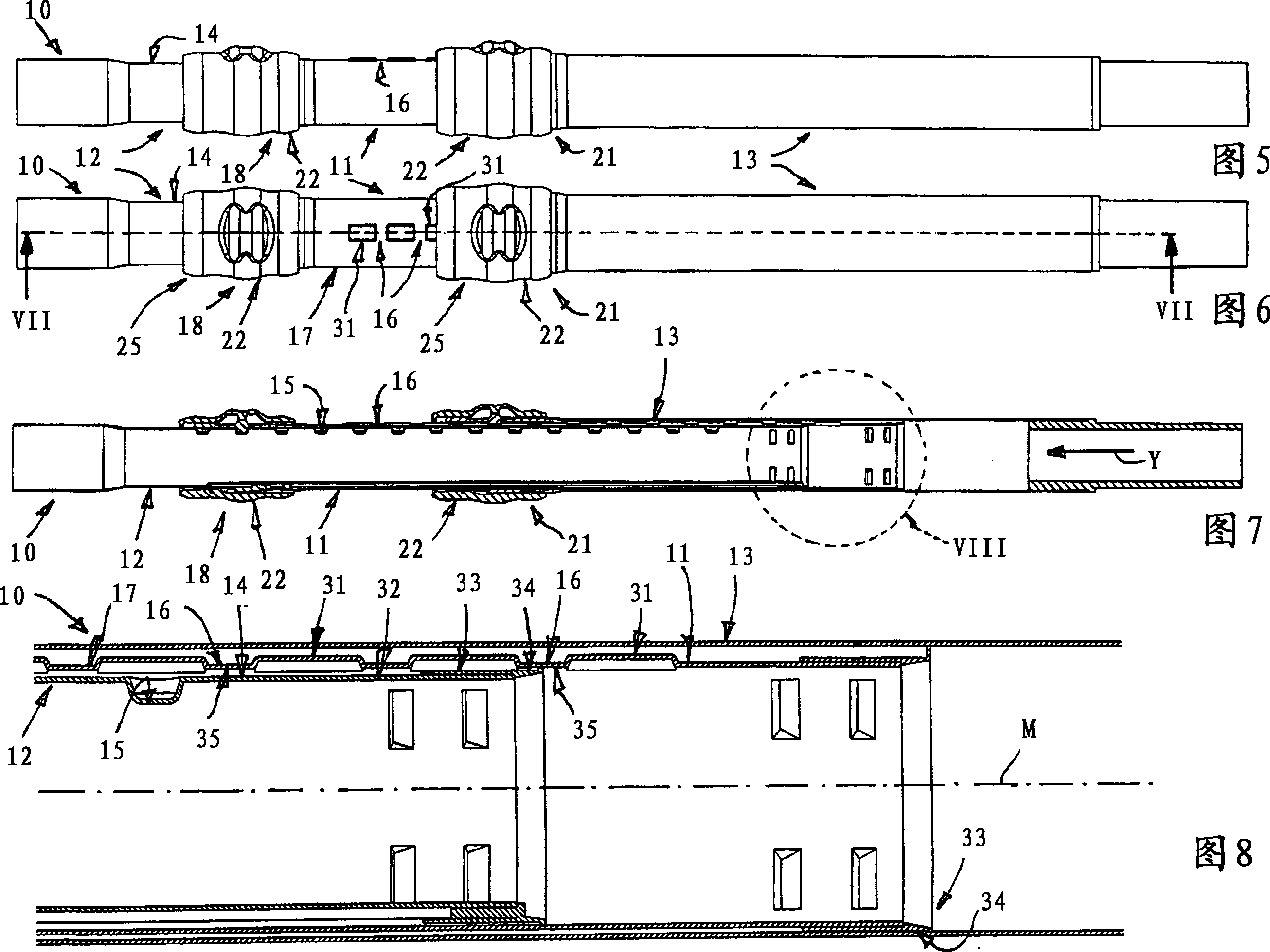

[0021] A retractable vacuum cleaner suction pipe is always indicated by reference numeral 10 in the figures.

[0022] The telescoping vacuum cleaner suction pipe 10 has an outer pipe 11 , an inner pipe 12 axially displaceable in the outer pipe, and finally an additional outer pipe 13 telescopically overlapping the outer pipe 11 .

[0023] The inner tube 12 has a plurality of buckling grooves 15 protruding away from the outer surface 14 of the inner tube toward the central axis M of the tube. On the contrary, the outer tube has a plurality of second snap-in grooves 16 which open outward away from the outer surface 17 of the outer tube and the central axis M of the tube. Therefore, the bottom surface of each second locking groove 16 is consistent with the outer surface 17 of the outer tube and thus constitutes an undeformed tube wall region 35 .

[0024] The additional outer tube 13 of the telescopic overlapping outer tube 11 has no snap-in grooves and is smooth overall. All t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap