Dynamic vibration absorber and optical disk device

A technology of optical disc device and shock absorber, which is applied in the direction of poor vibration/sound insulation/absorption, head configuration/installation, flat record carrier equipment, etc., can solve problems such as the inability to use dynamic shock absorbers, and achieve the effect of eliminating design restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

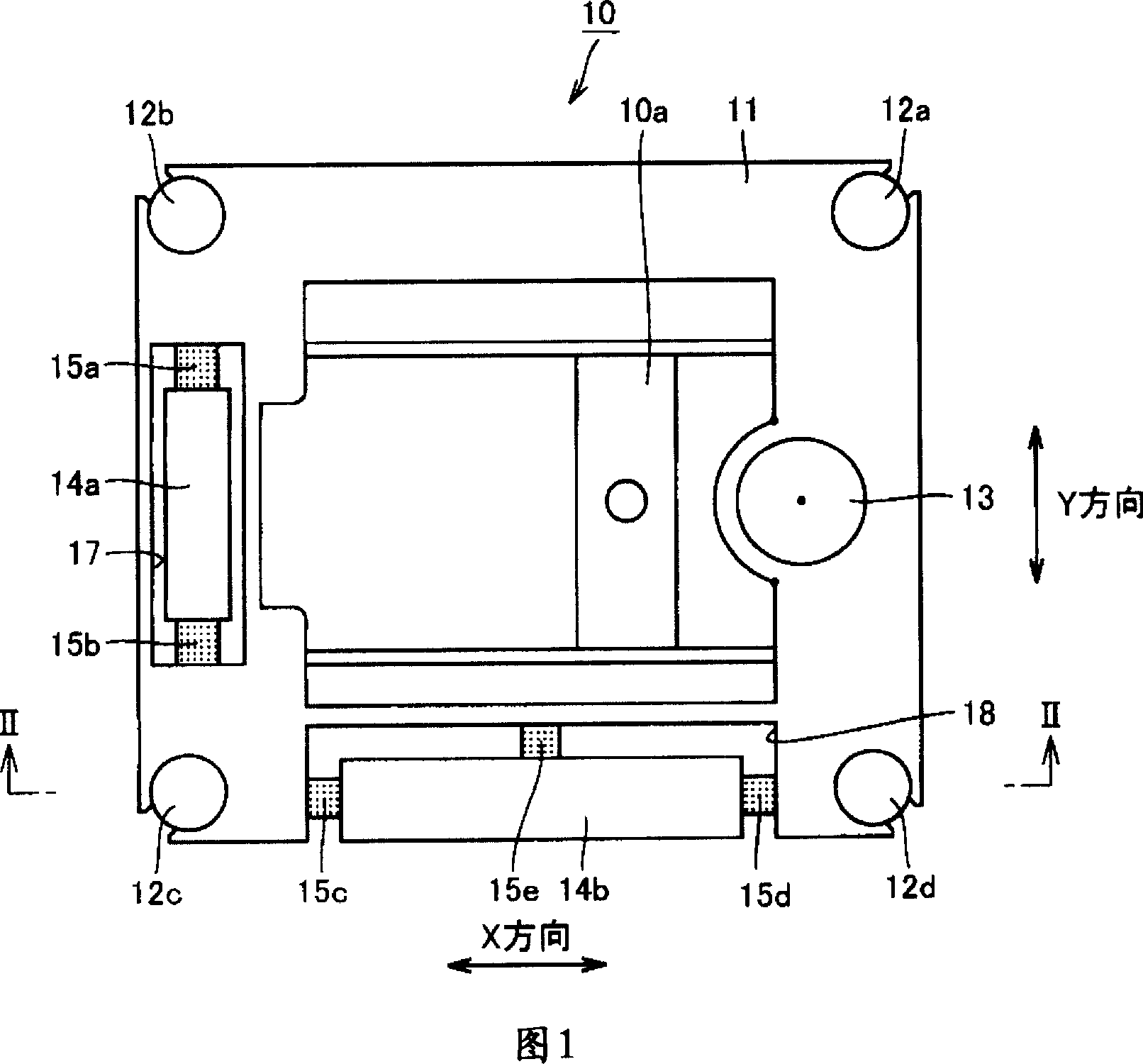

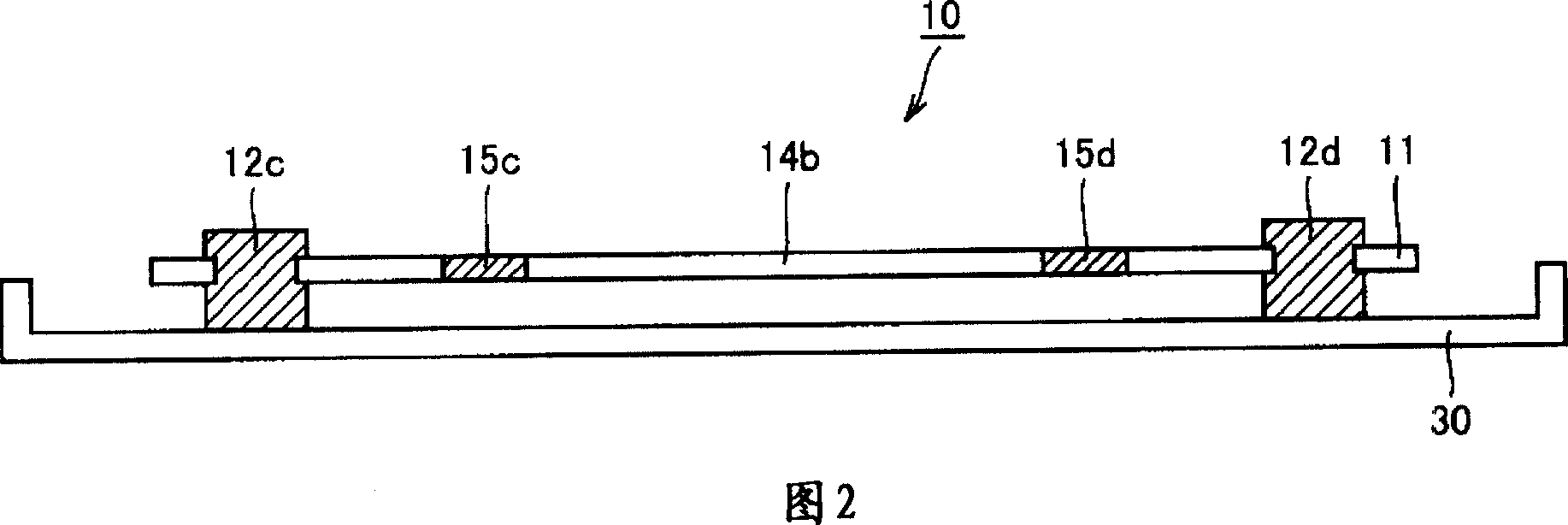

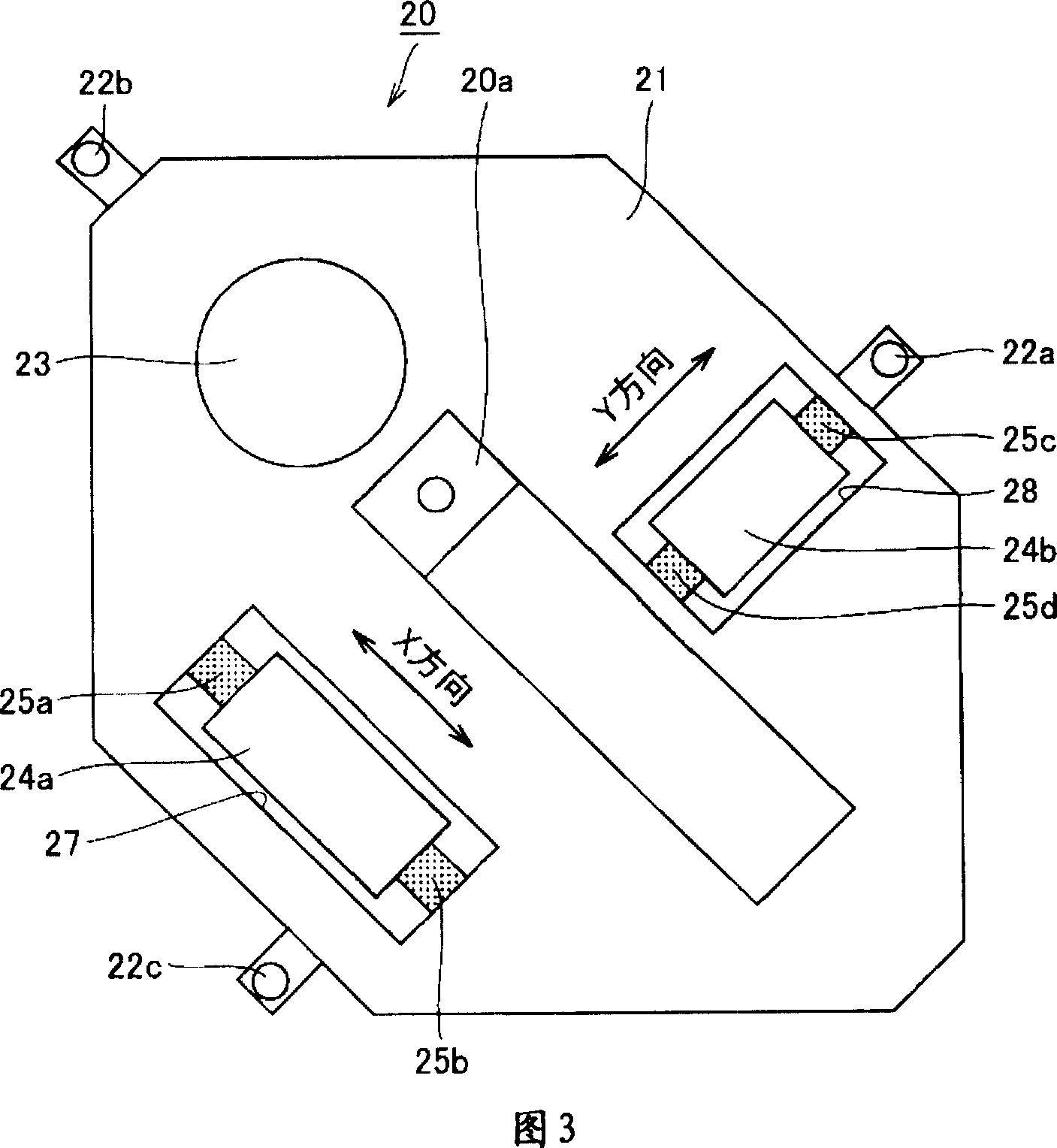

[0025] Embodiments of the present invention will be described below with reference to the drawings. 1 is a plan view showing a dynamic shock absorber according to an embodiment of the present invention and an optical disc device using the same, and FIG. 2 is a cross-sectional view of a portion indicated by II-II in FIG. 1 . In addition, in FIG. 2, hatching is not drawn with respect to a dynamic shock absorber. Also, in this embodiment, the dynamic shock absorber based on the present invention is applied to a half-height optical disc device. In addition, the optical disc device here refers to a device that drives an optical drive such as CD, CD-ROM, DVD, DVD-ROM, or an optical disc such as a magneto-optical disc or a large-capacity floppy disc.

[0026] Referring to FIG. 1 and FIG. 2, the optical disc device 10 includes a rectangular planar base frame 11 and second elastic bodies 12a-12d provided at the four corners of the base frame 11, and through the second elastic bodies 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com