Shock wave process and apparatus for synthesizing cubic silicon nitride material

A technology of cubic silicon nitride and synthesis method, which is applied in the direction of nitrogen compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of complicated laboratory operation, inability to meet industrial application, harsh conditions, etc. The effect of industrial application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

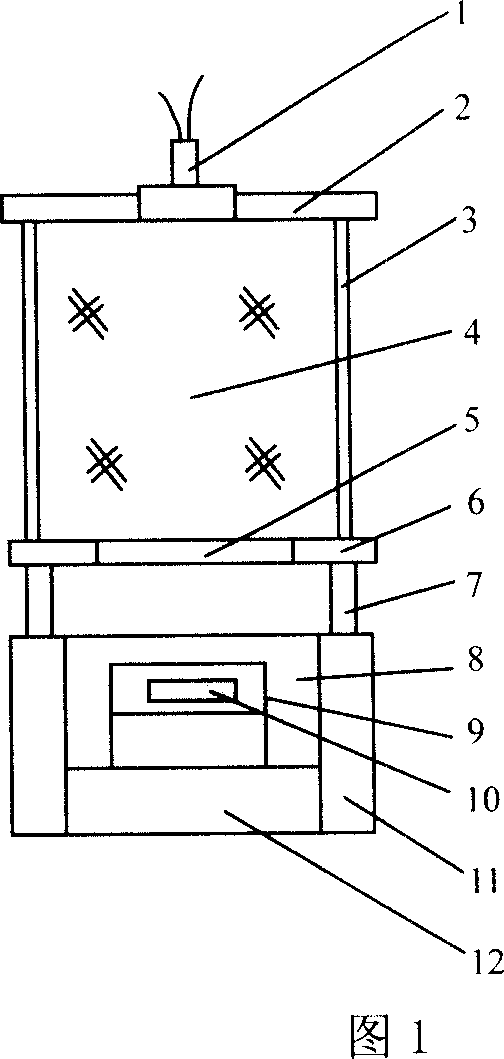

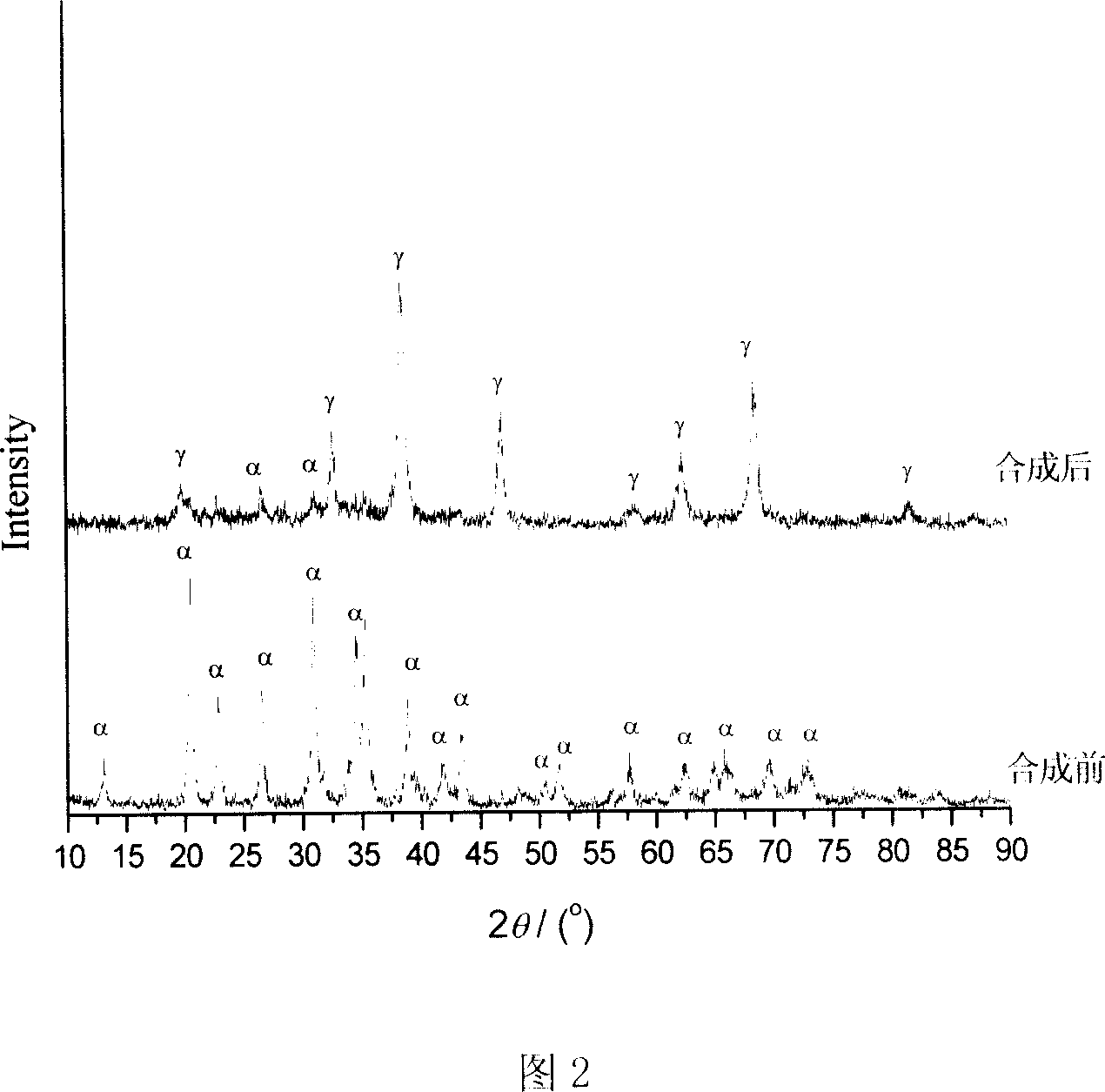

[0041] Weigh 2.3 grams of α-phase silicon nitride powder with a particle size of 1 μm to 10 μm as the initial raw material, then weigh 9.2 grams of copper powder with a particle size of 200 mesh to 300 mesh and mix it evenly with the α-phase silicon nitride raw material, of which copper powder is an additive , mainly plays the role of cooling, and its mass percentage is 90%, and the α-phase silicon nitride powder is used as raw material, and its mass percentage is 10%. Put the mixed raw materials in an agate mortar and grind for half an hour, then pour the ground mixed material into the copper raw material chamber, and then use a press to compact the mixed raw materials in the raw material chamber with a pressure of 5Mpa. Put the raw material box 9 in the recovery device part, then assemble the detonation loading device part at the upper end of the recovery device part, put the copper flyer 5 with a diameter of 60 mm and a thickness of 1 mm at the bottom of the cartridge 3, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com