Planar inductor using liquid metal mems technology

An inductive, liquid technology used in inductors, coreless inductors, fixed inductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The best mode for carrying out the present invention is described in detail below. This description is intended to illustrate the invention and should not be considered as limiting the invention.

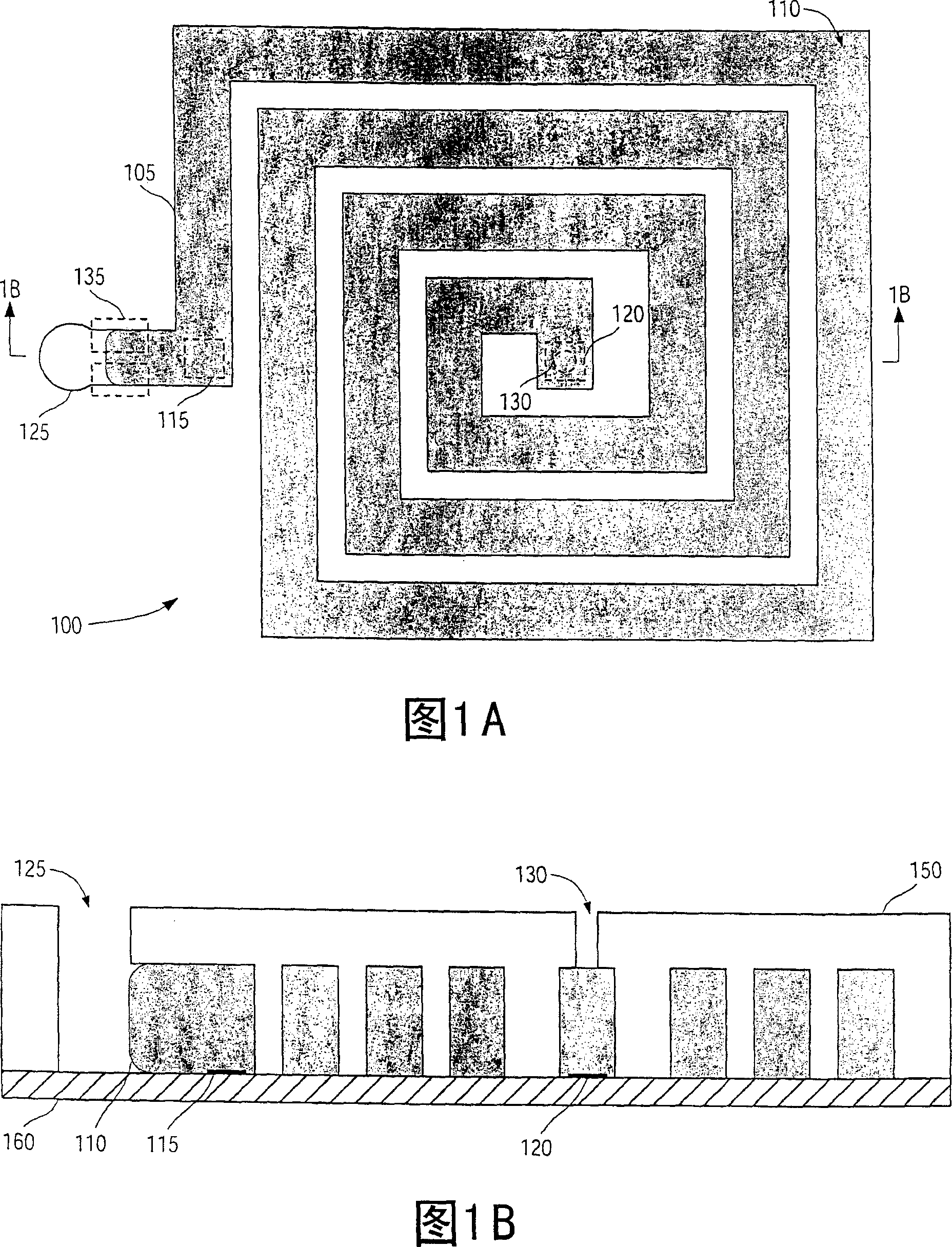

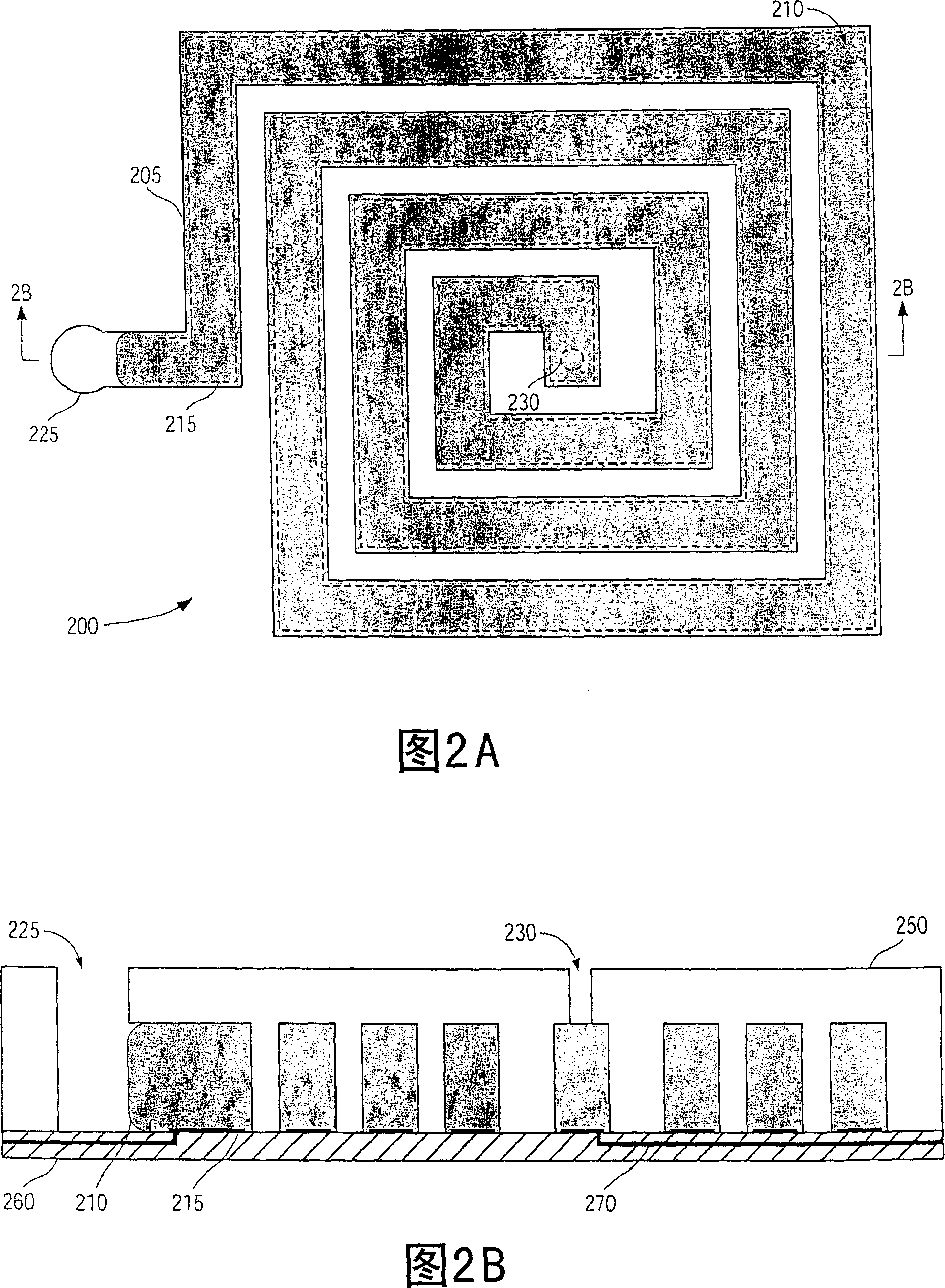

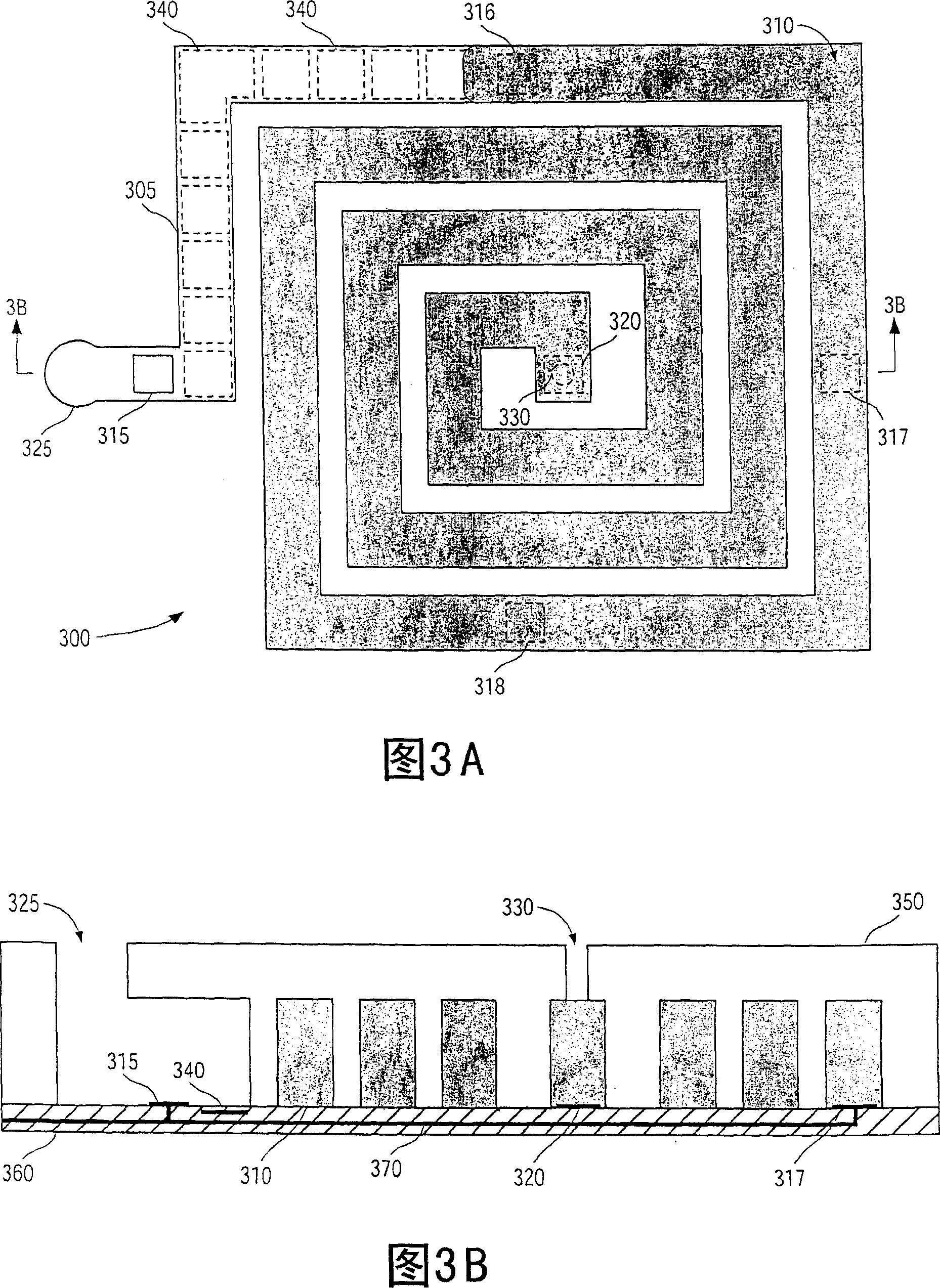

[0011] In this application, various MEMS device fabrication processes and techniques known to those skilled in the art will be mentioned. Many of these processes and techniques can be borrowed from semiconductor device fabrication techniques, such as photolithography, thin film deposition and growth techniques, etching processes, etc., while others have been developed and / or modified specifically for MEMS applications. Furthermore, the devices and techniques now described focus on the use of liquid metals in inductors. Examples of suitable liquid metals include mercury, gallium alloys and indium alloys (eg Galinstan or GaInSn). Other examples of suitable liquid metals with acceptable conductivity, stability and surface tension properties are known to those skilled in the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com