Three-point-linked variable spherical curvature measuring instrument and method therefor

A curvature measurement and linkage technology, which is applied in the direction of instruments, measuring devices, mechanical measuring devices, etc., can solve the problems of reducing measurement accuracy, achieve high positioning accuracy, simple and novel structure, and improve measurement accuracy and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

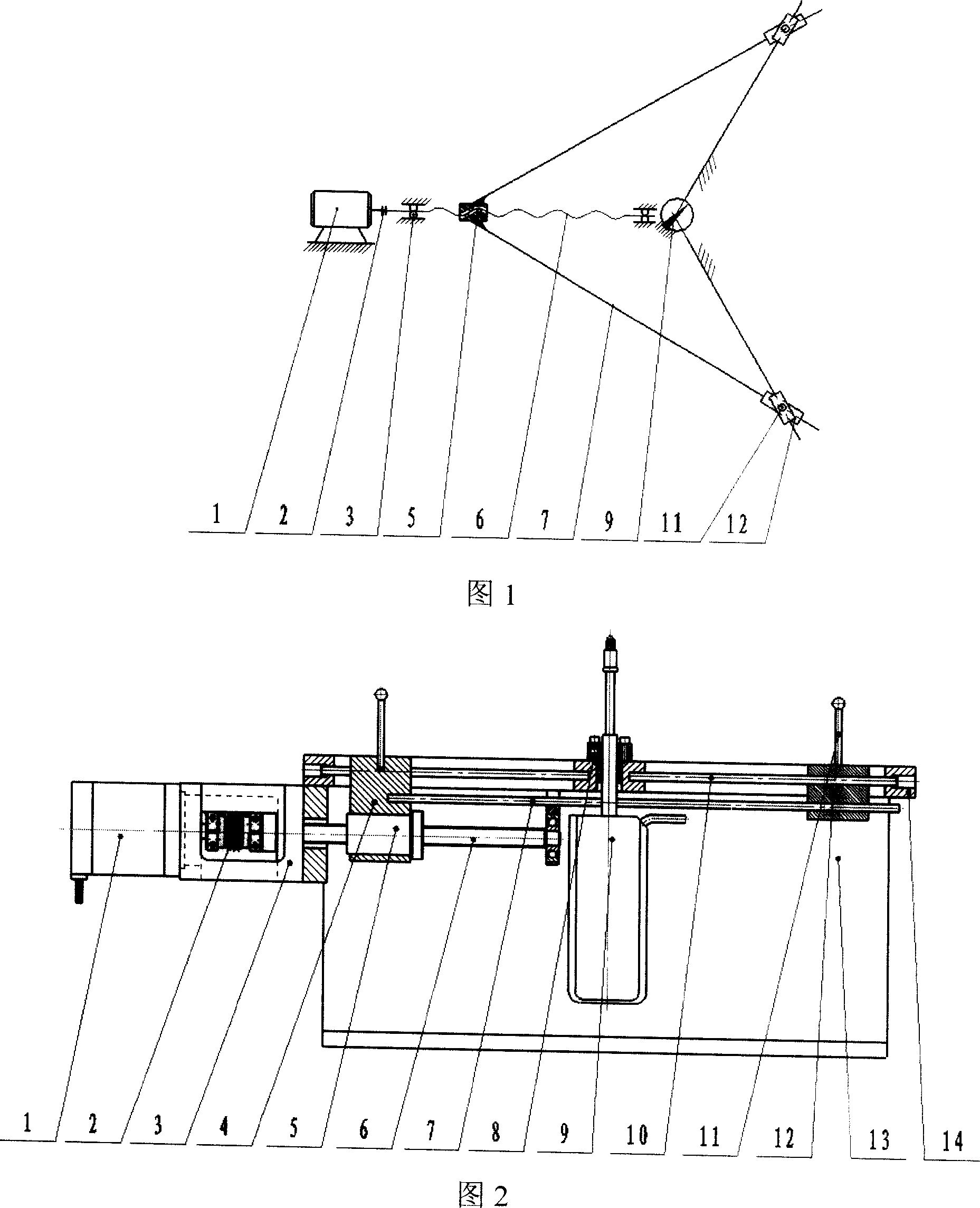

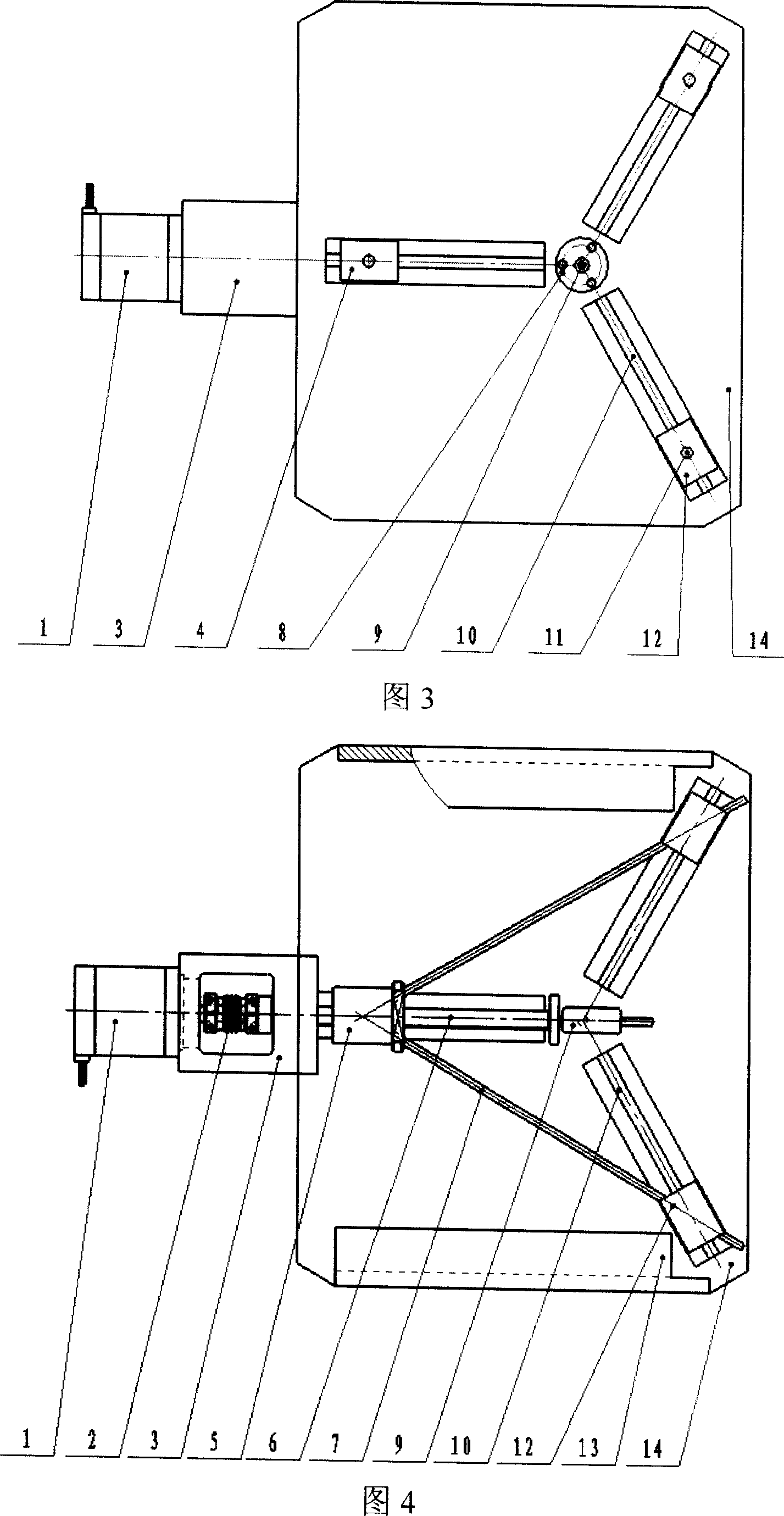

[0036] The measuring instrument of the present invention will be described in further detail below in conjunction with the accompanying drawings.

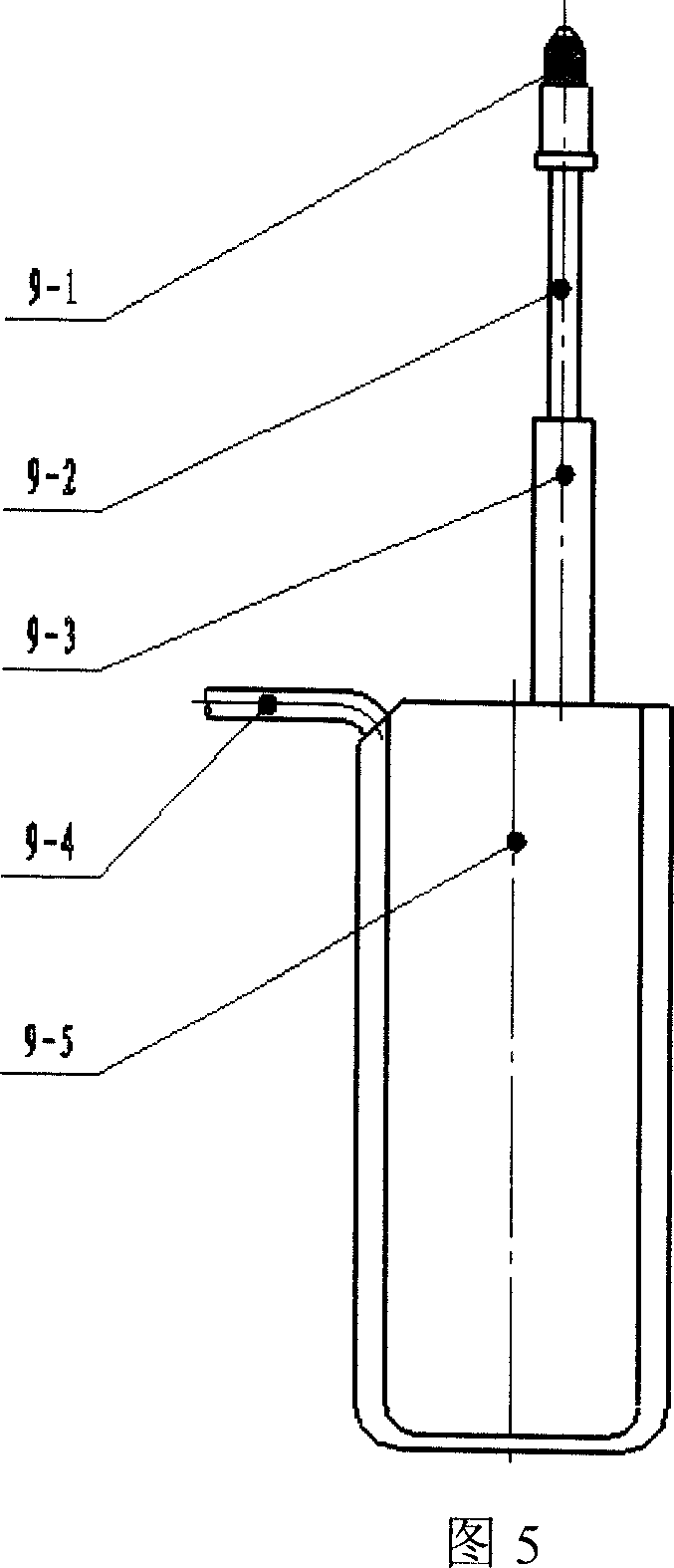

[0037] First refer to Figure 1, a three-point linkage variable diameter spherical curvature measuring instrument, which mainly includes a single-chip microcomputer and a display (not shown in the figure), a length micrometer 9, a stepping motor 1, a ball screw 6, a sliding rod 7. The guide rod 10, the active sliding block 4, the passive sliding block 12, the supporting rod 11, the working platform 14 and the base 13 are composed.

[0038] The single-chip microcomputer has two lines: a data line is connected to the stepper motor 1, the single-chip microcomputer outputs the rotation control signal (the number of steps, direction and speed) of the stepper motor 1 through the data line; the other data line is connected to the length micrometer 9 for receiving The measurement data signal of the length micrometer 9. The single-chip microcomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com