Conveyor oven

A conveying device and gas technology, applied in food ovens, household stoves/stoves, kitchen utensils, etc., can solve the problems of unsuitable conveying ovens, no space for enlargement, etc., and achieve the effect of reducing cooking time and increasing rotation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

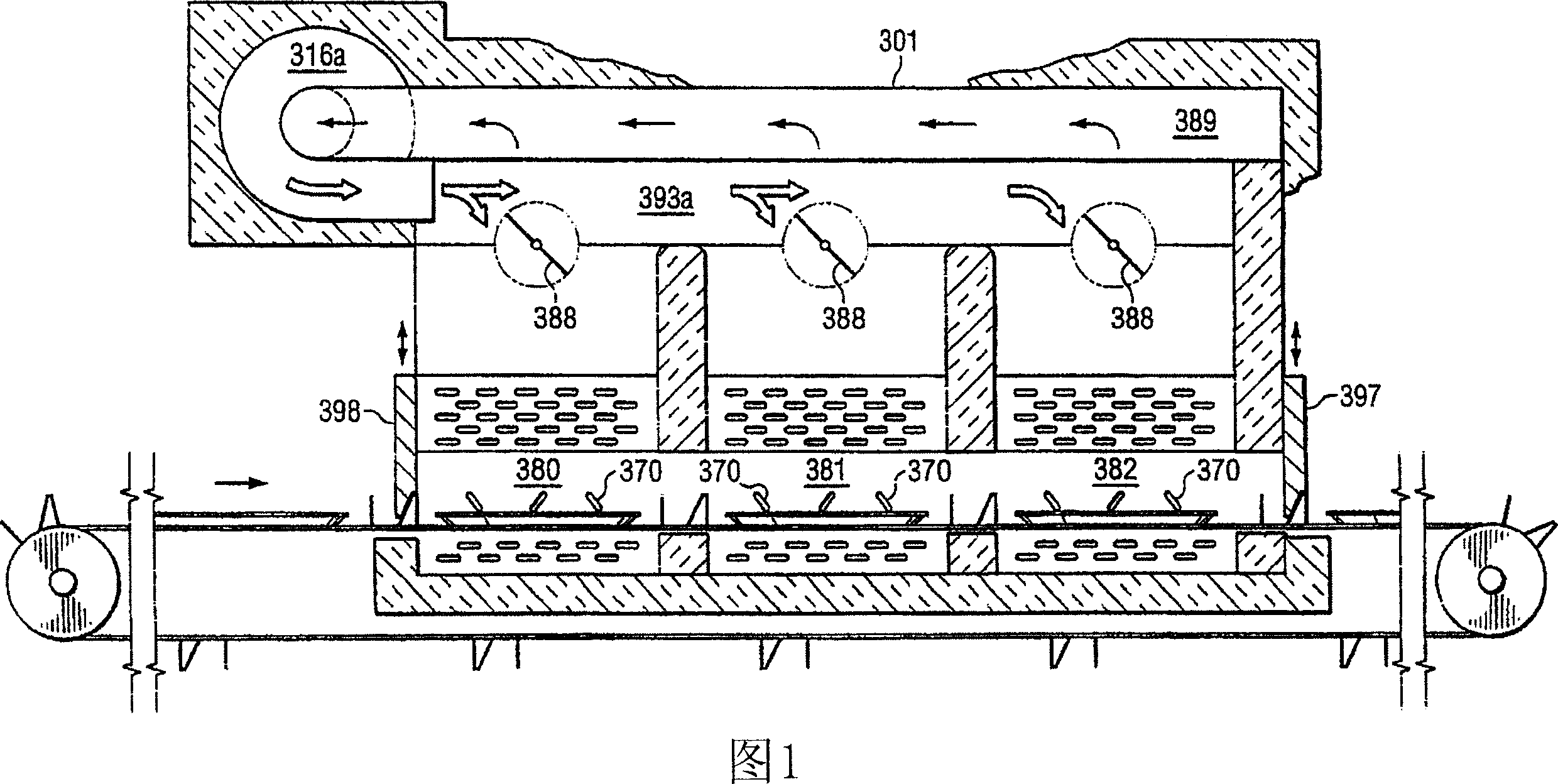

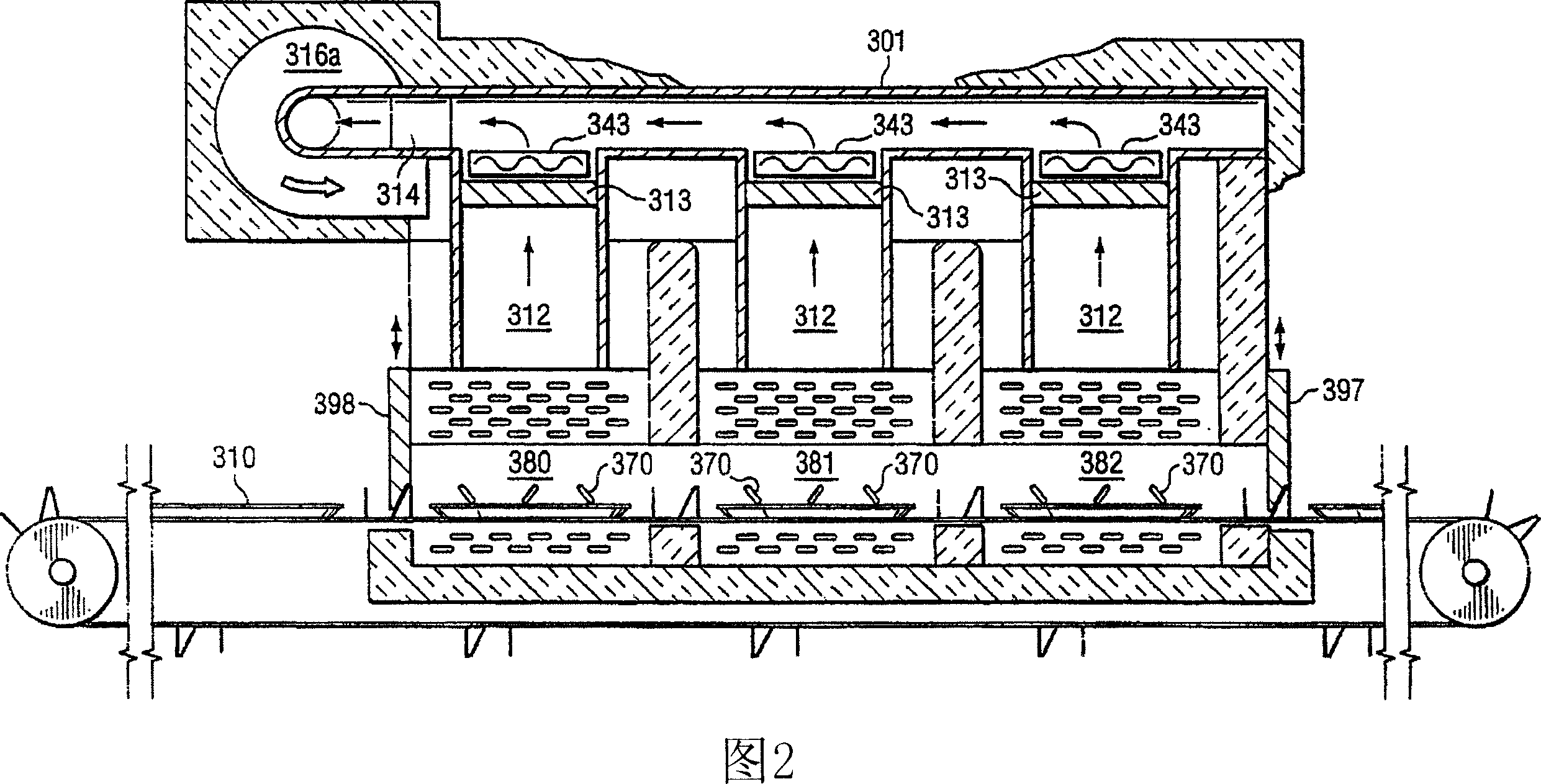

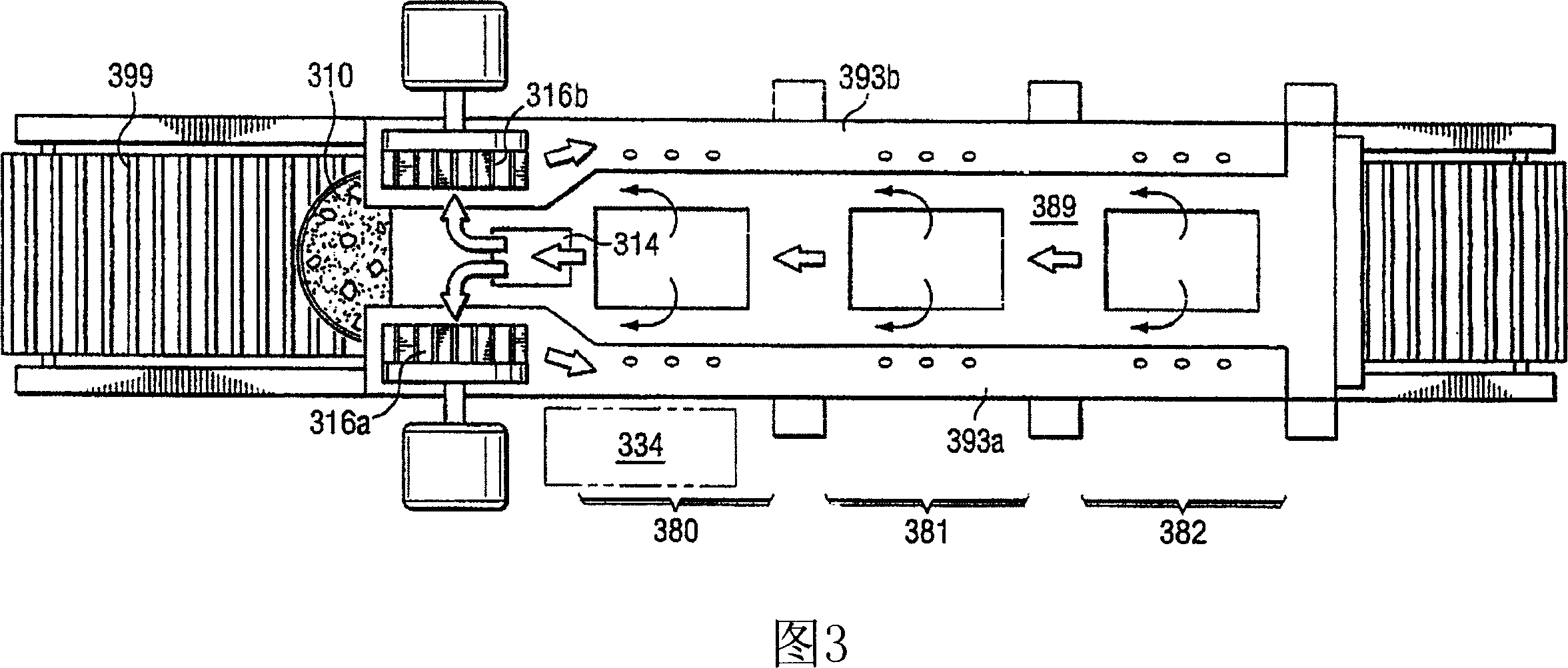

[0032] The oven of the exemplary embodiment is shown as a quick cook commercial conveyor cooking appliance with 3 cooking zones, where although each cooking zone is not necessarily identical, and in fact in some cases it may be desirable for one or more cooking zones to be fabricated as different, but each cooking zone is shown manufactured in the same way. The conveyor furnace of the present invention can be installed in other embodiments because it can be made larger or smaller in size. The term "variable size" here means that additional larger or smaller models can be formed, and that each embodiment or variation can have different size characteristics and use different voltages; various forms of resistance heating means, or Use a heat source such as natural gas, propane, or other heating means to heat the gas.

[0033] As used herein, the terms "magnetron", "magnetron" and "tube" have the same meaning; the terms "slot", "slots" and "antenna" have the same meaning: the ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com