Device to apply rubber tape

A technology of rubber belts and conveyor belts, applied in the field of devices for applying rubber belts, can solve problems such as easy rupture of thin rubber belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

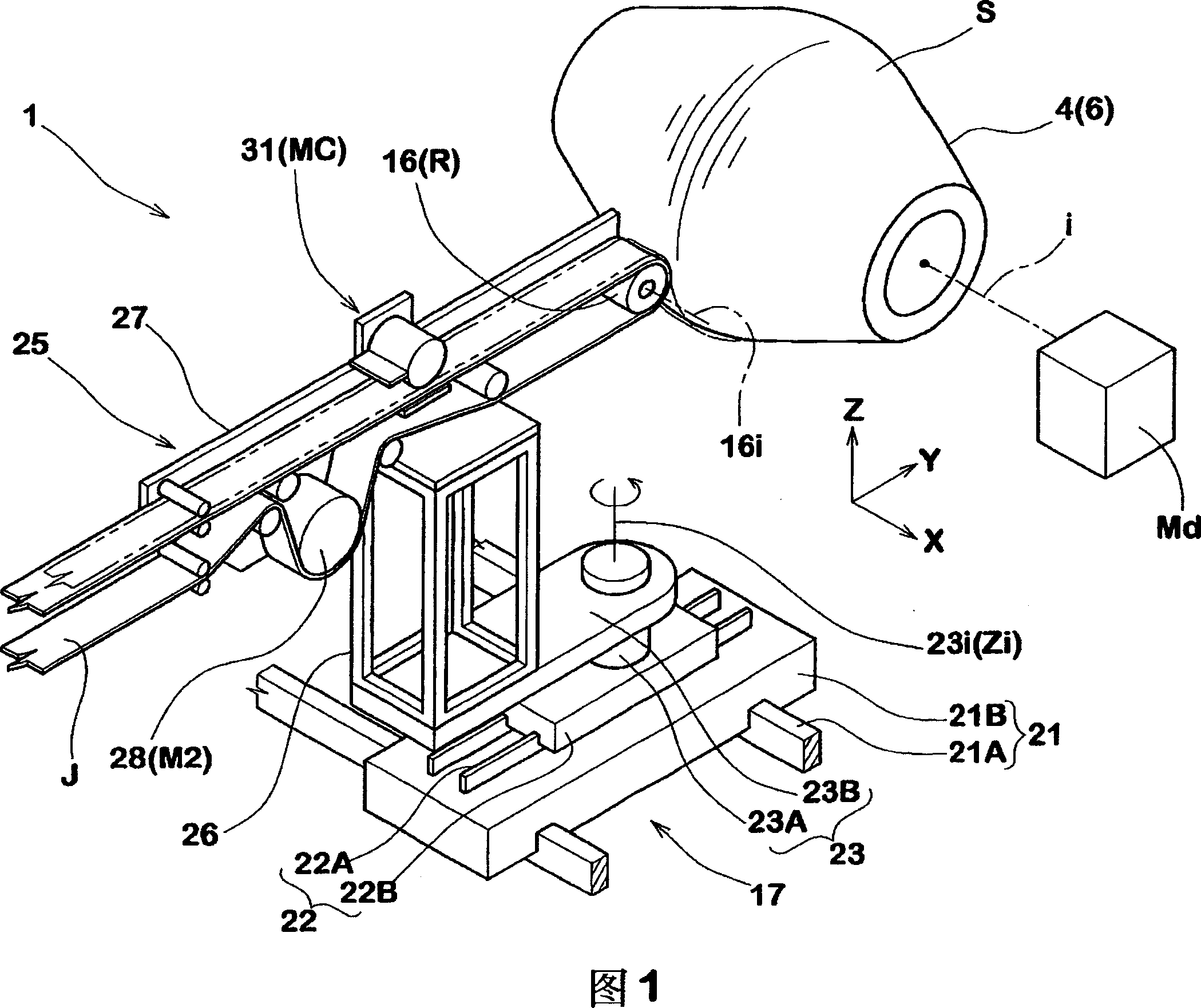

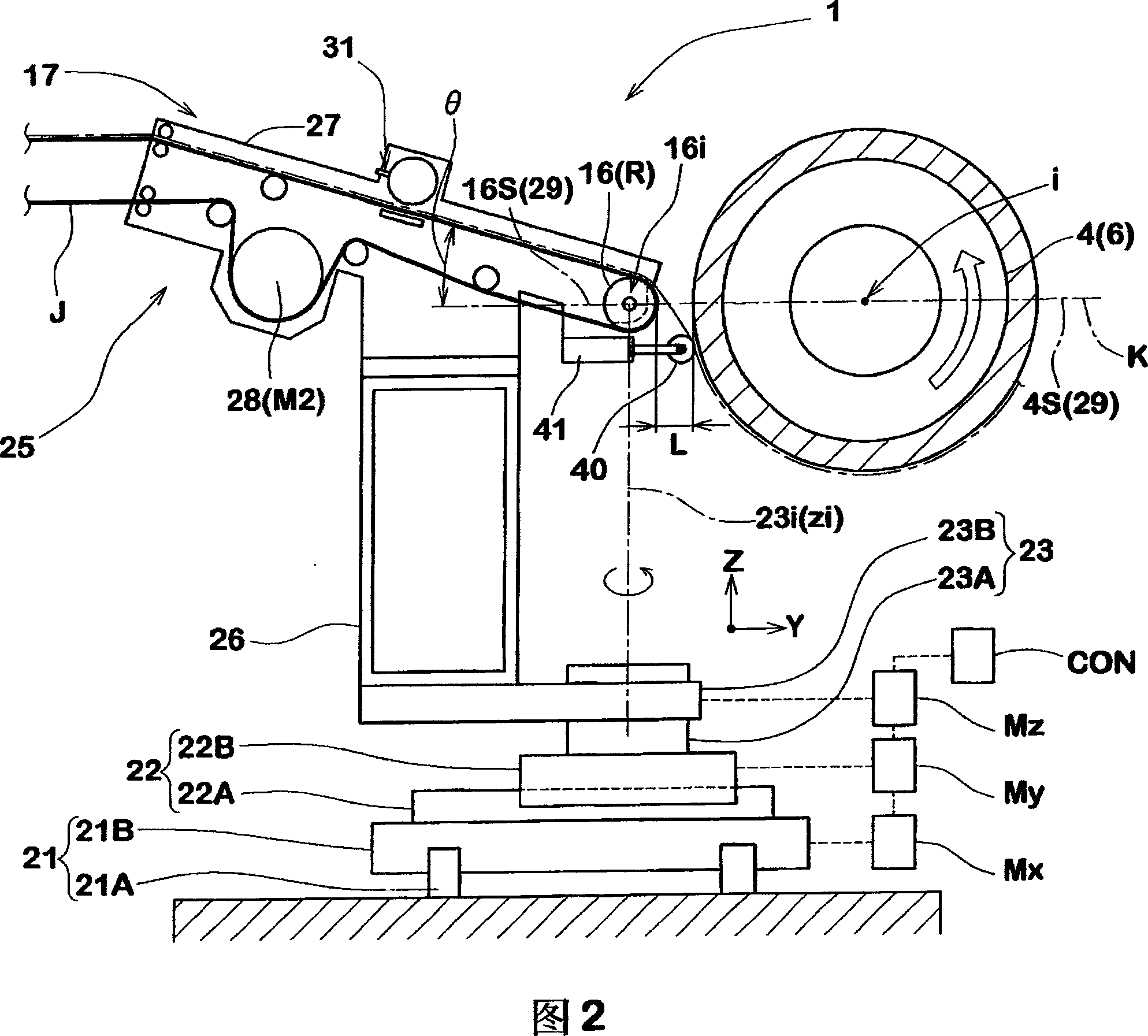

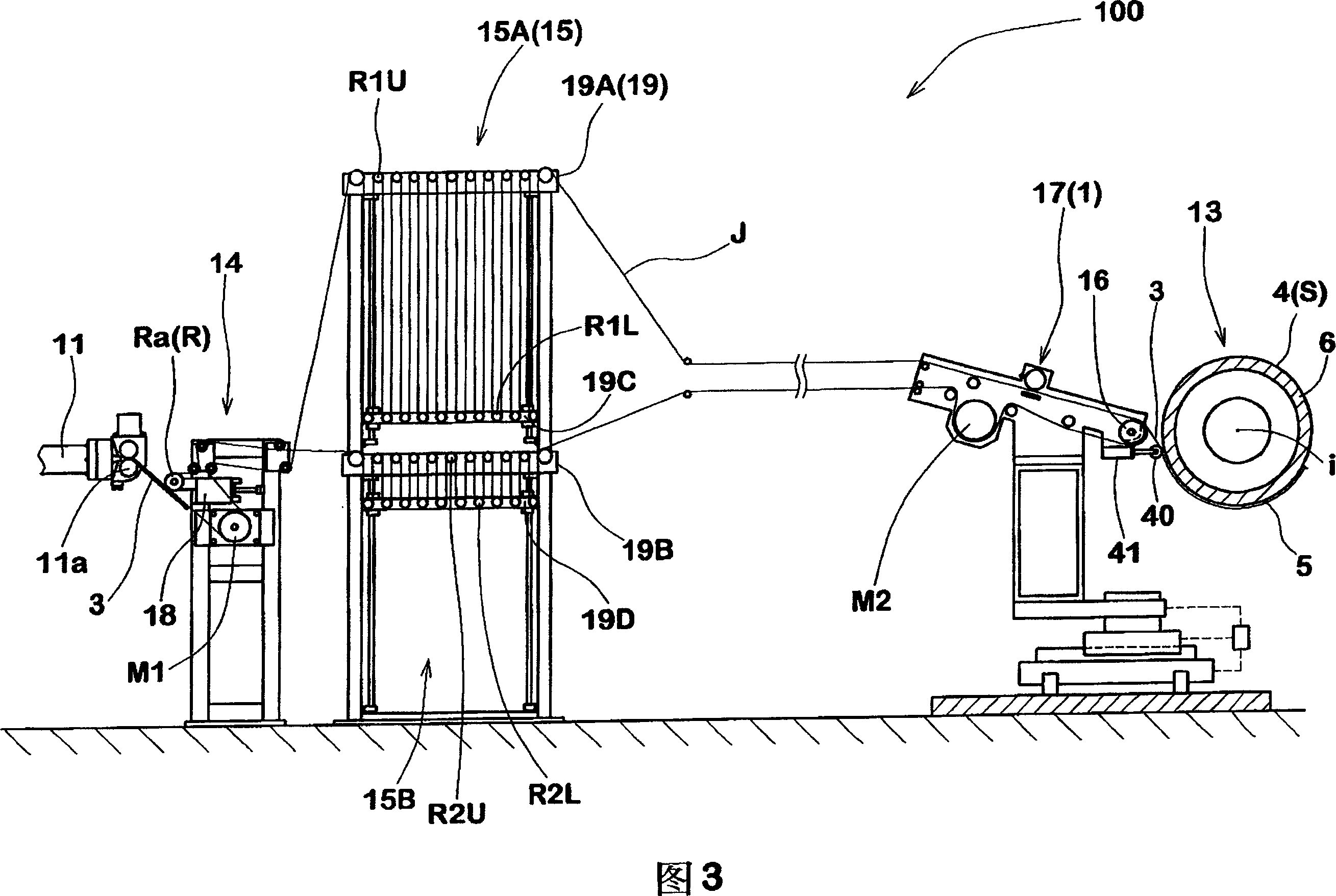

[0025] In the drawings, a device for applying a rubber belt (hereinafter referred to as "belt application device 1") according to the present invention is a device that feeds and applies a long continuous raw rubber belt 3 onto a winding surface S of a rotating object 4. A means of winding 5 of rubber band 3 is thus formed around object 4 .

[0026] In this embodiment, as shown in FIG. 3 , the tape applying device 1 is incorporated in an apparatus 100 for manufacturing a tread assembly of a motorcycle pneumatic tire T, which includes an extruder 11 for extruding the tape 3 forms of raw rubber; belt applicator 1; and forming drum 6. Thus, in this embodiment, the aforementioned rotating body 4 generally refers to the forming drum 6 itself and the material previously wound around the drum 6 .

[0027] Further, as shown in FIG. 7, the motorcycle tire T includes: a tread portion Tt; a pair of axially spaced bead portions Tb each having a bead core Tc therein; a pair of sidewall po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com