Closed circuit grinding classification system consisting of cyclone and grate discharge ball mill

A technology of closed-circuit grinding and grading system, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems that the grinding capacity of the grid-type ball mill cannot be fully utilized, the operating rate of the ball mill has decreased, and there is no success, etc., to achieve Small footprint, increased grinding capacity, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

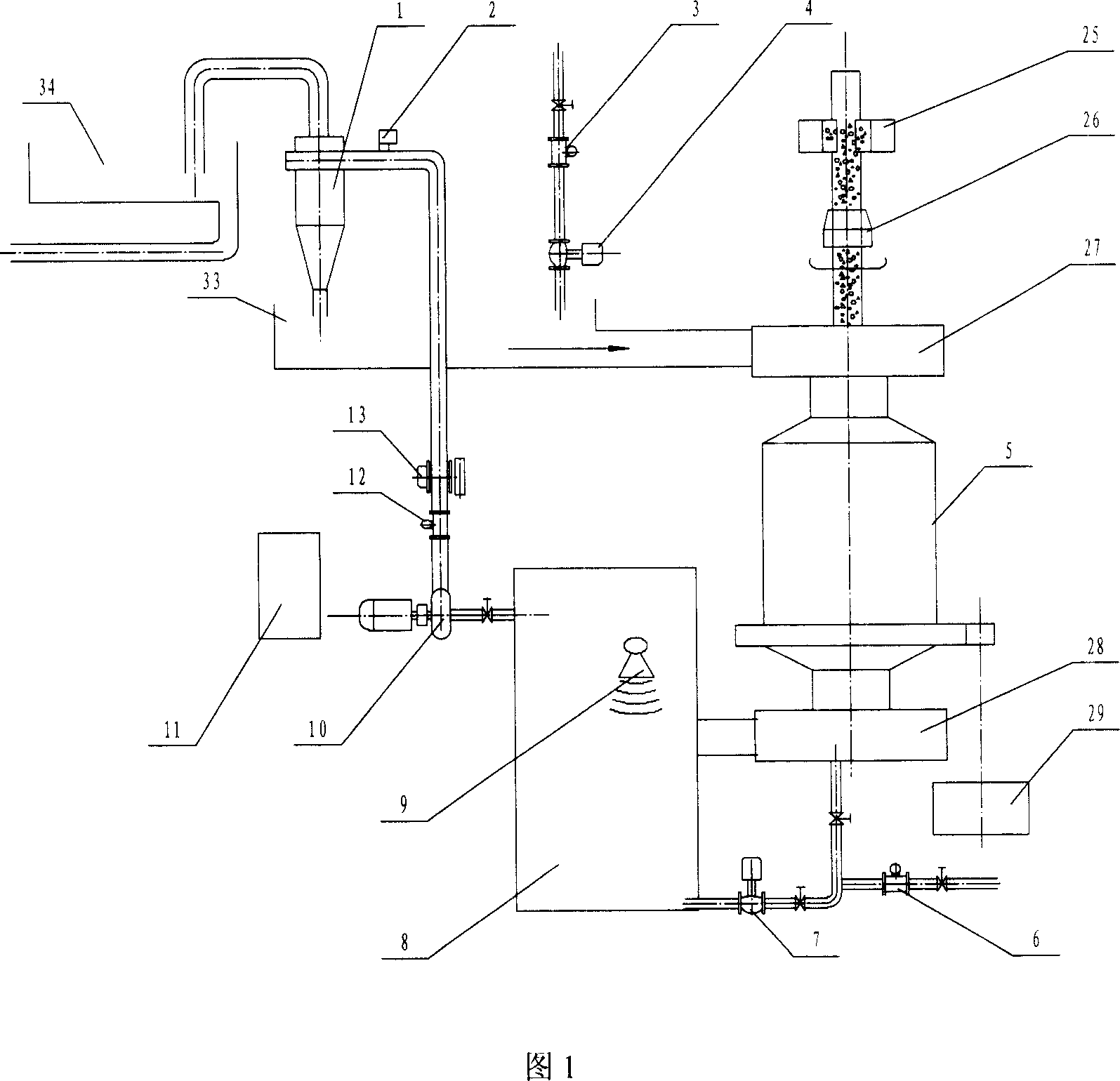

Embodiment 1

[0015] See Figure 1, cyclone-grid ball mill closed-circuit grinding and grading system, the system consists of a grid ball mill 5, a slurry tank 8, a slurry pump 10, a frequency converter 11, a cyclone 1, an automatic water supply device 3, 4, 6, 7, and pipelines. The system selects a single cyclone that matches the processing capacity of the grid-type ball mill. The inlet of the cyclone 1 is connected with a slurry pump 10 whose speed is regulated by a frequency converter 11. The slag The inlet of the slurry pump 10 is connected to the pulp tank 8, and the inlet of the pulp tank 8 is connected to the ore discharge port of the grid-type ball mill 5; the underflow (sand settling) of the cyclone 1 returns to the ore feeding port 27 of the grid-type ball mill 5 through the launder 33; The overflow port of the device 1 is connected with the next procedure through the launder 34 .

[0016] The inlet of the cyclone 1 is equipped with a pressure detection device 2 , a flow detection ...

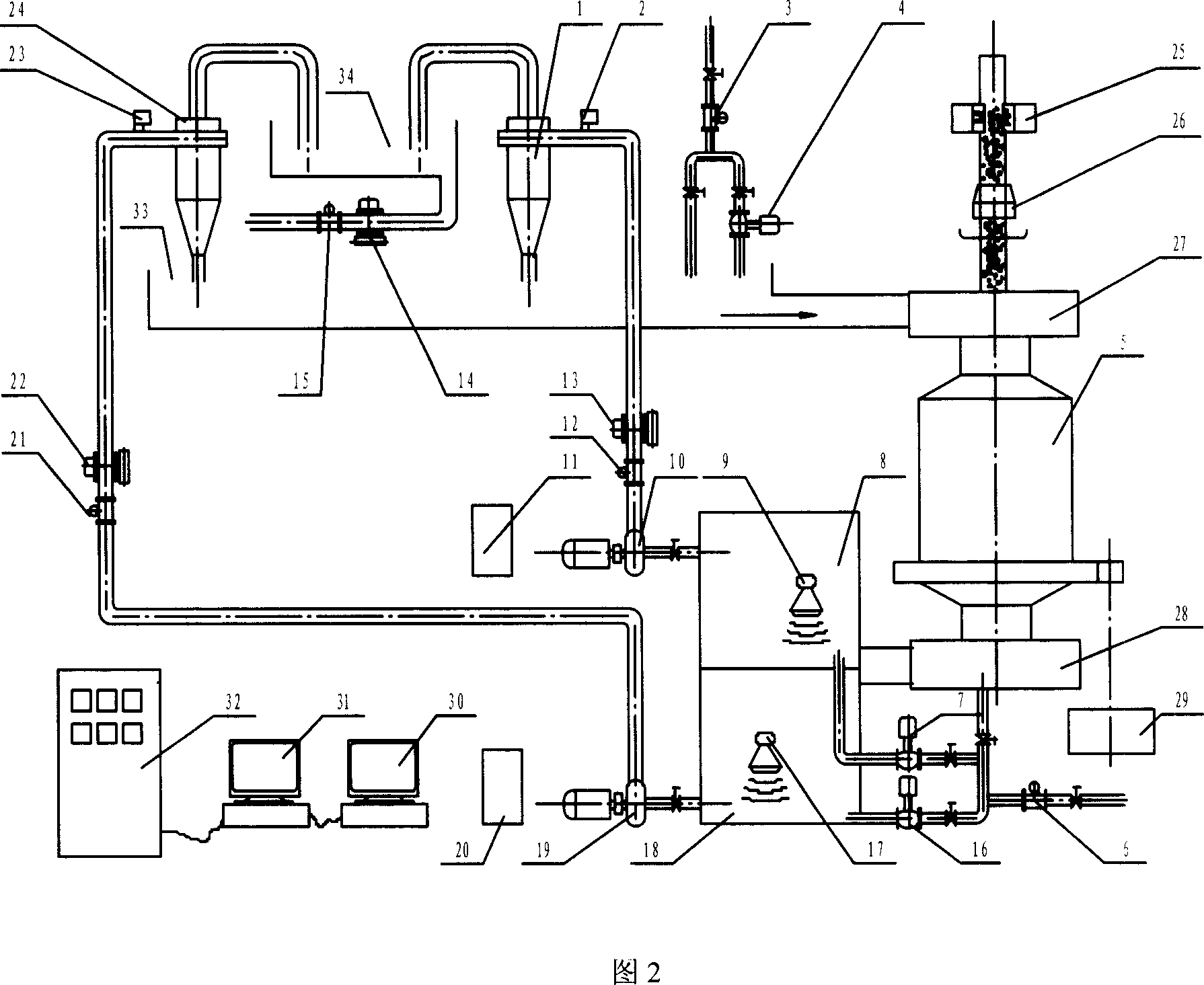

Embodiment 2

[0021] As shown in Figure 2, this embodiment adopts two sets of cyclone classification systems, one working and one standby, to match the same grid-type ball mill, which can minimize the problem of the reduction in the operation rate of the grid-type ball mill caused by the failure of the classification equipment. Select two sets of single cyclones 1 and 24 that match the processing capacity of the grid-type ball mill 5, and each cyclone inlet is equipped with a pressure detection device 2, a flow detection device 12, a concentration detection device 13 and a pressure detection device 23 , flow detection device 21, concentration detection device 22, the pulp to be classified by the inlet of the cyclone is sucked and transported by the slurry pumps 11 and 19 from the pulp tanks 8 and 18 provided at the discharge port of the grid type ball mill respectively, and the cyclone The overflow of the cyclone is the graded product of the system (flow and concentration detection devices 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com