Knitting method for knitting fabric, knitting fabric, and knitting program

A technology of knitted fabrics and empty needles, which is applied in the field of knitting, can solve the problems of not being open, etc., and achieve the effect of good drooping and good knitting conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

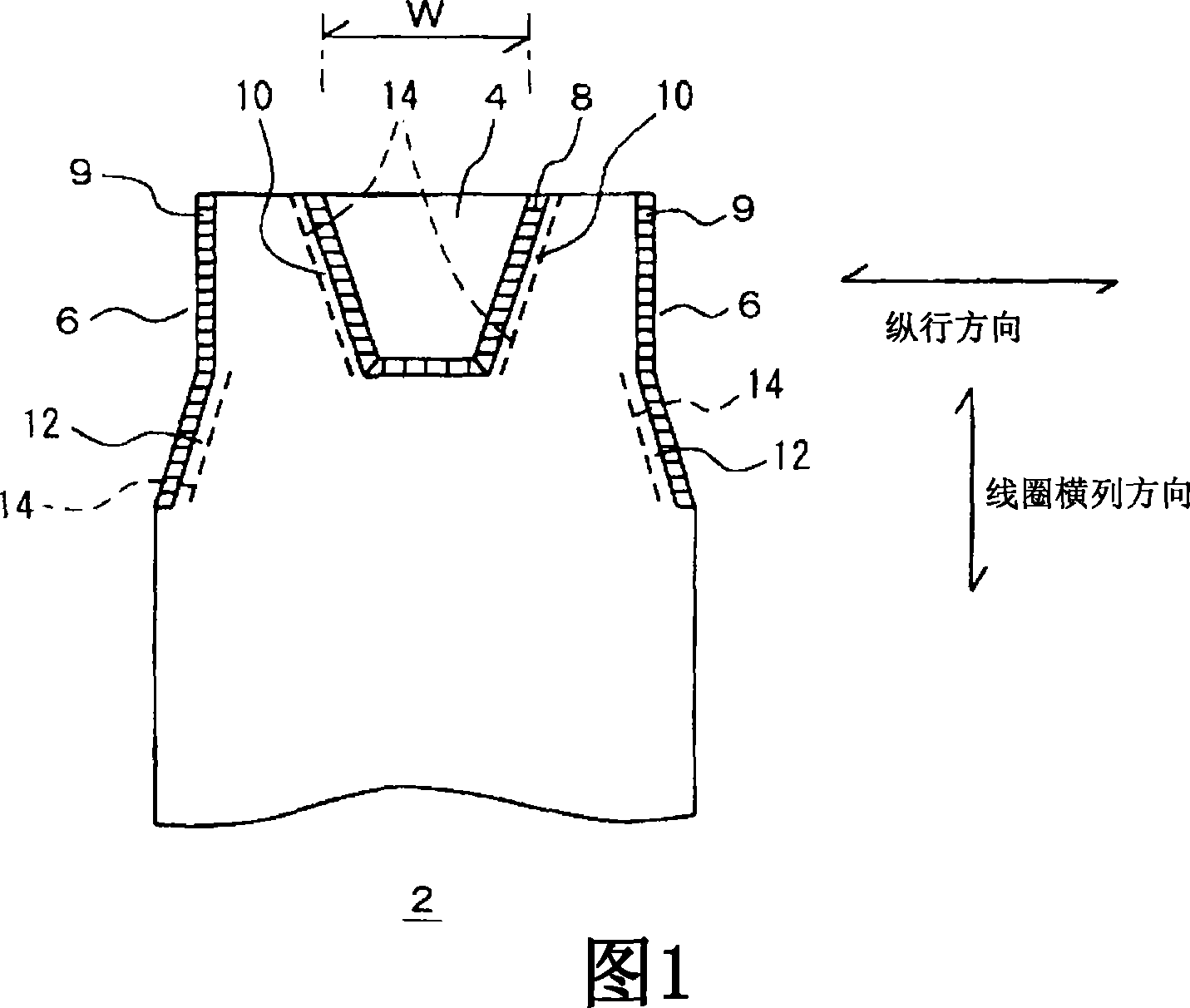

[0059] An exemplary embodiment and variants thereof are shown in FIGS. 1 to 13 . In Fig. 1 to Fig. 4 represent the knitted clothes knitted in the embodiment, 2 of Fig. 1 is an undershirt, wherein, 4 is a neckline; 6 is an armhole; 8 is a collar, knitting on the neckline 4; 9 is along the armhole 6 woven underarm ribs. The knitted garment part 10 inside the collar 8 and the knitted garment part 12 inside the armpit rib 9 are knitted garment parts woven in the embodiment, and the ends on the neckline 4 and armhole 6 sides are the ends of the knitted garment parts 10, 12. department. In addition, 14 is a forming line accompanying the knitting of the garment parts 10 and 12, and is a row of overlapping stitches.

[0060] The undershirt 2 is tubular-knitted seamlessly using a flat knitting machine such as 2-needle beds or 4-needle beds. The opening on the top of the collar 8 is called the upper collar, and W represents its width. Furthermore, in the embodiment, in the body of k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com