Method for preparing Nano silver piece

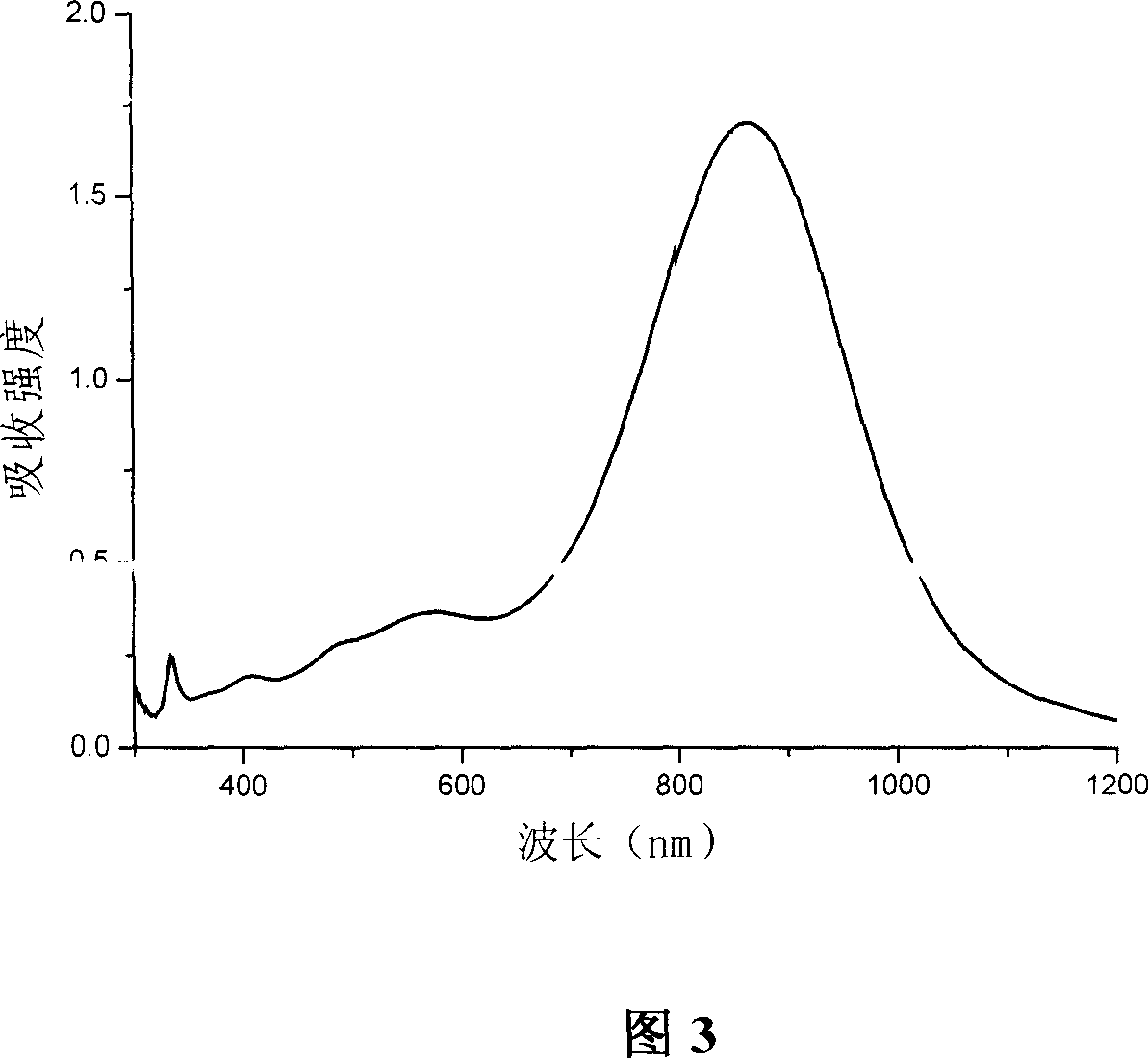

A technology of silver nanosheets and silver nanoparticles is applied in the field of preparation of silver nanosheets, which can solve the problems such as difficulty in controlling the size of silver nanosheets, and achieve the effects of simple method, good stability and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

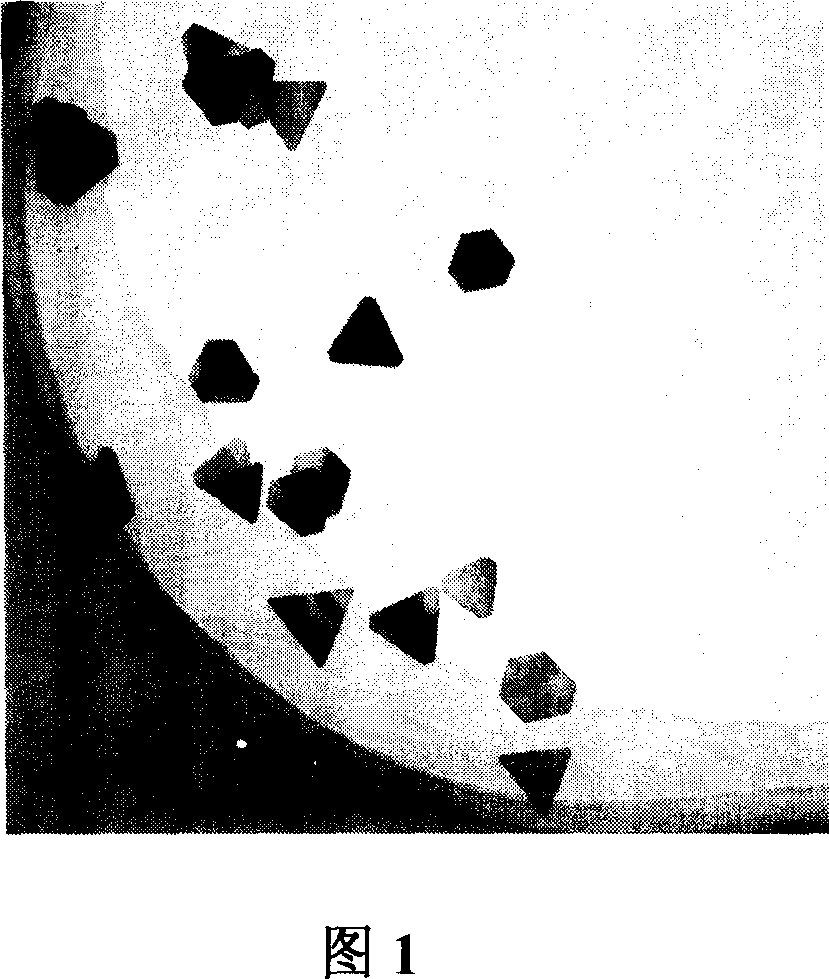

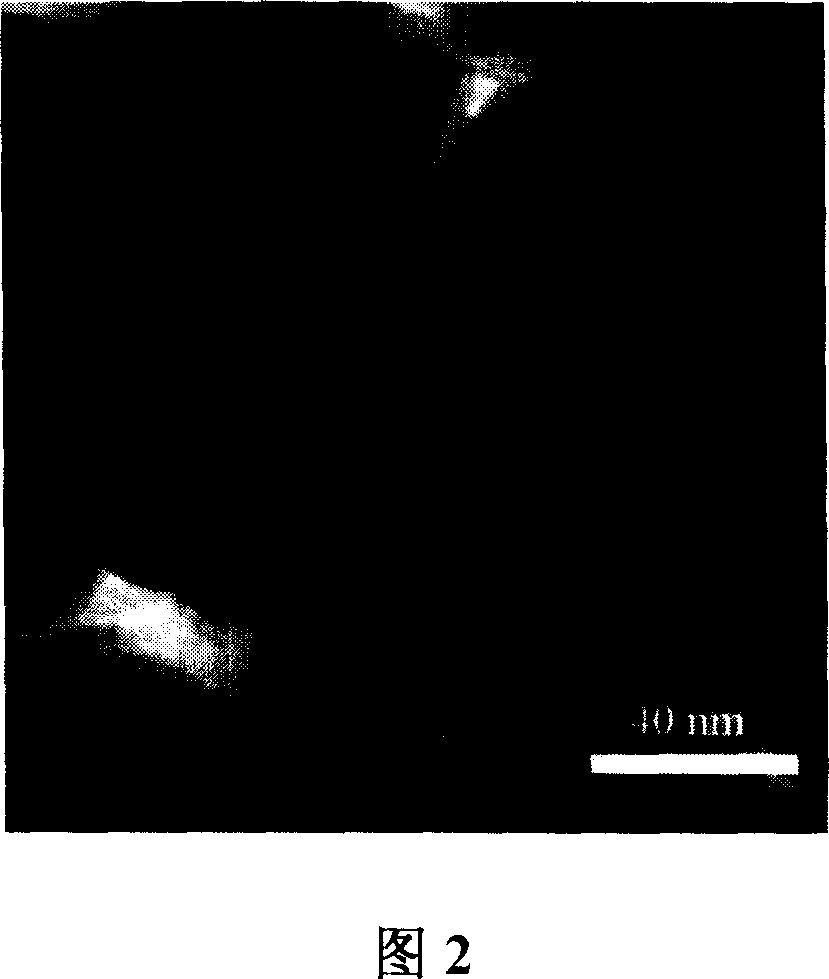

[0022] (1) Preparation of seeds: in the presence of 0.05mM AgNO 3 and 0.15mM sodium citrate in 100mL pure water, quickly add 1mL 30mM NaBH 4 , stirred for 1 hour, and the size of the obtained silver nanoparticles was 2.0-15.0 nm.

[0023] (2) Preparation of silver nanosheets: Prepare two solutions A and B. The composition of solution A: add 1.0 mL of the prepared seeds above to 60 mL of pure aqueous solution containing 0.6 mM hydrazine hydrate and 0.2 mM sodium citrate. Composition of solution B: 30mL containing 0.6mM AgNO 3 of aqueous solution. Then solution B was added dropwise into solution A (1 mL / min), and stirring was continued for 10 min after the addition was complete. The size of the obtained silver flakes is 83-95nm.

Embodiment 2

[0025] (1) Preparation of seeds: in the presence of 0.2mM AgNO 3 and 0.6mM sodium citrate in 100mL pure water, quickly add 1mL 120mM NaBH 4 , stirred for 1 hour, and the size of the obtained silver nanoparticles was 2.0-15.0 nm.

[0026] (2) Preparation of silver nanosheets: Prepare two solutions A and B. The composition of solution A: 0.7 mL of the above prepared silver nano-seeds were added to 60 mL of pure aqueous solution containing 0.6 mM hydrazine hydrate and 0.2 mM sodium citrate. Composition of solution B: 30mL containing 0.6mM AgNO 3 of aqueous solution. Then solution B was added dropwise into solution A (1 mL / min), and stirring was continued for 10 min after the addition was complete. The size of the obtained silver flakes is 63-76 nm.

Embodiment 3

[0028] (1) Preparation of seeds: in the presence of 1mM AgNO 3 and 3mM sodium citrate in 100mL pure water, quickly add 1mL 600mM NaBH 4 , stirred for 1 hour, and the size of the obtained silver nanoparticles was 2.0-15.0 nm.

[0029] (2) Preparation of silver nanosheets; prepare two solutions A and B. The composition of solution A: 0.5 mL of the prepared silver nano-seeds was added to 60 mL of pure aqueous solution containing 0.6 mM hydrazine hydrate and 0.2 mM sodium citrate. Composition of solution B: 30mL containing 0.6mM AgNO 3 of aqueous solution. Then solution B was added dropwise into solution A (1 mL / min), and stirring was continued for 10 min after the addition was complete. The size of the obtained silver flakes is 70-83nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com