Dipolar membranes of middle boundary layer of complexation metal catalysis, and preparation method

A complex metal and bipolar membrane technology, applied in the field of electrodialysis, can solve the problem of high cost of separating lactic acid, and achieve the effects of not easy to fall off or dissolve, long service life and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Embodiment 1: The complex metal-catalyzed intermediate interface layer bipolar membrane in this embodiment is composed of a cation exchange membrane layer, an intermediate interface layer containing a complex metal catalyst, and an anion exchange membrane layer.

[0031] Wherein: the complex metal catalyst is a metal complex containing Sn, Cr, Ni, Fe, Ru, Mn, Ti, Co, Cu, Pt, Rb or Zn; the cation exchange membrane layer contains 15 to 25 wt .% of sulfonated polyphenylene ether; the anion exchange membrane layer contains 15-25wt.% of chloromethylated polysulfone.

specific Embodiment approach 2

[0032] Specific embodiment 2: In this embodiment, a complex metal-catalyzed intermediate interface layer bipolar membrane is prepared according to the following steps:

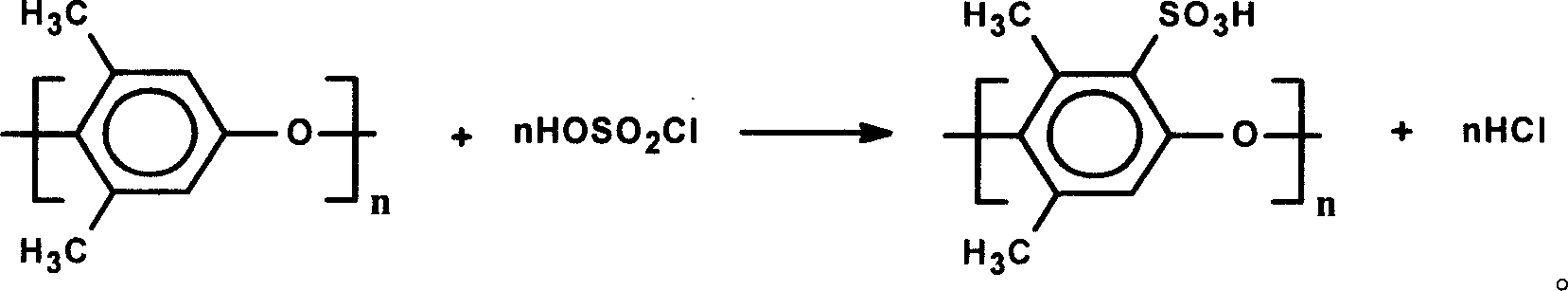

[0033] a. Preparation of cationic membrane material: take the dried polyphenylene ether and dissolve it in anhydrous and alcohol-free chloroform, add dropwise the mixed solution formed by dissolving the sulfonating agent in anhydrous and alcohol-free chloroform, control the sulfonating agent and polyphenylene ether The molar ratio of ether is 0.8:1 to 1:1.4, and the dropwise addition is completed in about 20 to 40 minutes. The reaction temperature is controlled at 23 to 28°C, the reaction time is 3 to 7 hours, and it is left to stand for 20 to 40 minutes. The substance precipitated out, and the upper clear night was poured out, and the remaining viscous substance was poured into deionized water, washed and filtered, then transformed in NaCl solution, and dried for later use.

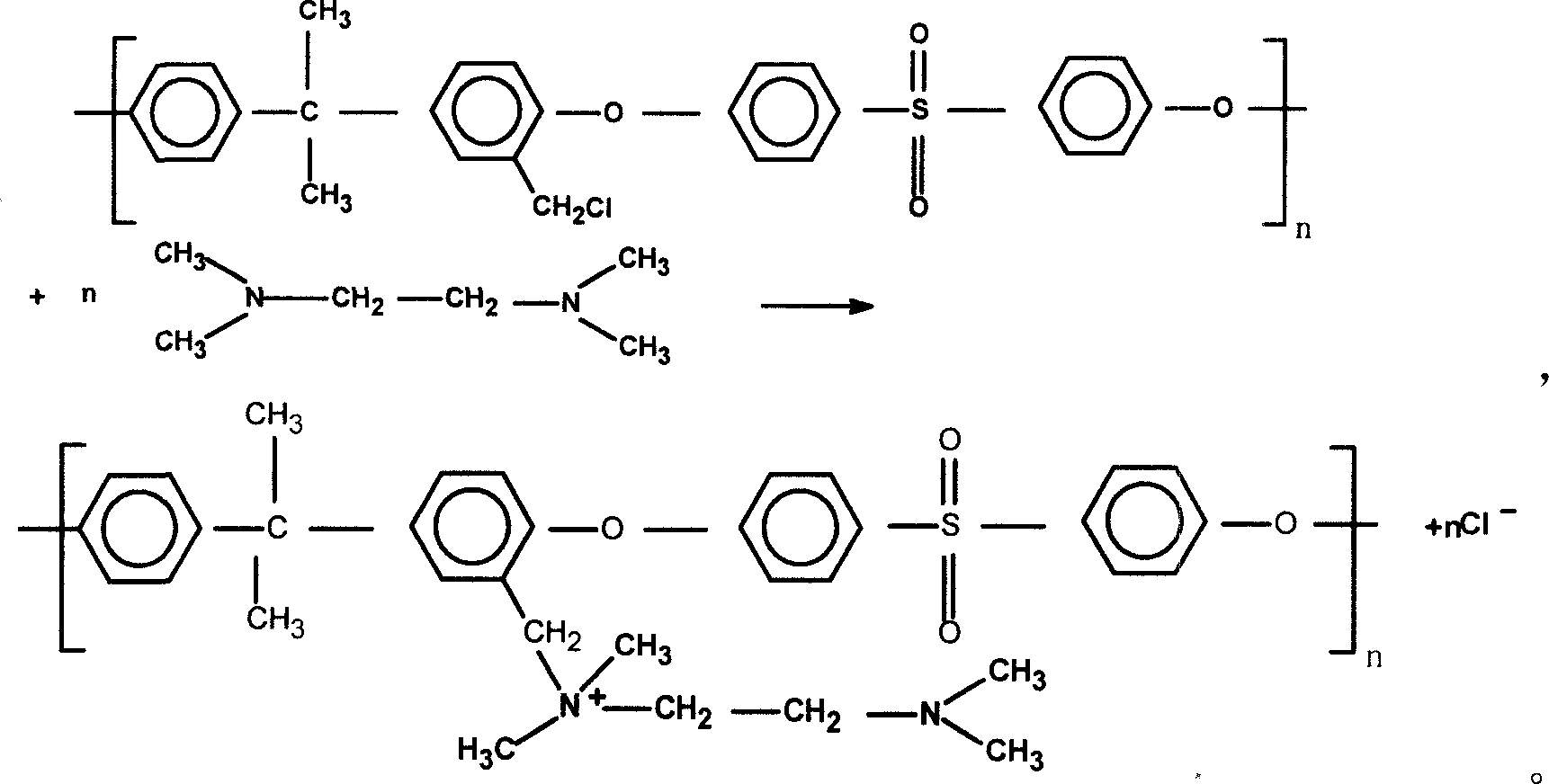

[0034] b. Preparation of anion me...

specific Embodiment approach 3

[0040] Specific implementation mode three: In this implementation mode, a complex metal-catalyzed intermediate interface layer bipolar membrane is prepared according to the following steps:

[0041] a. Preparation of cationic membrane material: take the dried polyphenylene ether and dissolve it in anhydrous alcohol-free chloroform, add dropwise the mixed solution formed by dissolving the sulfonating agent in anhydrous alcohol-free chloroform, control the sulfonating agent and polyphenylene ether The molar ratio of phenyl ether is 0.9:1, the dropwise addition is completed in 25 minutes, the reaction temperature is controlled at 26°C, the reaction time is 5 hours, and it is left to stand for 20 to 40 minutes, flocculent viscous matter is precipitated, and the upper layer is poured out to clear the night, and the remaining Pour the viscous material into deionized water, wash and filter, then invert in 0.5-2mol / L NaCl solution, and dry it for later use.

[0042] b. Preparation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com