Steel with high mechanical strength and wear resistance

A technology with mechanical strength and high wear resistance, applied in the field of steel with high mechanical strength and high wear resistance, it can solve the problems of reducing the impact resistance of the workpiece and the fragile area of strong bending load resistance, processing or welding difficulties and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

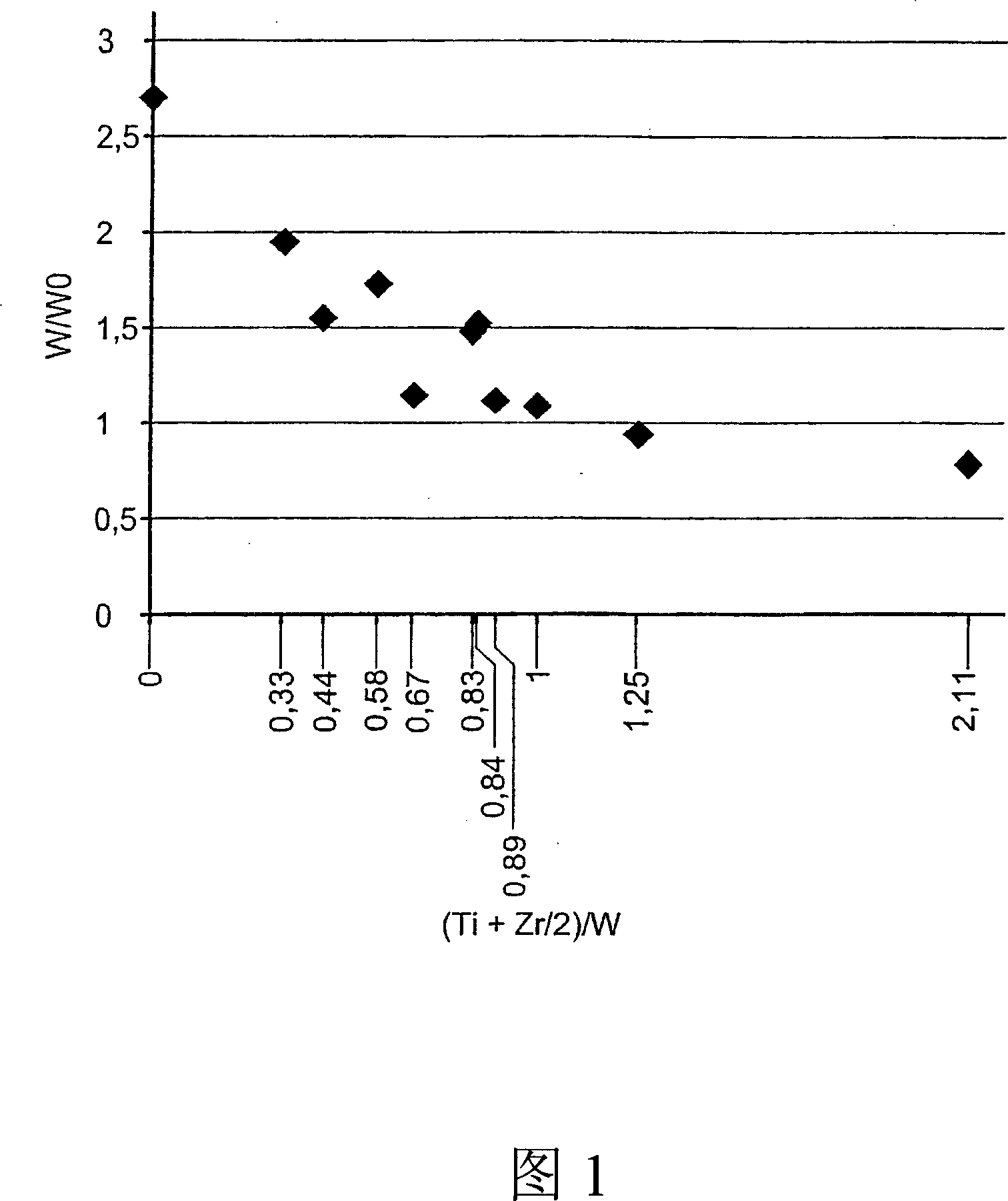

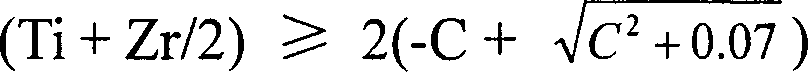

[0089] The invention will now be described in more detail, but in a non-limiting manner, and illustrated with reference to examples and a graph showing the fractionation ratio of tungsten versus (Ti+Zr / 2) / W for various steels .

[0090] Tungsten is known to be an alloying element whose effect on steel properties is comparable to that of molybdenum. In particular, tungsten is known to have a comparable effect on hardening and heat softening resistance as molybdenum at a ratio of two parts tungsten to one part molybdenum. However, except in some very highly alloyed steels not covered by the present invention, tungsten is rarely used, especially since it is much more expensive than molybdenum. Like molybdenum, tungsten also has the disadvantage of being very strongly segregated and causing very hard and very brittle segregated joints.

[0091] The inventors have demonstrated in a novel and surprising manner that the segregation of tungsten is greatly attenuated in the presence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com