Refrigerant tank with volume below 1000ml

A refrigerant and tank body technology, applied in the field of refrigerant tank capping, can solve the problems of large refrigerant leakage, refrigerant moisture content reaching the standard, water content exceeding the standard, etc., saving resources, saving investment in production equipment, and eliminating the need for special The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

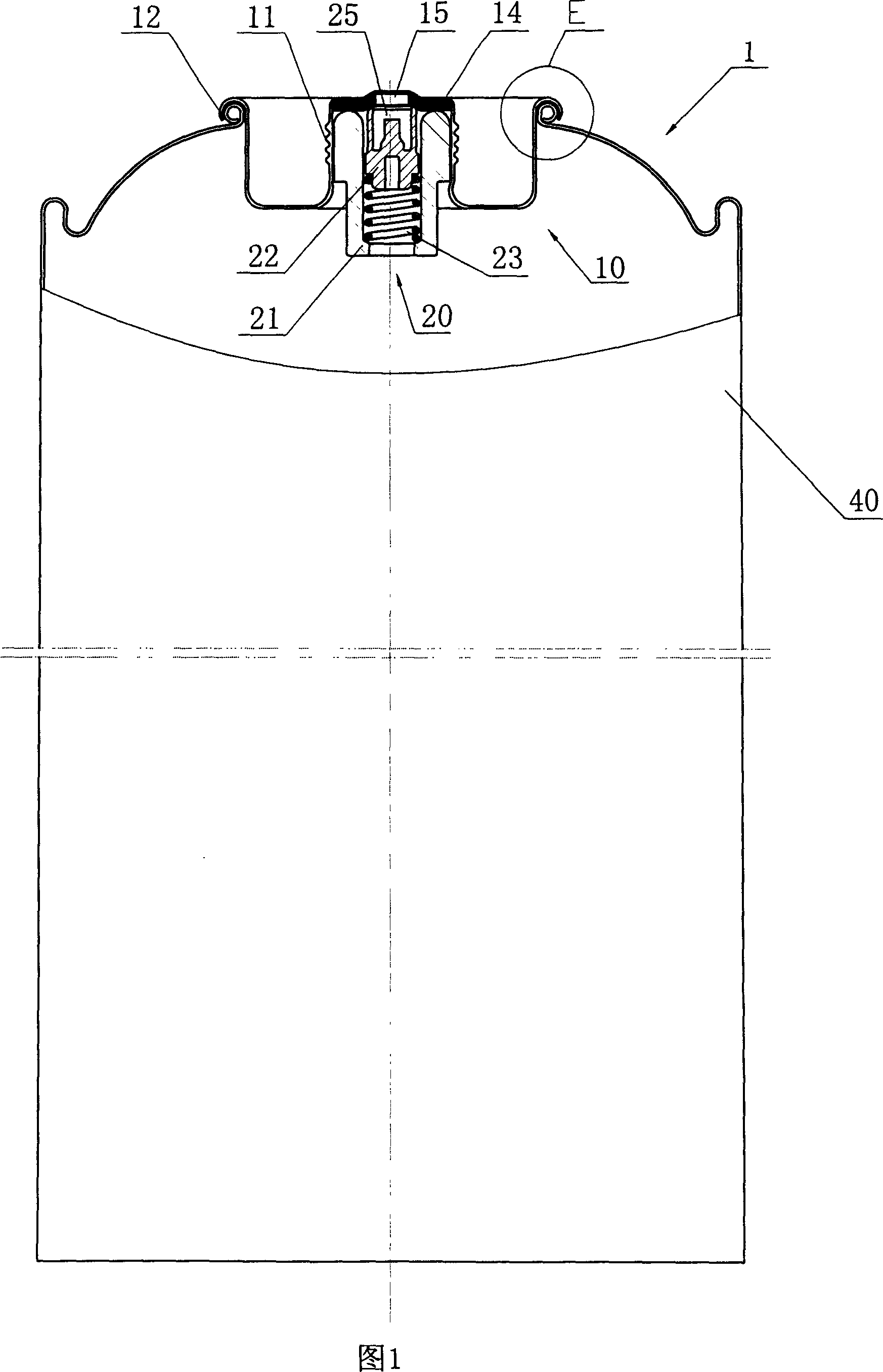

[0024] In this embodiment, a 600 milliliter refrigerant tank is used to fill 330 grams of hydrocarbon refrigerant. The steps are as follows:

[0025] a) Install the threaded aerosol valve for a while

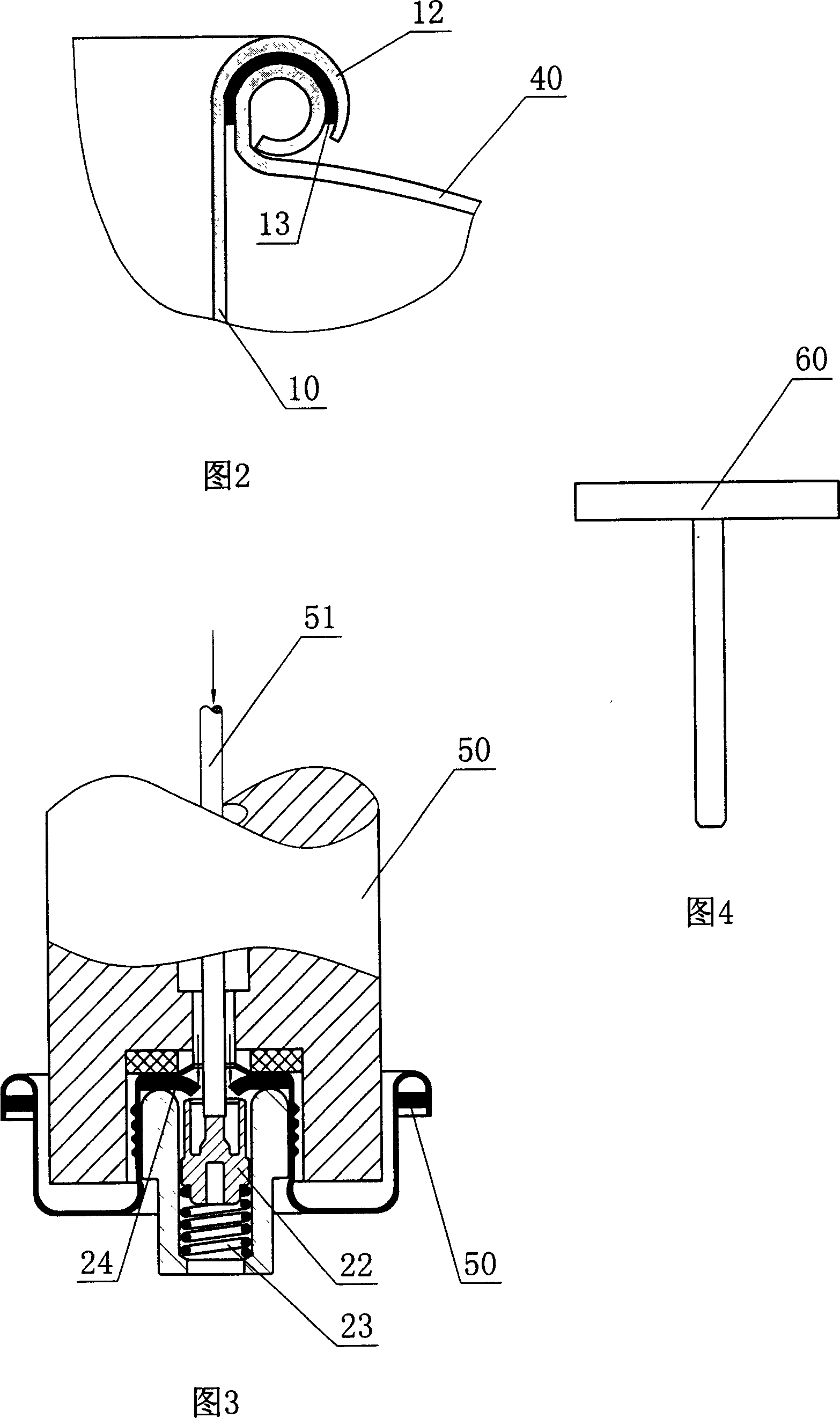

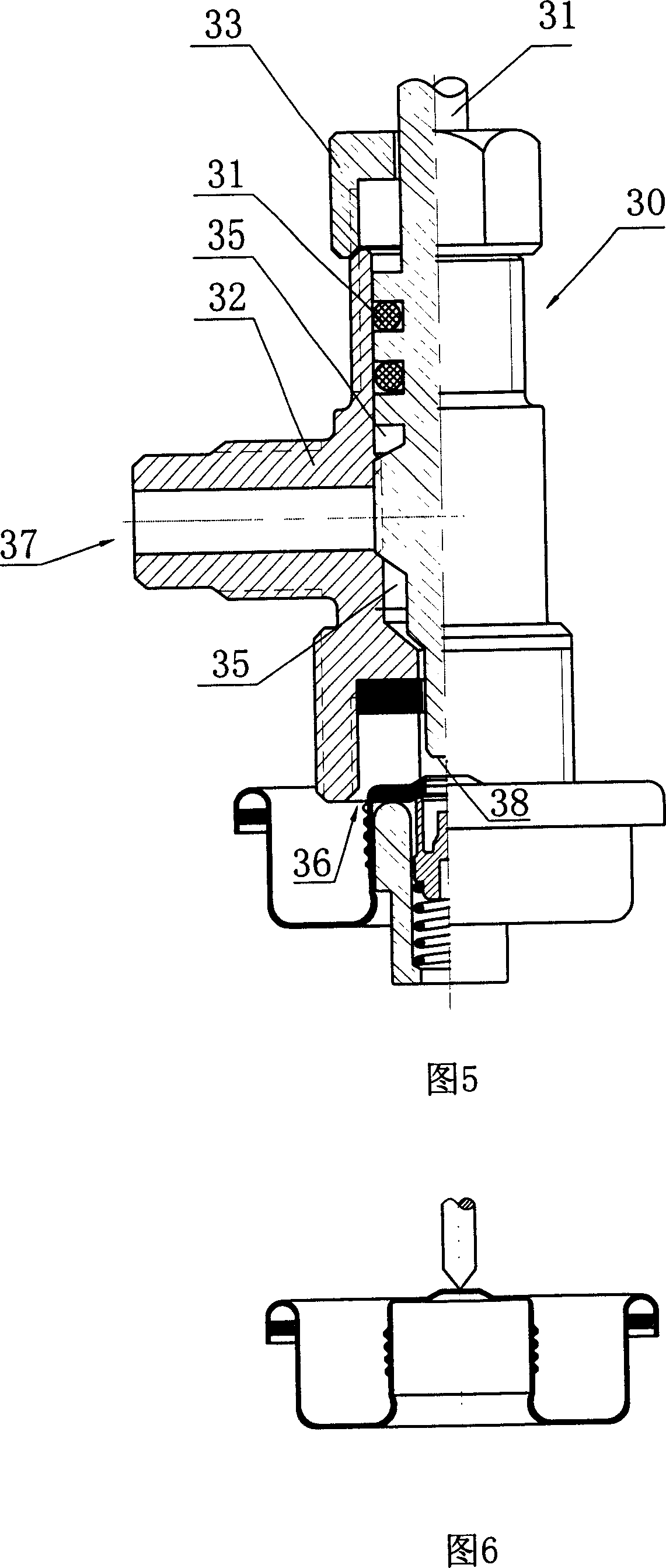

[0026] A washer 14 is placed in the cylindrical boss 11 at the center of the cover body 10 shown in FIG. 1 , and the temporary threaded aerosol valve is pressed into the boss 11 . This momentary threaded aerosol valve is made up of valve seat 21, valve core 22, and stage clip 23, stage clip 23 is placed in the inner hole 25 of valve seat, valve core 22 is connected on the free end of stage clip 23 upper side, can With the expansion and contraction of the compression spring 23, it moves axially in the inner hole 25 of the valve seat. The valve core 22 corresponds to and communicates with the top circular hole 15 of the boss 11 , and the valve seat 21 and the upper end surface of the valve core 22 are tightly pressed on the gasket 14 to be in sealing connection therewith.

[00...

Embodiment 2

[0038]In this embodiment, a 400 ml refrigerant tank is used to fill R134a. The concrete steps of the structure of the capping and the bottle opening key and the filling and discharging method of the refrigerant are the same as in Embodiment 1. Wherein, the gasket 14 and the sealing ring 13 used in the refrigerant tank are all made of solvent-resistant rubber.

Embodiment 3

[0040] This embodiment is filled with a 300 milliliter refrigerant tank? R12. The concrete steps of the structure of the capping and the bottle opening key and the filling and discharging method of the refrigerant are the same as in Embodiment 1. Wherein, the gasket 14 and the sealing ring 13 used in the refrigerant tank are all made of solvent-resistant rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com