Thermal vacuum deposition method and device

A technology of thermal vacuum and deposition equipment, applied in vacuum evaporation plating, ion implantation plating, metal material coating process, etc., can solve the problems of substrate damage, a lot of time and cost of baseband, and unusable substrate. Achieve the effect of reducing space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

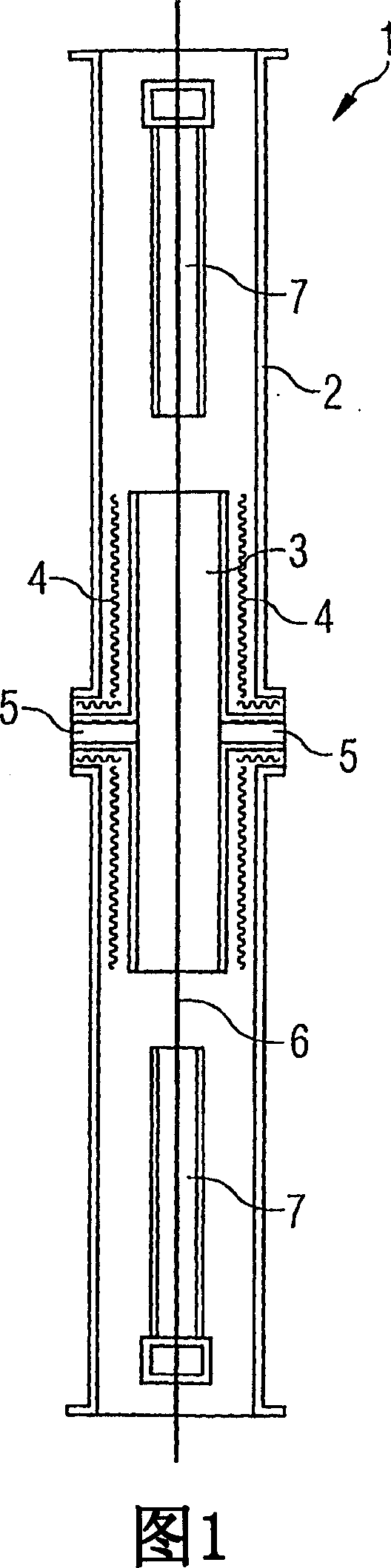

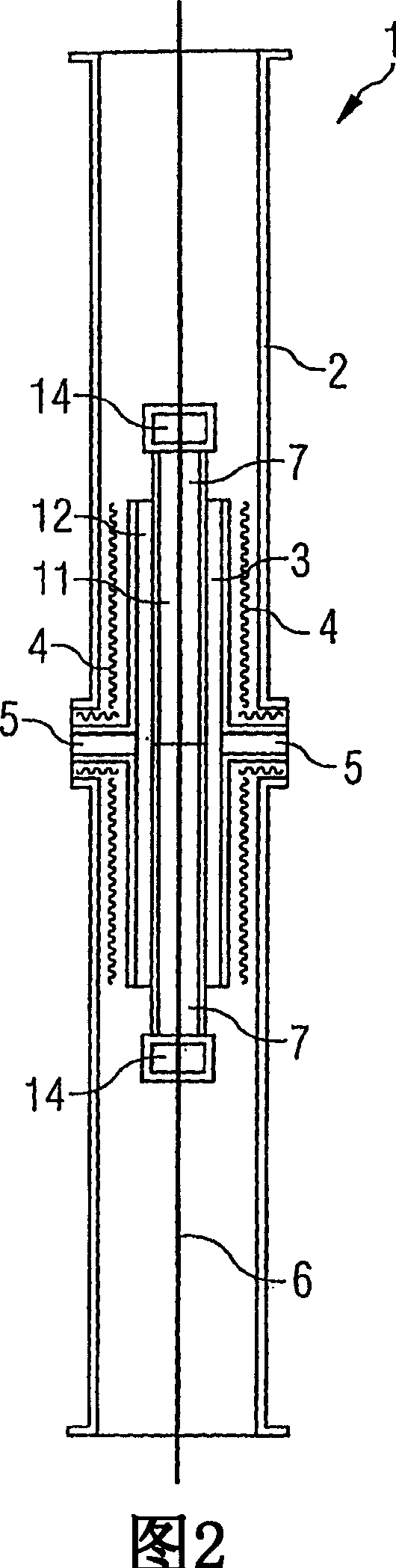

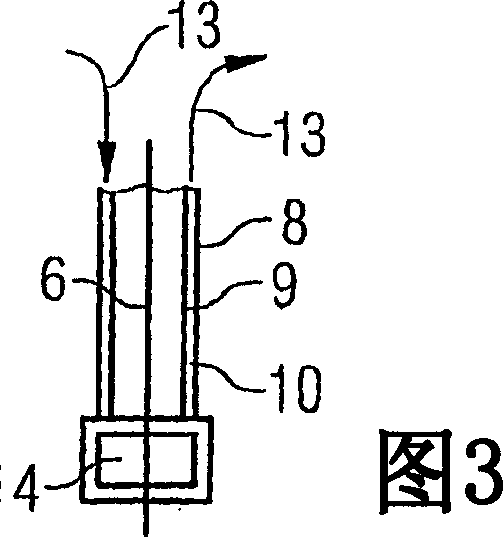

[0030] FIG. 1 shows a deposition apparatus 1 according to the invention with a vacuum chamber 2 and vaporization channels 3 arranged therein. The vaporization channel 3 has a height of about 4 meters and is arranged at an intermediate level of the vacuum chamber 2 at a height of about 10 meters. The vaporization channel 3 has a tall, elongated, hollow cuboid shape, and is opened at the base at the top and bottom ends.

[0031] At an intermediate level of the vacuum chamber 2 and of the vaporization channel 3, in the operating position substantially horizontally aligned nozzles 5 are mounted on two opposite sides, namely on either side of the substrate, the nozzles The tube feeds its narrow end into the vaporization channel 3 . The other end of the spray pipe 5 is connected to an evaporation device for evaporating the coating material.

[0032]The tape-shaped substrate 6 is conveyed through the vacuum chamber 2 and the vaporization channel 3 . The substrate 6 is aligned in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com