Thick matter piston pump

A material pump and piston technology, applied in the control field of thick material pump, can solve problems such as impossibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

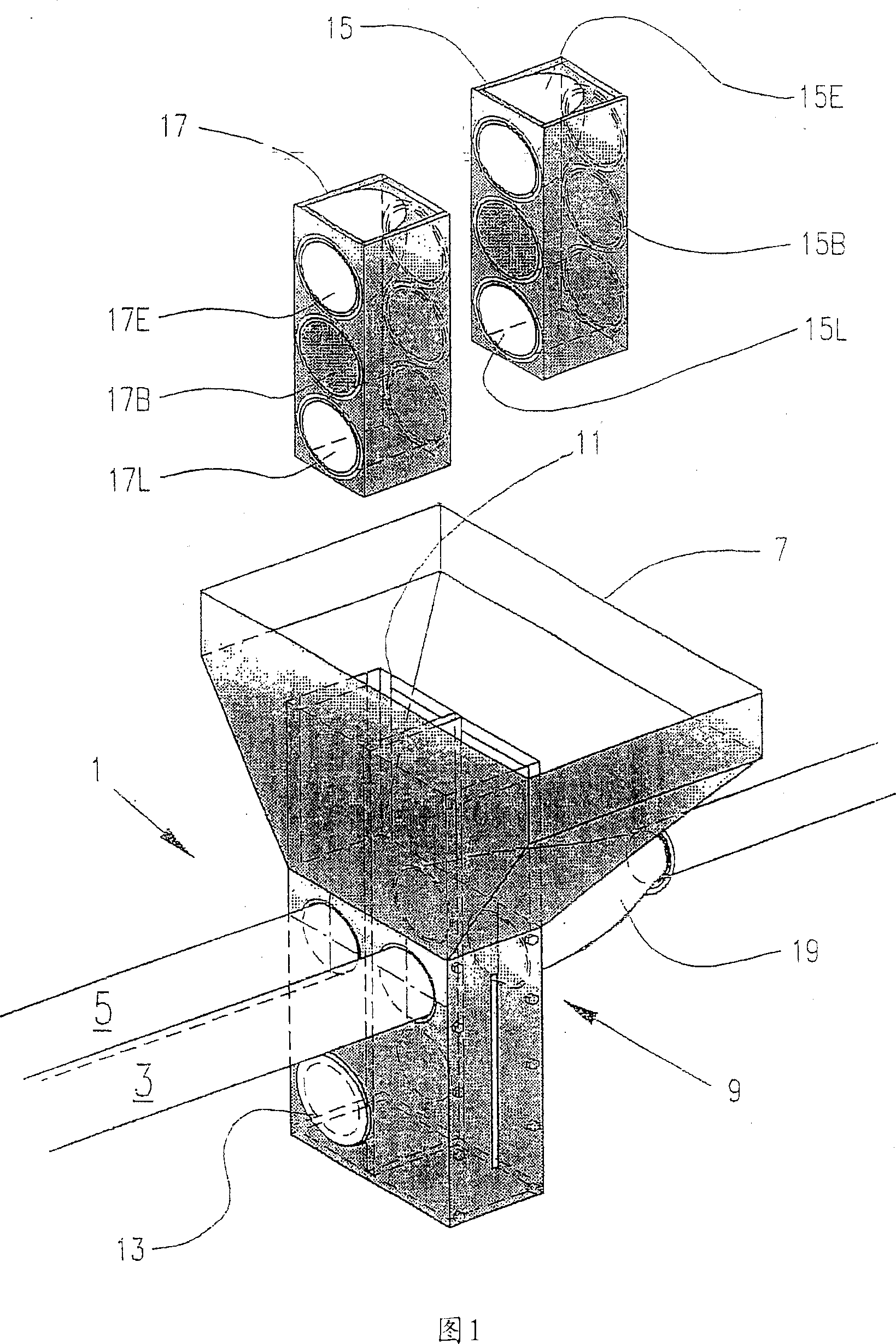

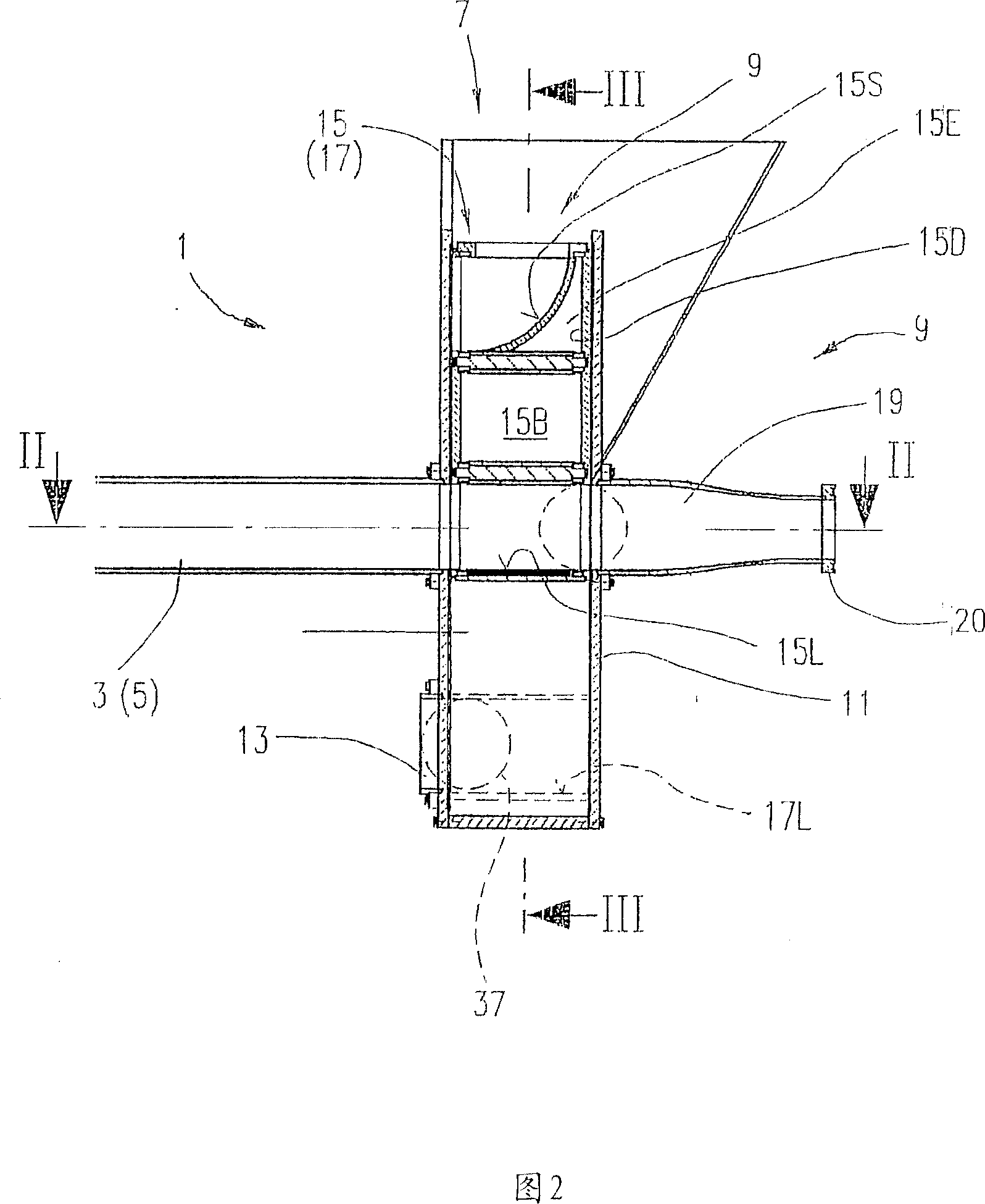

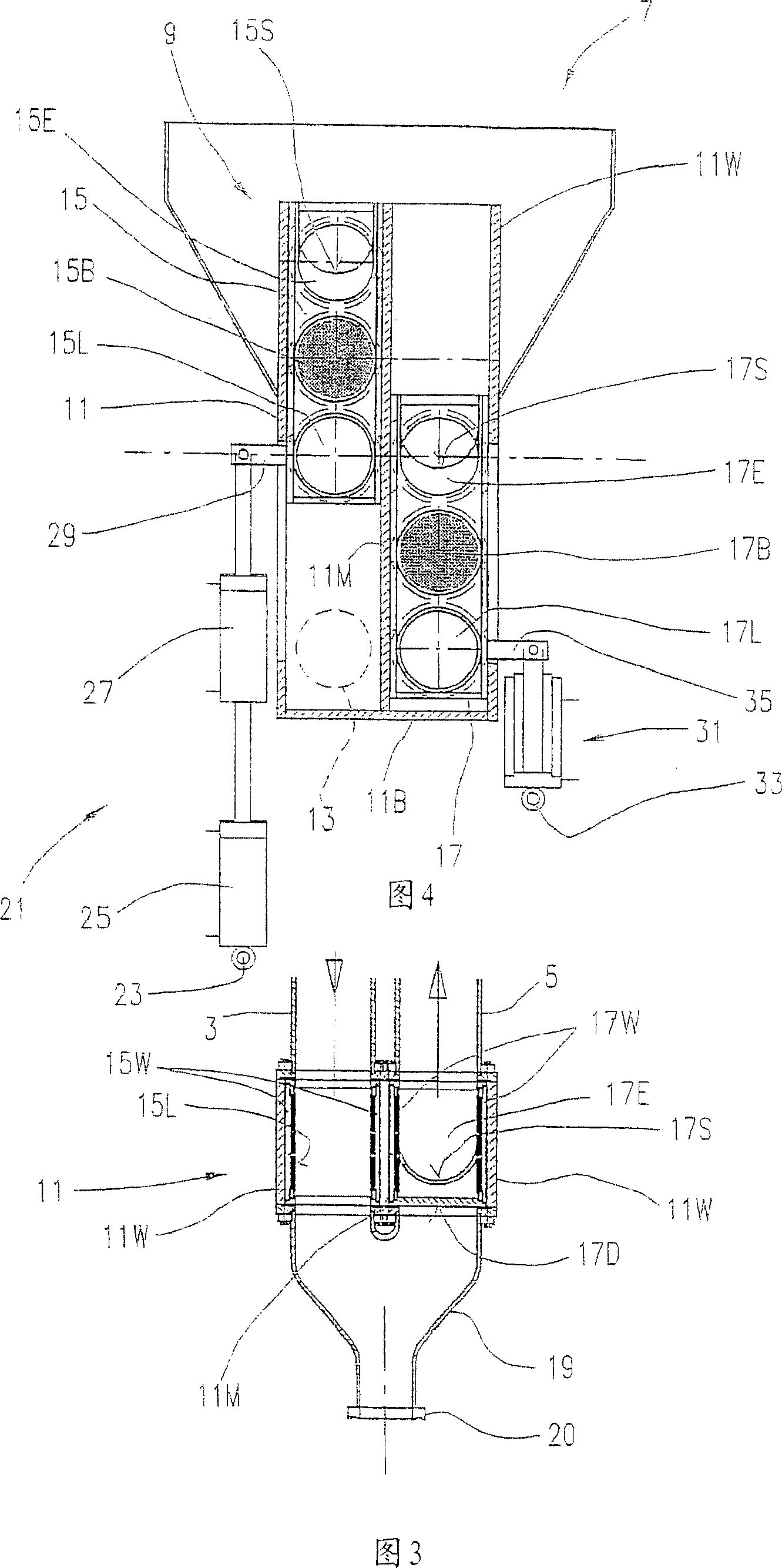

[0042] Figure 1 shows a three-dimensional outline view of a thick substance pump 1 with two parallel delivery cylinders 3 and 5 placed next to each other, a prefill container 7, a switching valve 9, a collector or a Y-shaped pipe 19 And the brief part of the feeding pipeline. Said switching valve is located in the housing, or in the guide structure 11 , extending through the bottom of the prefilled container 7 . Near the bottom of the guide structure, on the side facing the delivery cylinders 3 and 5, a maintenance flap 13 is provided. Above said prefilled container, two control slides 15 and 17 are shown in a developed-like manner, which are intended to be movably inserted into the chamber-shaped guide structure 11 of the switching valve 9 forming its valve body. This will be detailed later.

[0043] Figure 2 shows only the delivery cylinder 3 of the thick matter pump 1, which is located at the front of the view, in its open (discharge) end portion. The piston associated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com