Turnover device and method

A technology of flipping device and control device, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low reliability, high flipping fragmentation rate, shortening the time of line change operation, etc., so as to reduce equipment cost and solve flipping fragmentation rate. The effect of excessively high and shortened working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

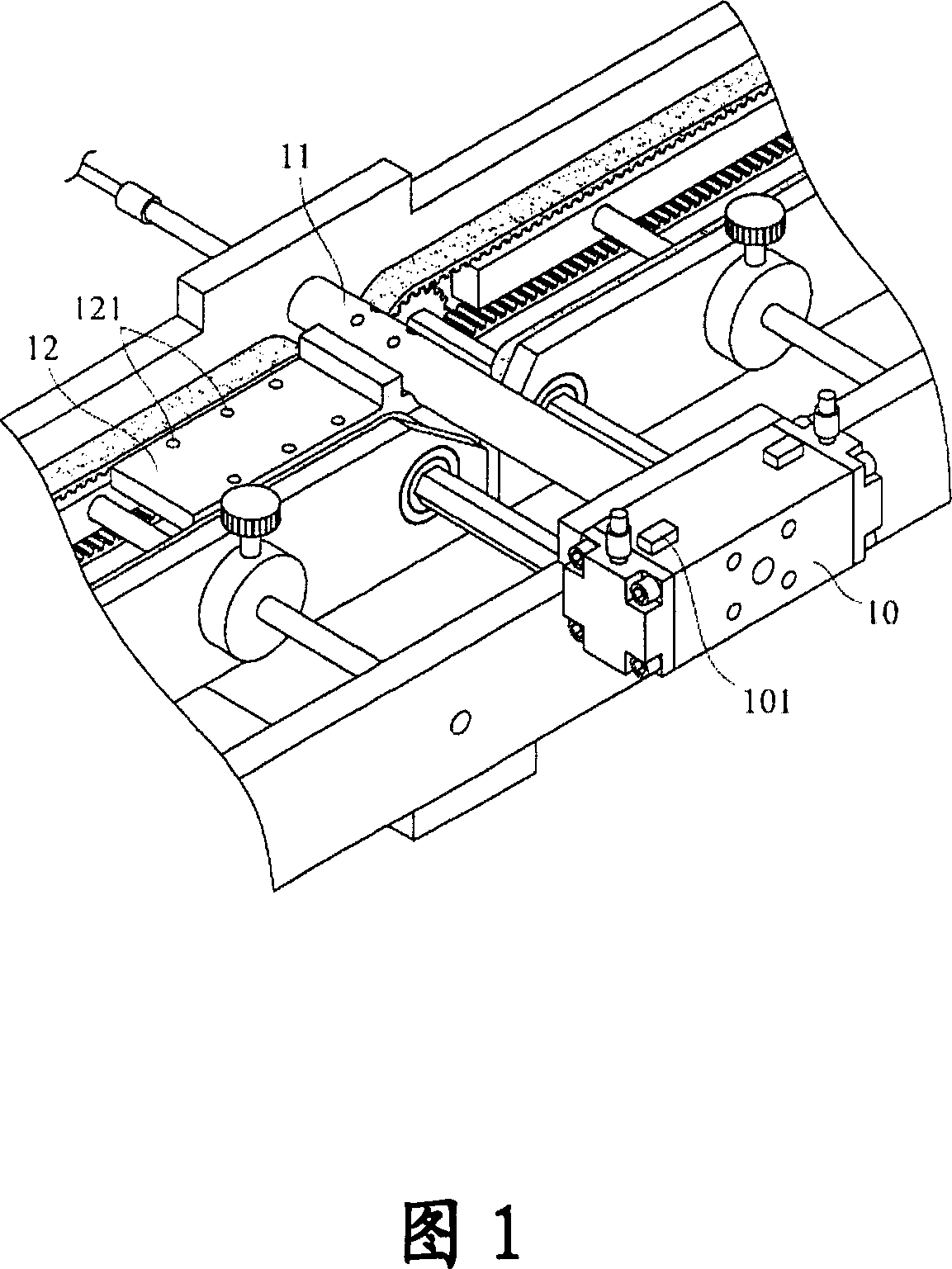

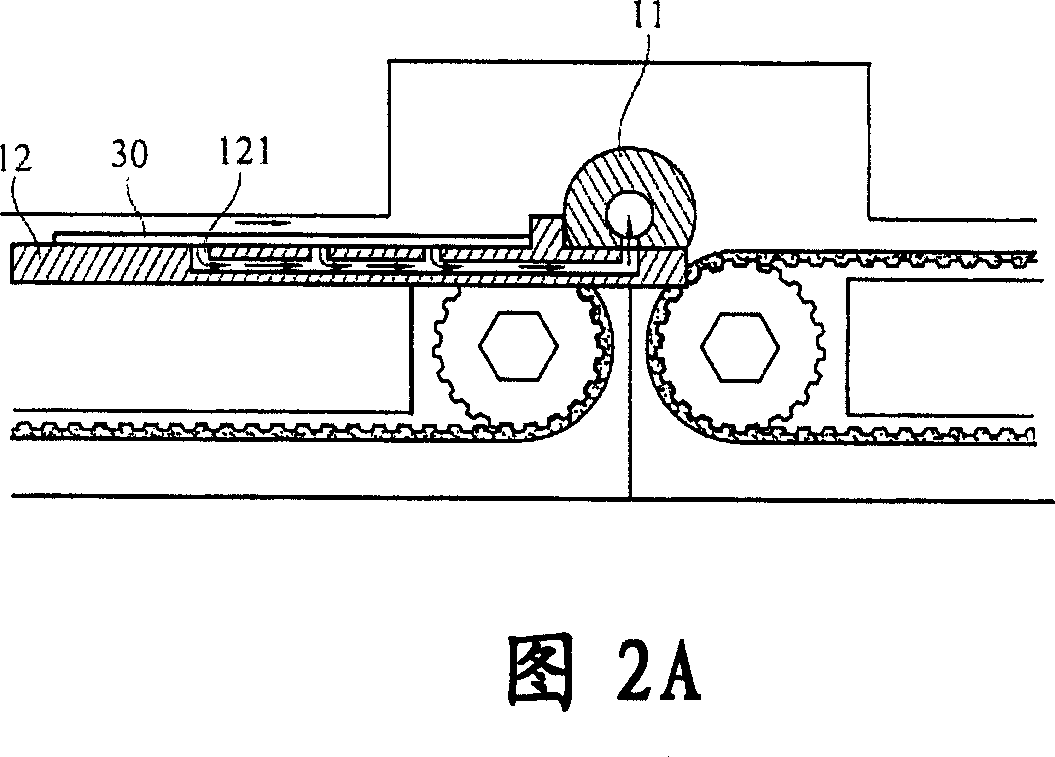

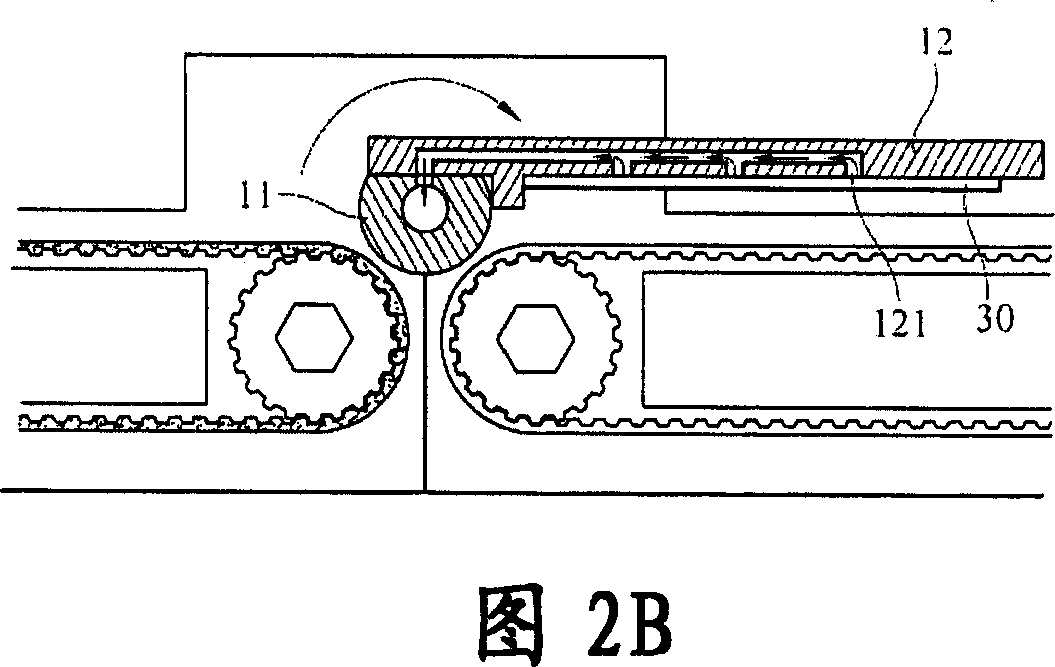

[0038] The preferred embodiments of the present invention and their effects are described as follows in conjunction with the drawings.

[0039] As shown in FIG. 5 and FIG. 6 , a flipping device 40 is disclosed for the present invention.

[0040] The turning device 40 includes: a bracket 41 , a plurality of clamping arms 42 , a clamping unit 43 , a transmission mechanism 44 , a turning mechanism 45 , and a control device 46 .

[0041] The bracket 41 is used for lifting and lowering, and a horizontal rail 411 is provided on the bracket 41 .

[0042] A plurality of clamping arms 42 are located on both sides of the support 41. The clamping arms 42 move up and down along with the support 41, and move laterally along the track 411 on the support 41, and there is a housing between the multiple clamping arms 42. There is room for the panel 50 to be placed.

[0043] The clamping unit 43 is located at one end of the clamping arm 42 , and the clamping unit 43 has an upper jaw 431 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com