Apparatus for the transport of web-like material

A technology of width and control device, which is applied in the directions of folding thin materials, transportation and packaging, winding strips, etc., and can solve the problems of damage to the pressure roller and wear of the pressure roller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

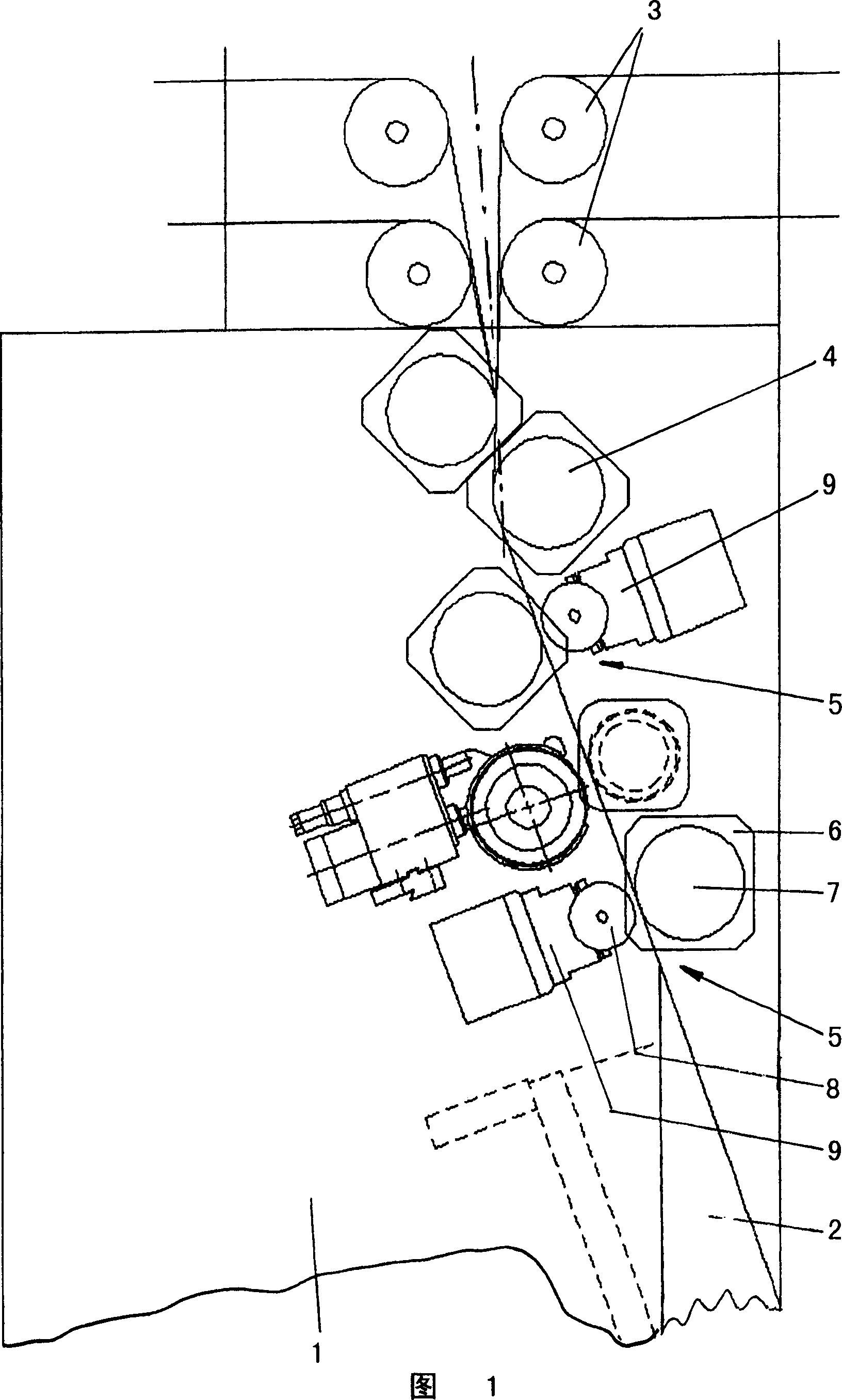

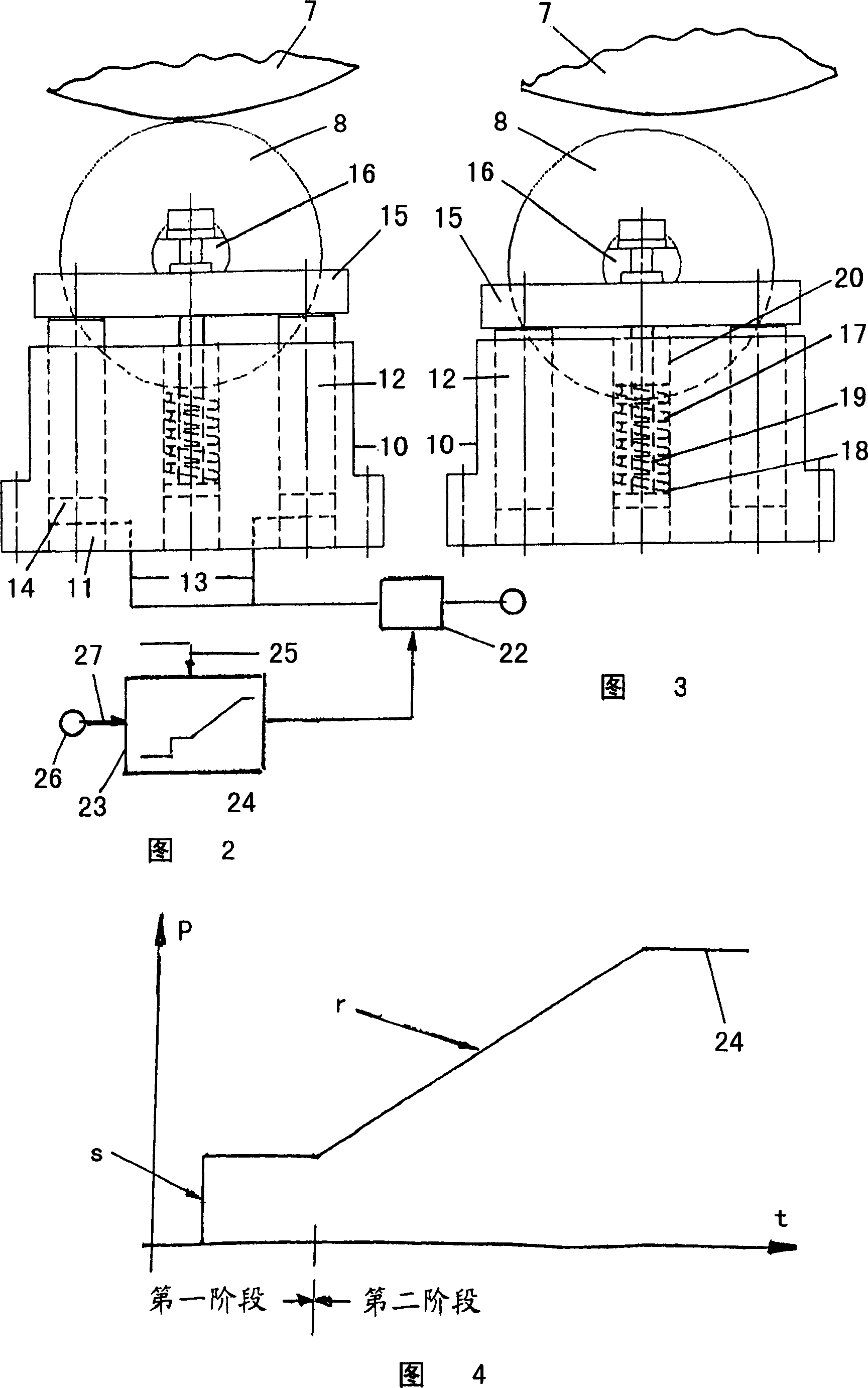

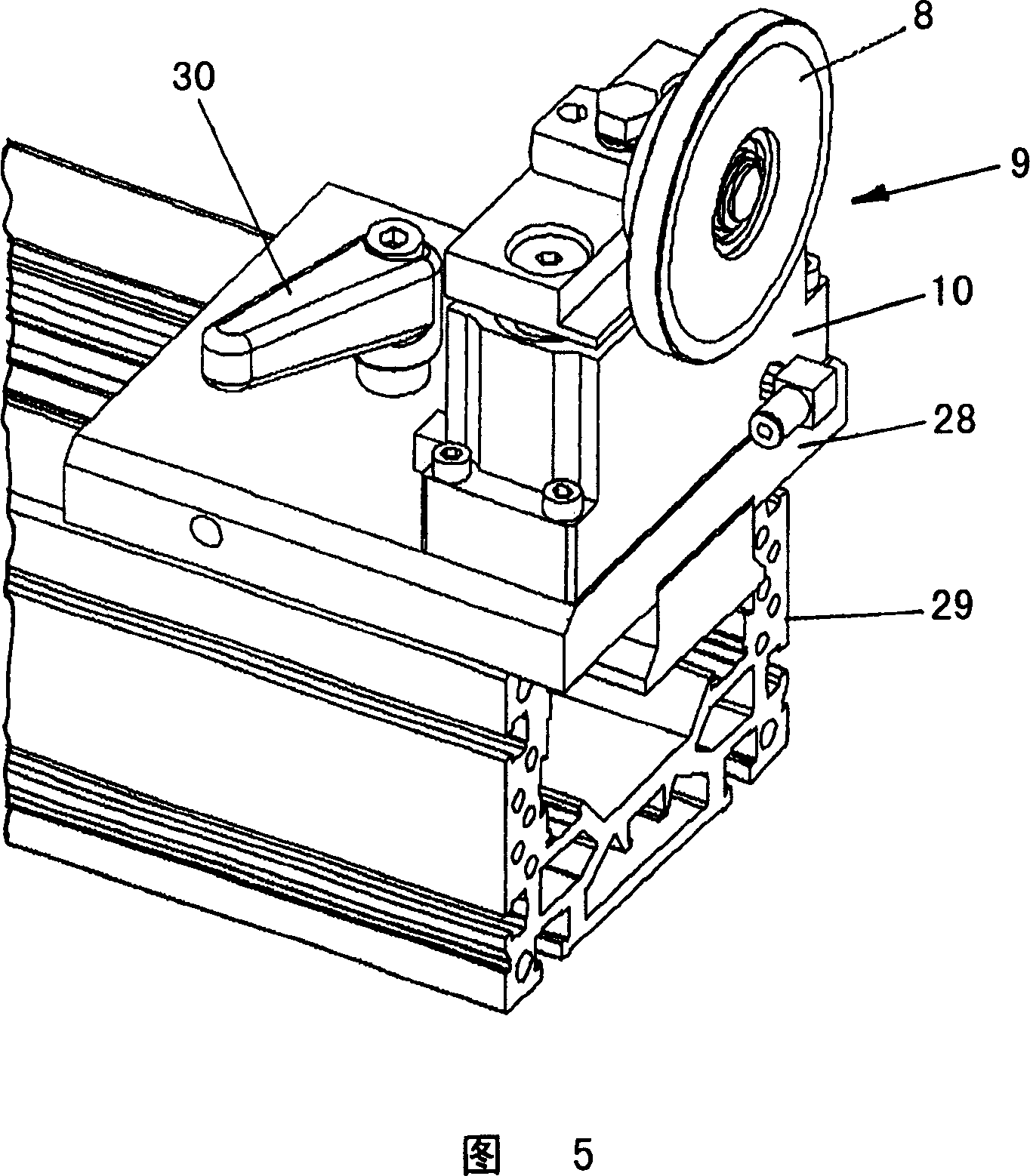

[0018] FIG. 1 shows a folding former 2 arranged in the upper region of the upper part 1 of a folding mechanism, to which a web is fed, which consists of a plurality of webs stacked one above the other, The panels come from an upstream printing press, not shown here in detail. For this purpose, the individual webs coming from the printing press run over a so-called guide wire consisting of a plurality of feed rollers 3 , behind which guide rollers 4 and folding devices 5 are arranged. The folding device 5 includes a folding nip roller 7 that is driven continuously over the entire machine width by means of an associated drive motor 6 and a pressure roller 8 (roller) that can be attached to the folding nip roller. ). The pressure roller 8 is mounted in a freely rotatable manner and is driven solely by friction.

[0019] The pressure rollers 8 can be in contact with the respective associated folding nip rollers 7 or can be cut off from them. All or selected pressure rollers 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com