Printing ink and phosphor slurry composition, printer and plasma display panel using the same, and method of manufacturing the same

A technology for printing inks and display panels, which is applied to printing machines, rotary printing machines, lithographic rotary printing machines, etc., and can solve the problems of difficulty in manufacturing slurry with good thixotropy, delay in development, cost and time loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The preferred embodiments of the present invention will now be described in detail, examples of which are shown in the accompanying drawings. Wherever possible, the same reference numerals will be used in these figures to denote the same or similar parts.

[0053] First, the printing ink according to the present invention will be explained in detail.

[0054] In one embodiment, the printing ink may include a viscosity modifier.

[0055] The viscosity modifier is an additive capable of adjusting the viscosity of the printing ink according to the magnitude of the stress applied to the printing ink. The viscosity modifier includes a thixotropic agent and a dilatant agent.

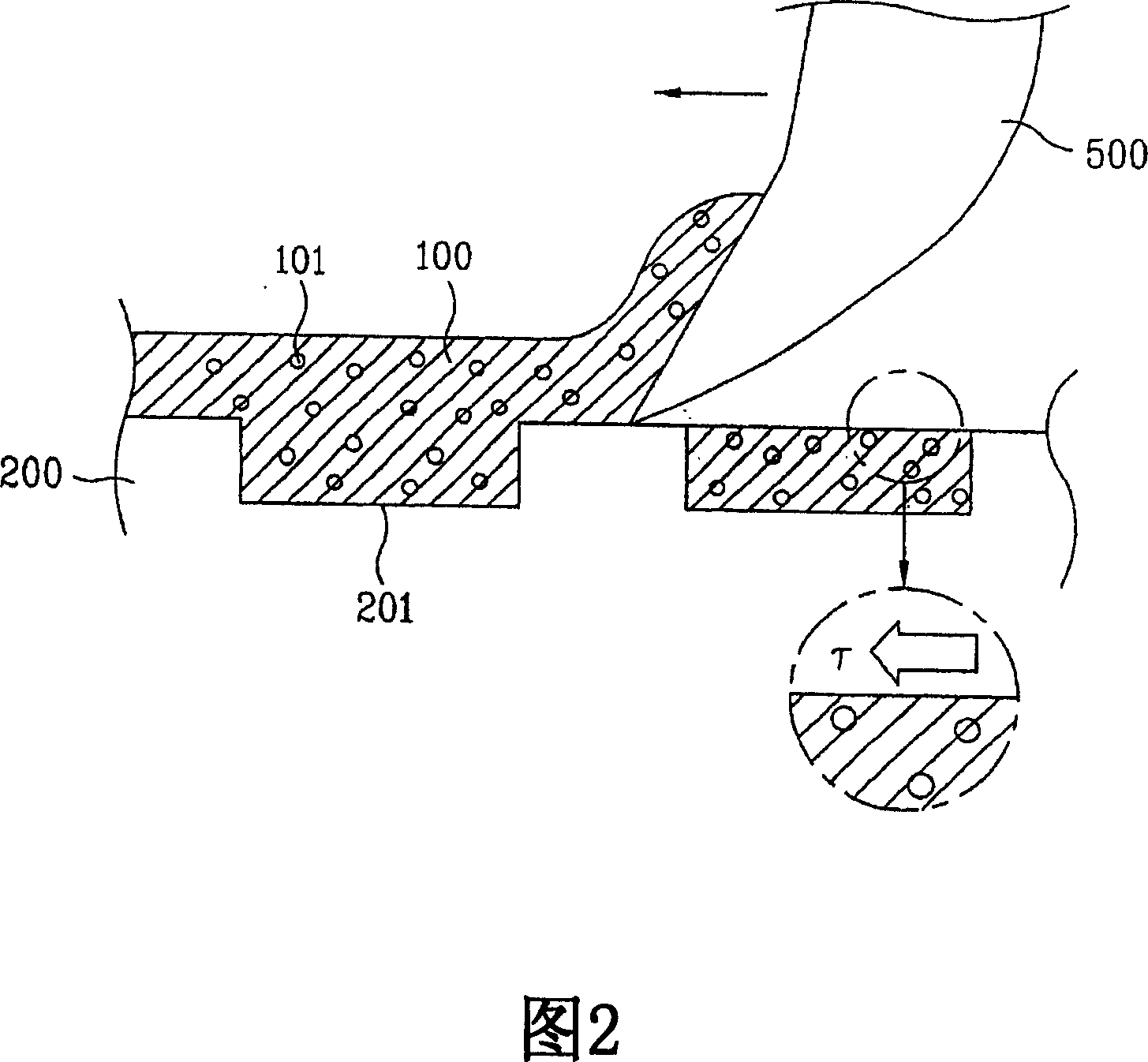

[0056] Thixotropy is a physical property in which when stress acts on a fluid, the viscosity of the fluid decreases, and as a result the fluid becomes a gel phase, and when the stress is removed from the fluid, the viscosity of the fluid increases , The structure is that the fluid becomes a sol phase. In ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com