Slide fastener slider with automatic locking device

An automatic locking and zipper technology, applied in the field of zipper sliders, can solve problems such as damage, small gap between locking claws, and inability to fully exert the locking function of the slider.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

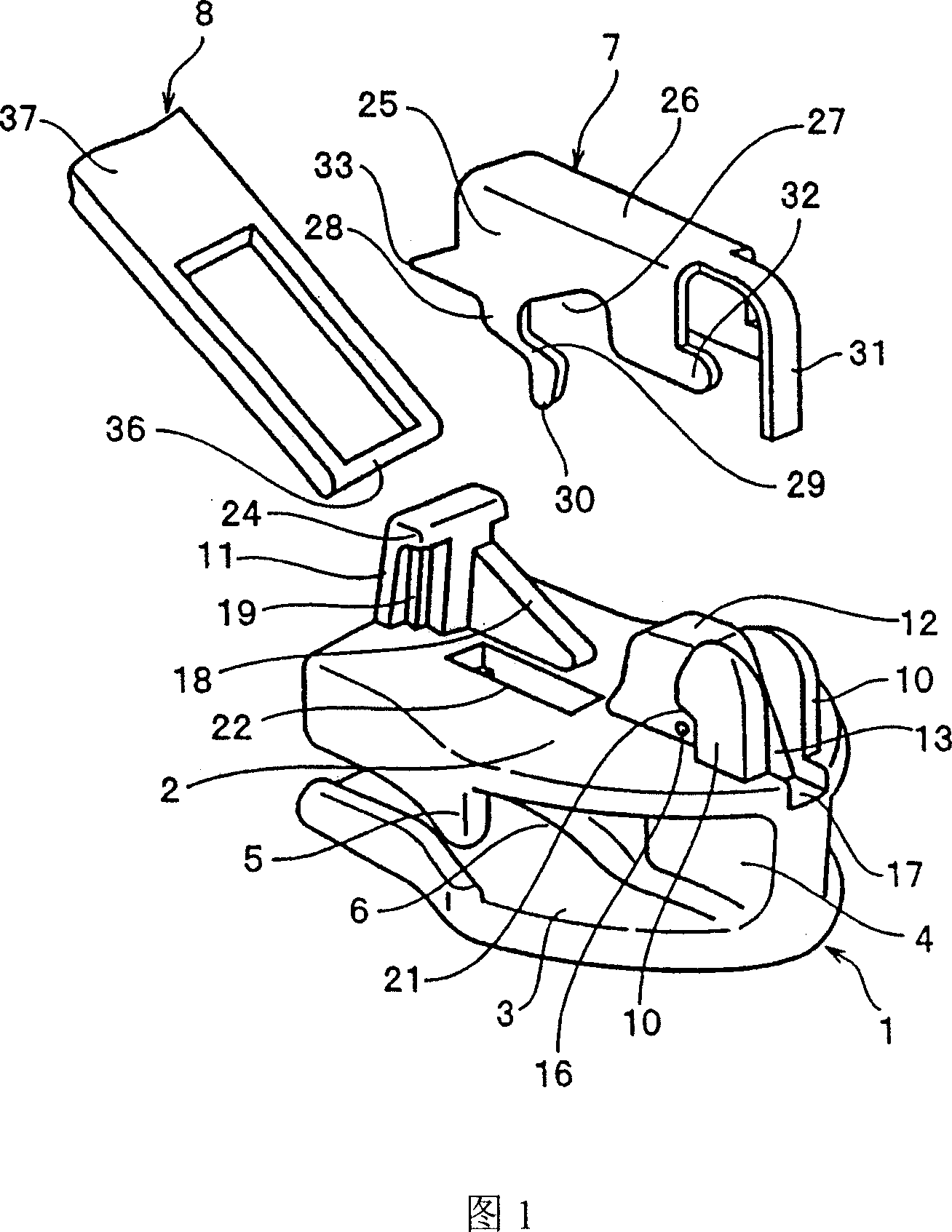

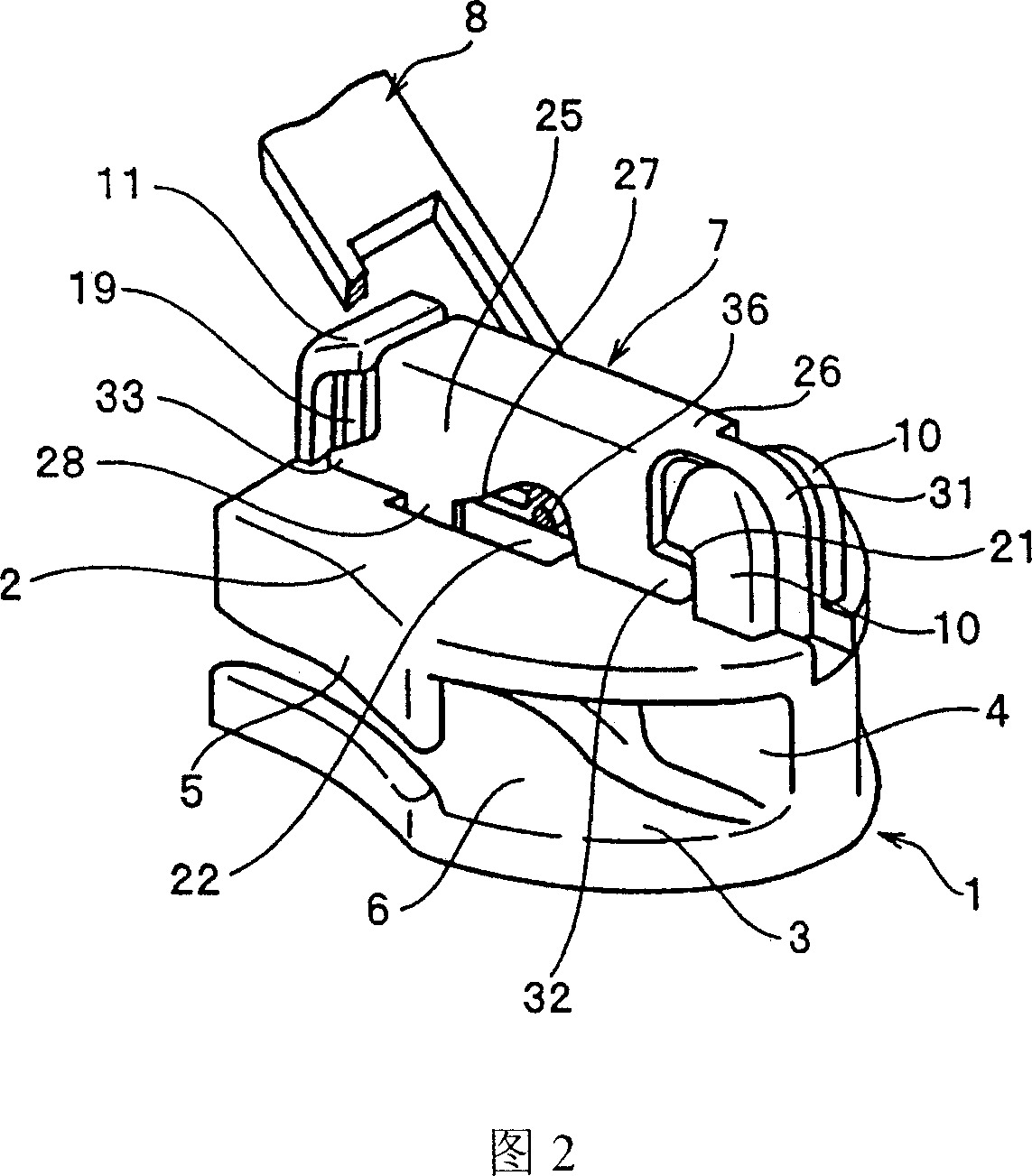

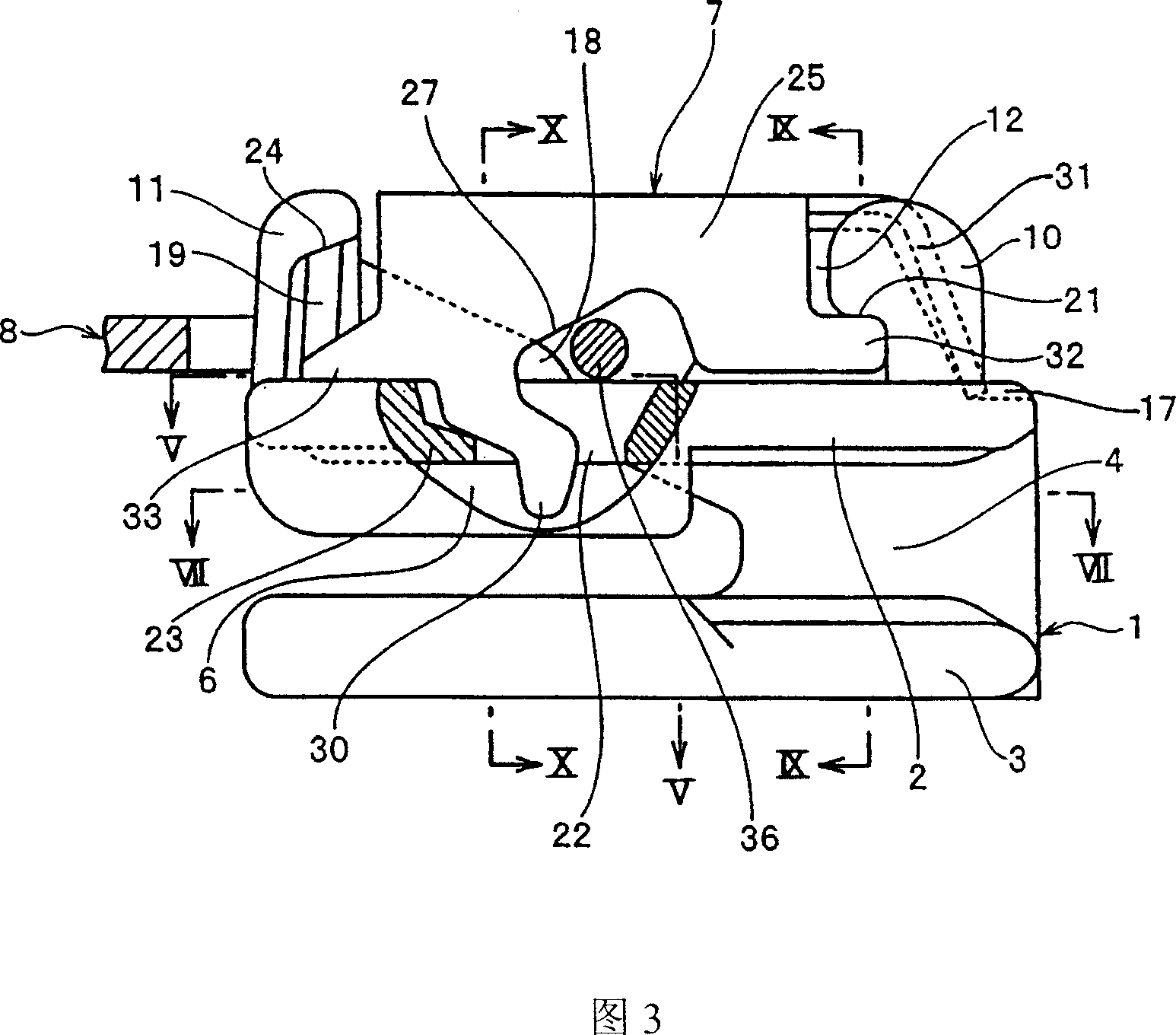

[0040] In the zipper slider with automatic locking device according to the first embodiment shown in FIGS. 7 is formed by stamping steel sheets. The slider with an automatic locking mechanism includes three parts, namely, a main body 1 , a cover 7 and a pull tab 8 . The cover 7 is equipped with locking claws 30 as a locking mechanism, and by operating the pull tab 8, the locking claws 30 can be inserted between the left and right zipper elements 40 arranged in a straight line. A pull tab 8 prepared by a user may be used as the pull tab 8 used here. Therefore, the slider with the automatic locking device can be easily assembled by hand.

[0041] As shown in FIG. 1 , in the slider body 1 , the upper wing plate 2 and the lower wing plate 3 are connected with rhombus blocks, and flanges 5 are formed on two side edges of the upper wing plate 2 . The flange 5 can guide the zipper element 40 on the side edge of the zipper tape 39, the core cord 45 is sewn in the zipper tape 39 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com