Chucking mechanism of dynamic clamp head capable of not damaging tube

A clamping mechanism and power tong technology, applied in the field of power tongs, can solve the problems of accelerating galvanic corrosion, affecting the service life of the pipe body, and damaging the pipe body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

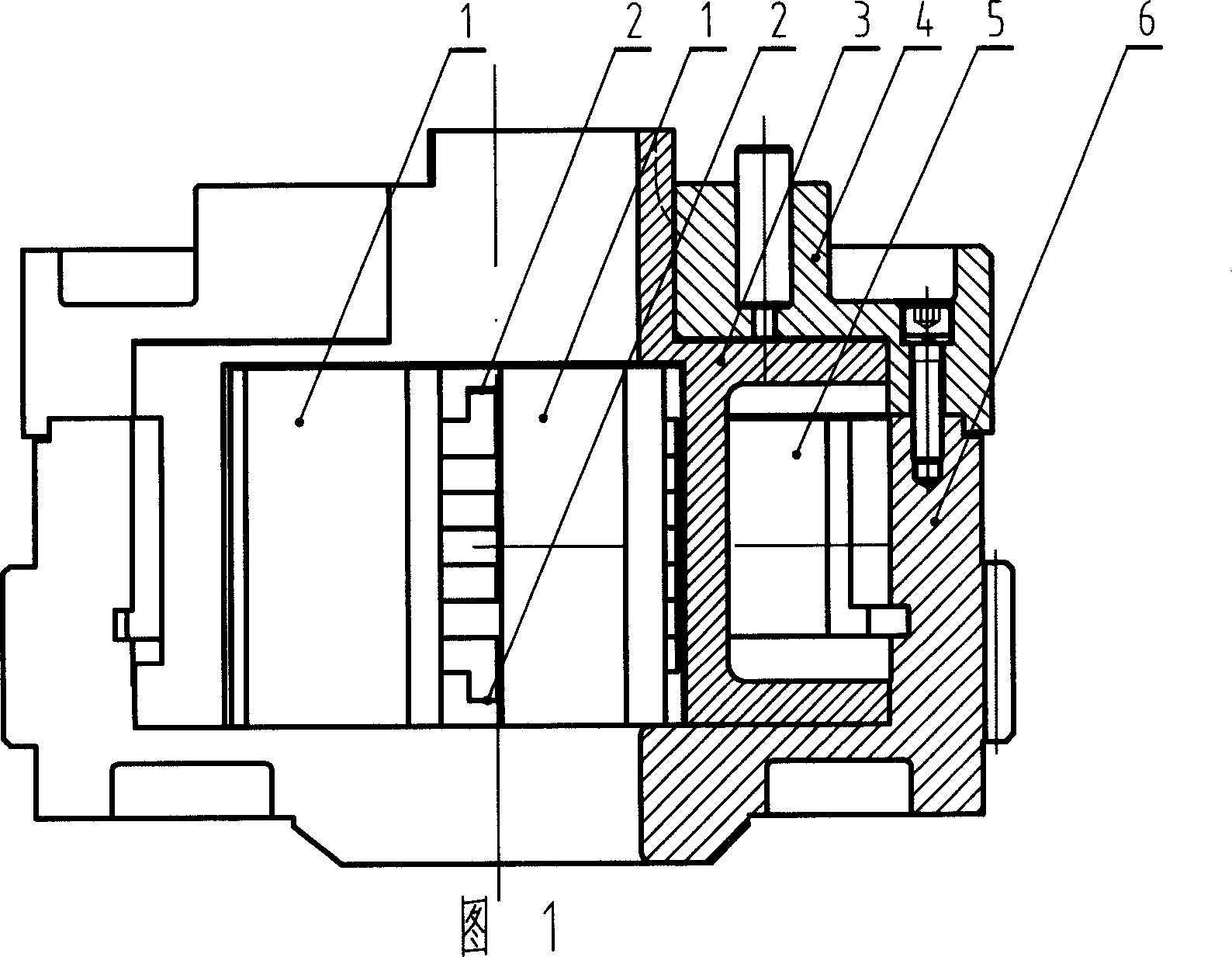

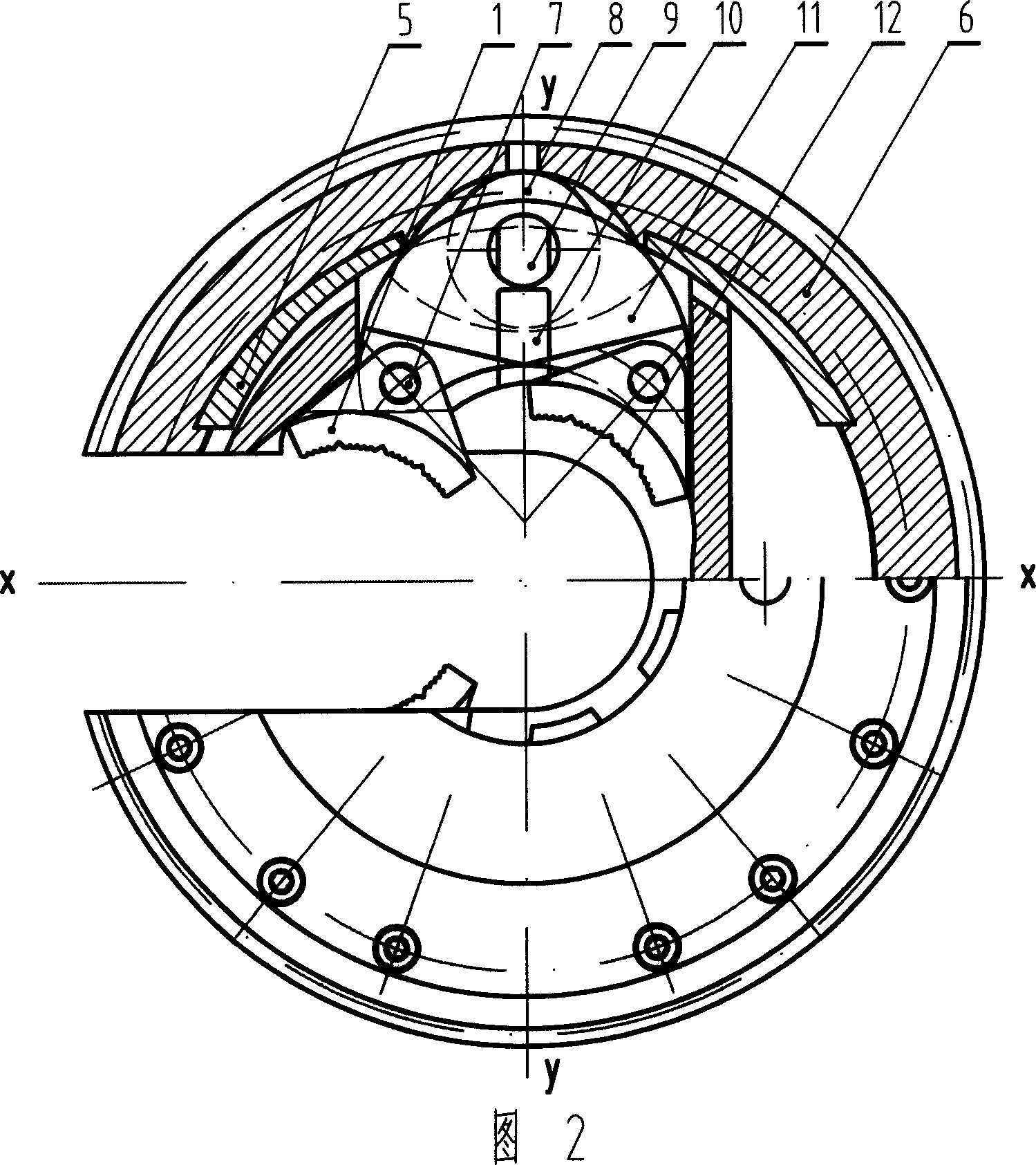

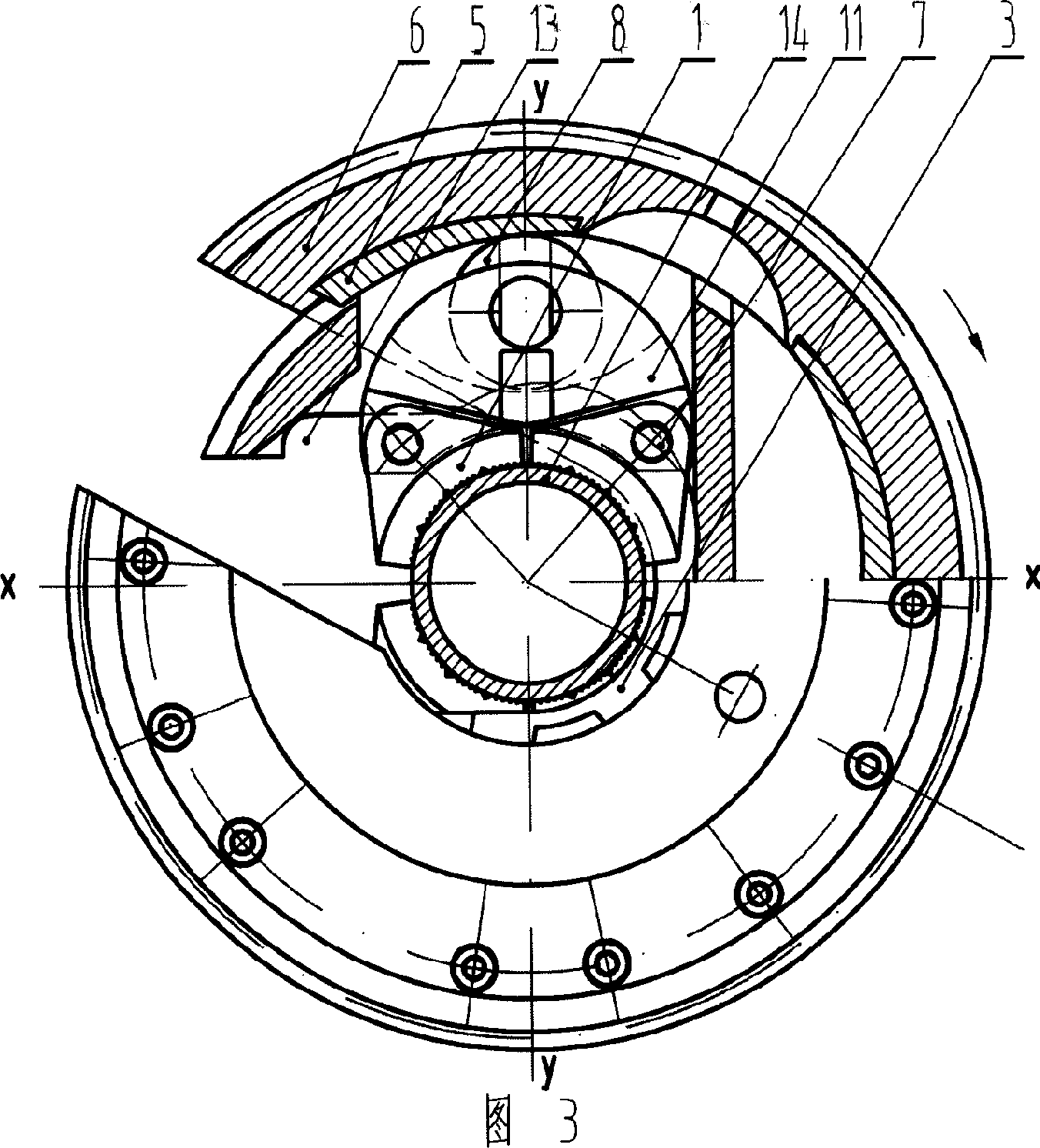

[0012] As shown in Figures 1 and 2, the technical solution of the present invention is: a clamping mechanism of a power pliers head that does not damage the pipe body. , jaw plate 11, jaw plate roller 8, roller shaft 9, inner curved tooth plate 1, tooth plate rotating shaft 7, the inner side of the open gear 6 has an axial dovetail groove, the inner curved slope plate 5 is embedded in it, and the jaw plate frame 3 Located inside the open gear 6, there are square holes for installing the jaw plate 11 on both sides of the symmetrical opening. There are guide grooves 2 on the upper and lower sides of the square hole on the y-coordinate axis. The protruding guide rail 10 can slide radially and centripetally along the upper and lower guide grooves 2 of the jaw plate frame 3. There is a shaft hole on its symmetrical center line, and the roller shaft 9 is installed in it. The roller 8 is located between the two shaft holes and can surround The roller shaft 9 rotates, and the two ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com