Porous particulate material for fluid treatment, cementitious composition and method of manufacture thereof

A technology of porous particles and granular materials, applied in the field of terracotta cementitious compositions and similar, porous granular materials of fluids, and cementitious compositions, which can solve the problems of undisclosed cement, sodium reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

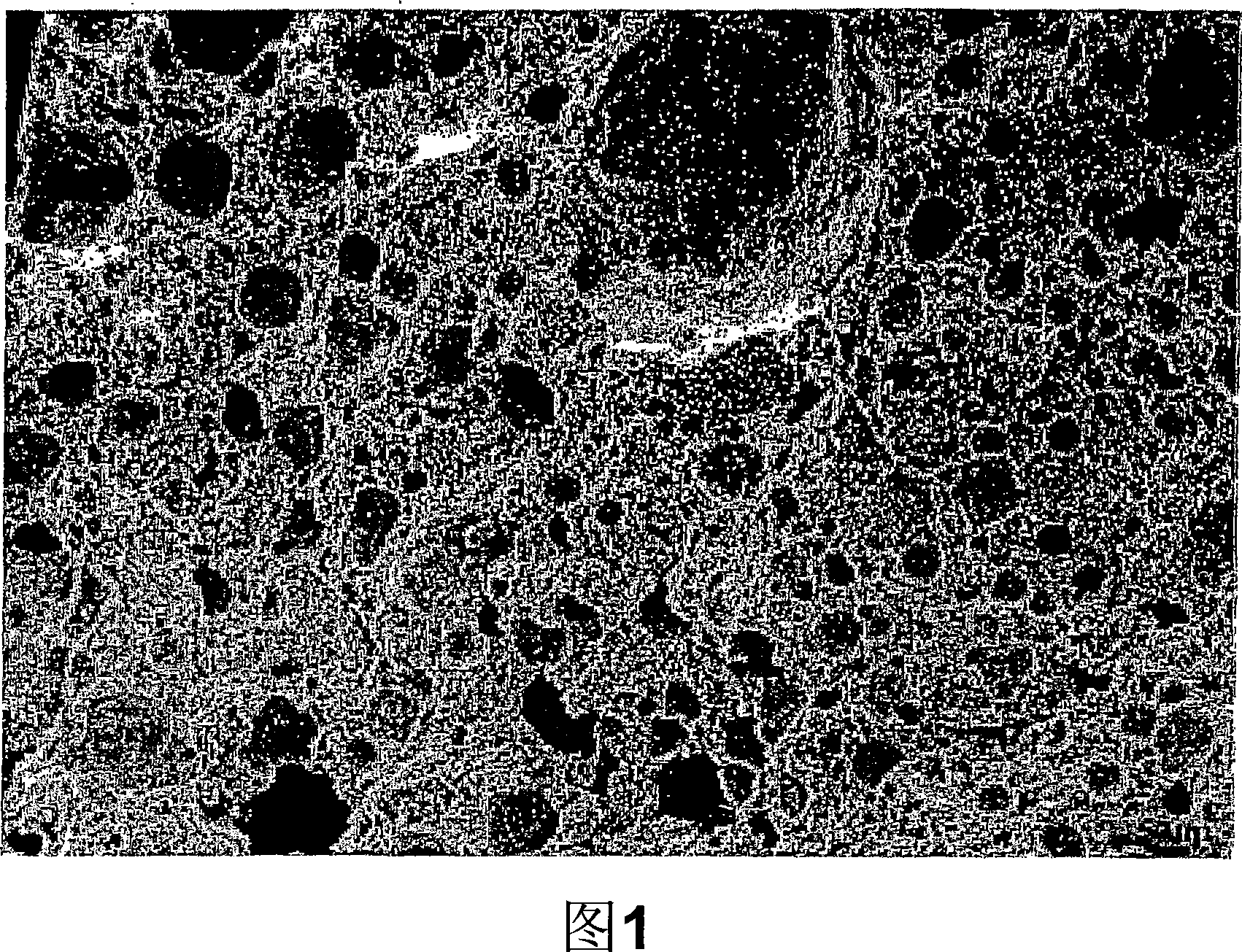

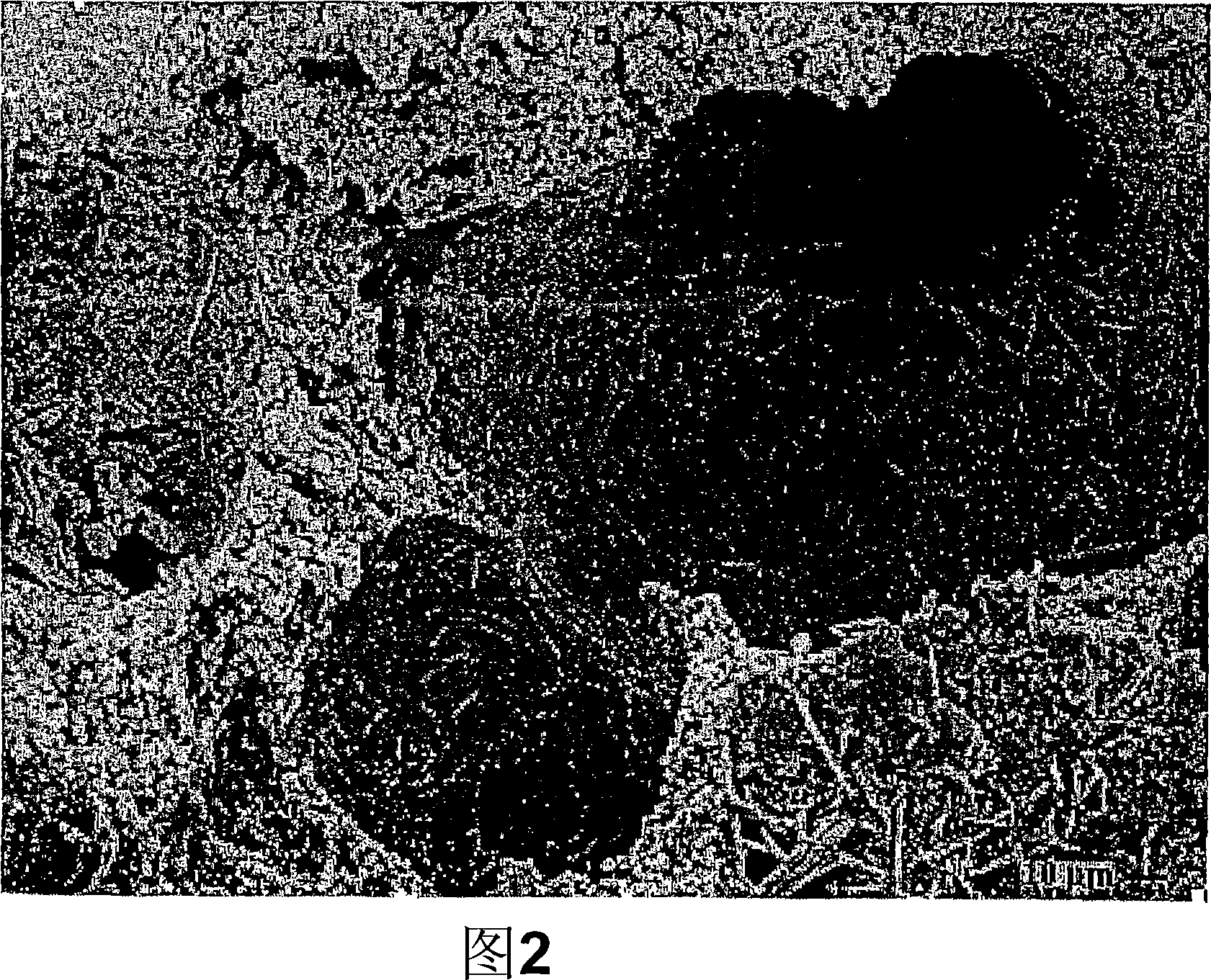

[0257] Example 1: Scanning Electron Microscopy Study of the Pores in the Resulting Agglomerates

[0258] Two pellets were made using the following methods.

[0259] Pellet 1 was made by mixing the following components to form a slurry:

[0260] 80g processed red mud

[0261] 4g slaked lime

[0263] 2g HPMC plasticizer / polymerizer,

[0264] 15g Portland cement;

[0265] 8g dry component quartz sand

[0266] 70mL water,

[0267] 8mL 3% HO 2 o 2 ,and

[0268] 0.22mL 1.5M HO 3 PO 4

[0269] The above components were mixed in a shear mixer for 1 minute. The wet slurry was poured into molds with a height-to-diameter aspect ratio of 3.5:1, capped tightly, and cured for 28 days.

[0270] Pellet 2 was made by mixing the following components to form a slurry:

[0271] 70g processed red mud

[0272] 2g HPMC plasticizer,

[0273] 15g Portland cement,

[0274] 13g quartz sand

[0275] 70mL water,

[0276] 0.8mL 3% HO 2 o 2 ,and

[0277] 0....

Embodiment 2

[0281] Example 2: Treatment of metal-rich tanning wastewater using a column composed of porous pellets

[0282] Referring to FIG. 7, a schematic diagram of the laboratory setup used to obtain the results of Example 2 is shown. This test used the pellet 1 given in Example 1 above, which was slightly crushed and sieved to obtain material in 4 particle size ranges: 250 μm to 500 μm, 500 μm to 750 μm, 750 μm to 1000 μm, and 1000 μm to 2000 μm. A pellet mixture of 4 particle sizes of 25% each was made to provide the filtration / reaction column (10). Three filtration / reaction columns (10, 20, 30) were constructed using polycarbonate tubing with an internal diameter of 44 mm. One end of each column (10, 20, 30) was closed and filled with a 10 cm long section of coarse sand and gravel mixture (12), geotextile wadding, treated red mud pellets as a prefilter (14), another geotextile wadding (16), another 10 cm long coarse sand and gravel to hold the treated red mud pellets (14) in plac...

Embodiment 3

[0285] Example 3: Instructions for Batch Production of Porous Agglomerates in a 4 Cubic Meter Cement Mixer

[0286] Element

[0287] 2000kg A1 treated red mud, sieved to <2mm

[0288] 400kg ordinary Portland cement;

[0289] 250kg finely ground quartz sand;

[0290] 100kg slaked lime, sieved to <1mm;

[0291] 200kg magnesium oxide, sieved to <1mm;

[0292] 50kg hydroxypropyl-methyl-cellulose (HPMC) plasticizer;

[0293] About 2000L water;

[0294] 25L 3% hydrogen peroxide (H 2 o 2 );

[0295] 7L 1.5M orthophosphoric acid (H 3 PO 4 );

[0296] Total dry product weight: 3,000kg

[0297] Gross wet product weight: approx. 2,032kg

[0298] Total wet weight: approx. 5,032 kg (2m 3 )

[0299] It will be appreciated that the dry treated red mud described above may optionally be used. Treated red mud with a moisture content of about 50% can additionally be used, but the amount of water added needs to be reduced in proportion to the water content in the treated red mud. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com