All-purpose house car

A boxcar and car body technology, applied in the field of railway transportation tools and general boxcars, can solve the problems of slow development of railway transportation, low vehicle service life, unsatisfactory overall structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

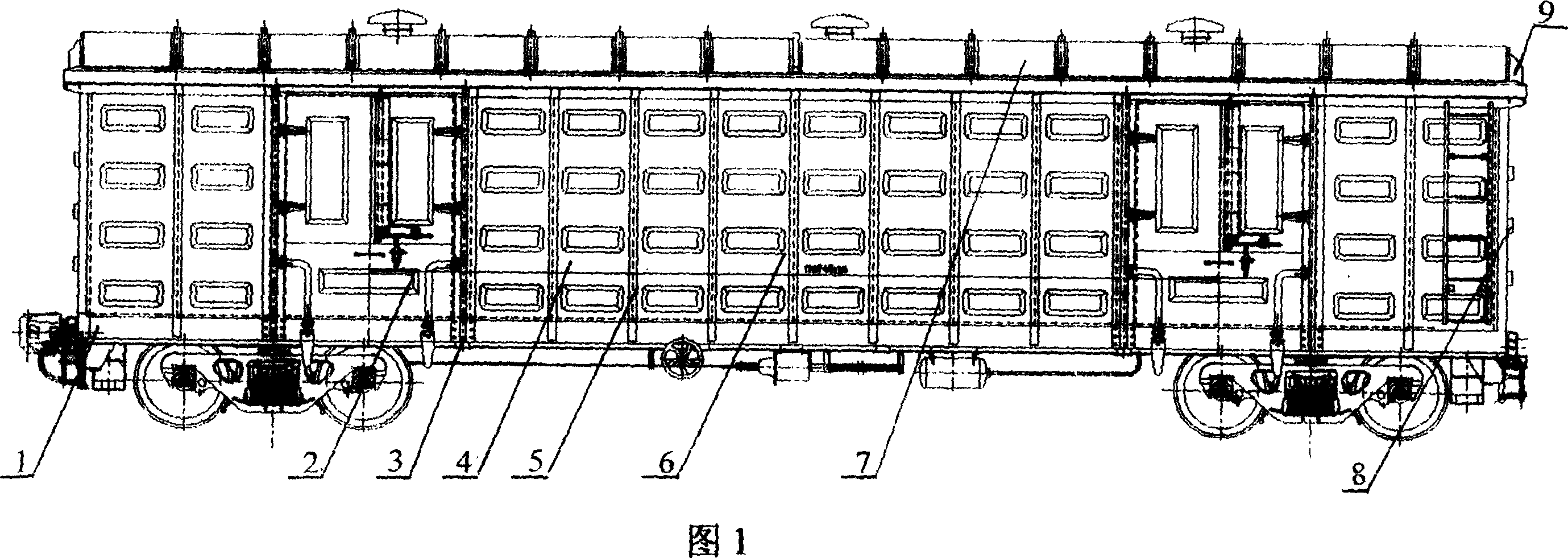

[0019] Referring to the accompanying drawings, the present invention includes a car body, a brake device, a coupler buffer device and a bogie, and its key technology is that the car body is an all-steel welded integral bearing structure, including an underframe 1, side walls 6, end walls 8 and a roof 7.

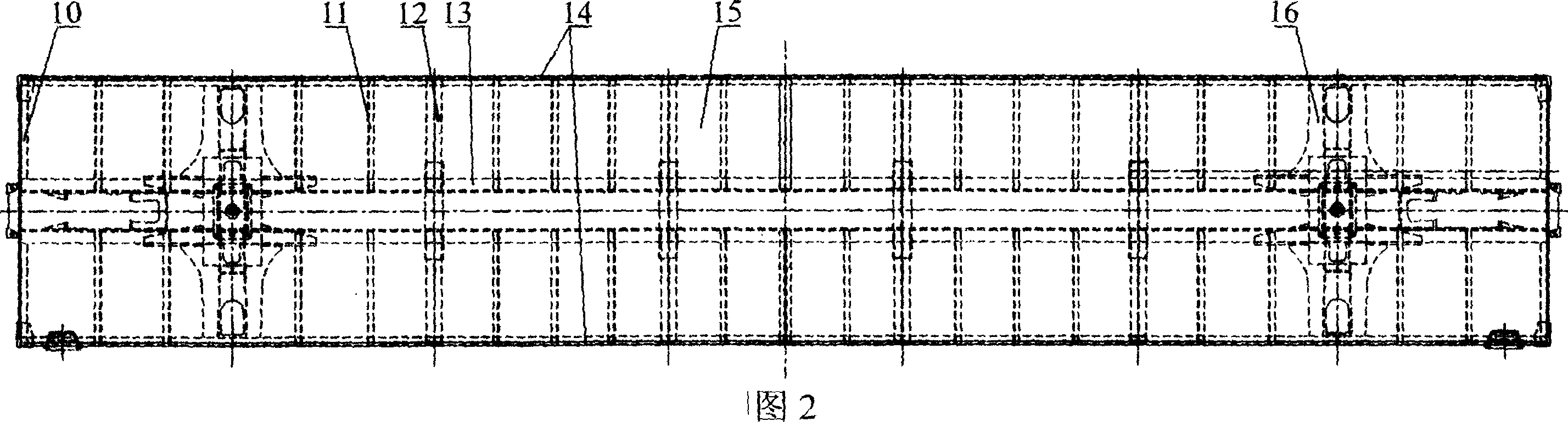

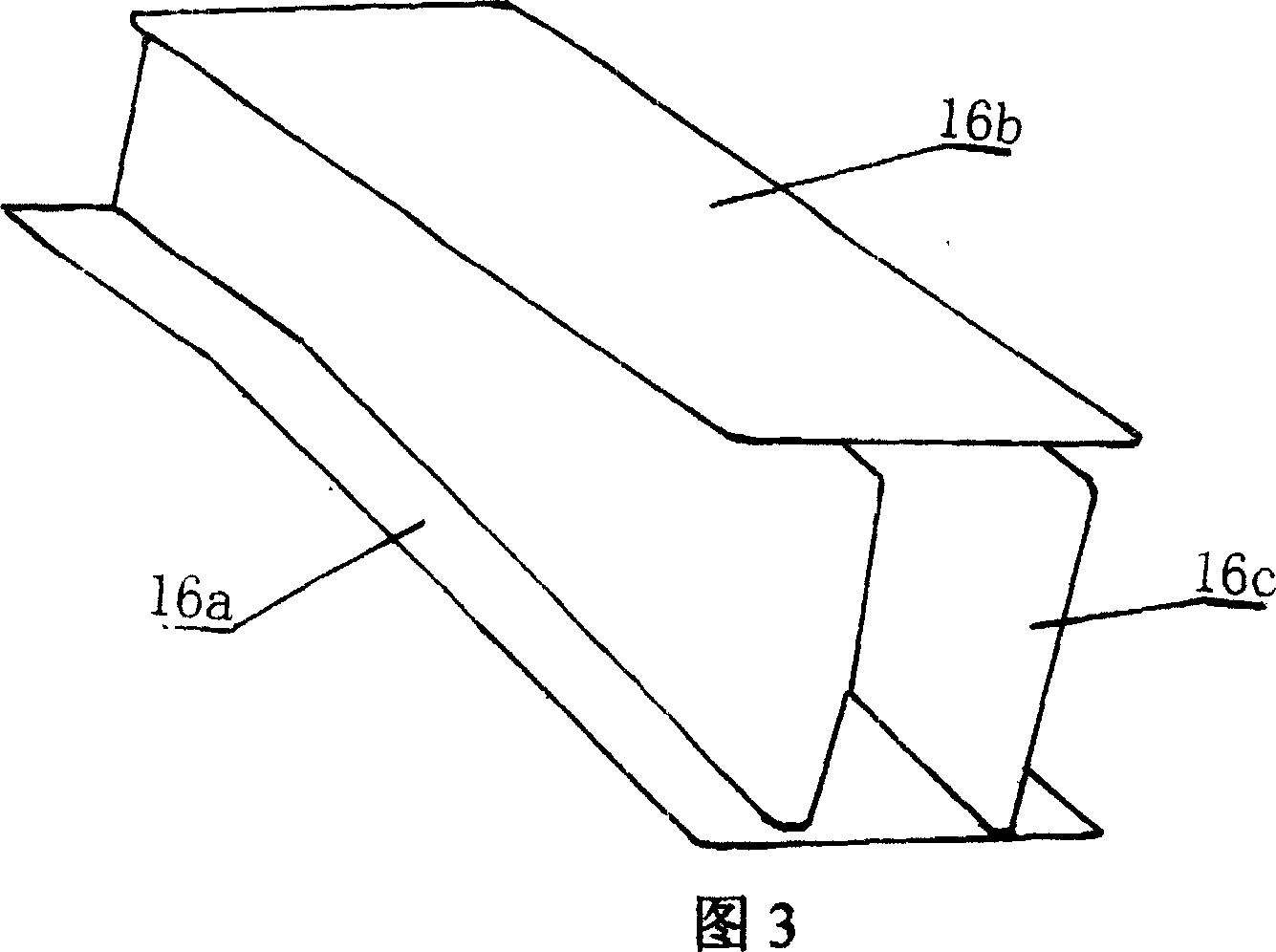

[0020] The underframe 1 includes a center beam 13 , a side beam 14 , a corbel 16 , an end beam 10 and a large beam 12 . The middle beam 13 is assembled and welded by two B-shaped steels, and is located in the middle of the chassis along the longitudinal direction of the chassis; the side beams 14 are parallel to the middle beam 13 and are located on both sides of the chassis; the end beams 10 are located on both sides of the chassis. end; the large beam 12 is welded with a web 12c between the upper cover plate 12b and the lower cover plate 12a to form an I-shaped section beam, which is installed in parallel between the two side beams 14 along the transverse direction of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com