Manufacturing method of optical compensation film, optical compensation film, polarizing sheet and liquid display device

A technology of optical compensation film and liquid crystal display device, which is applied in the direction of optics, polarizing elements, optical elements, etc., can solve the problems of optical unevenness and predict optical unevenness, and achieve the effect of fast response speed and excellent optical compensation function

Active Publication Date: 2010-09-08

FUJIFILM CORP

View PDF37 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In recent years, as the demand for LCD TVs has increased, LCD TVs have grown in size and brightness, but there has been a problem of subtle optical unevenness

In particular, the OCB type liquid crystal display device, which is excellent in animation adaptability, which is an important factor of television, is expected to pose a big problem of optical unevenness because the display principle is a birefringence type.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Login to View More

Abstract

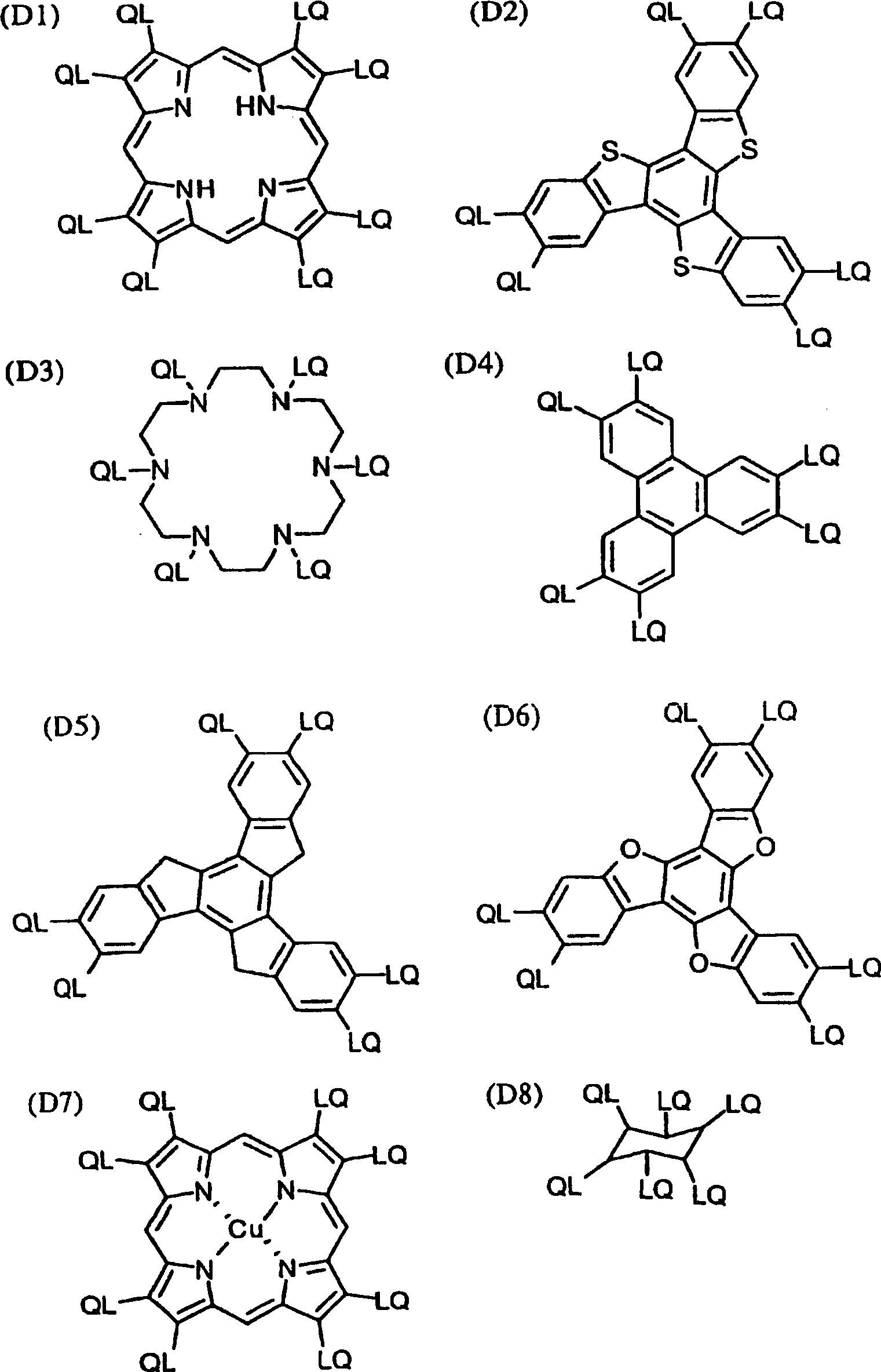

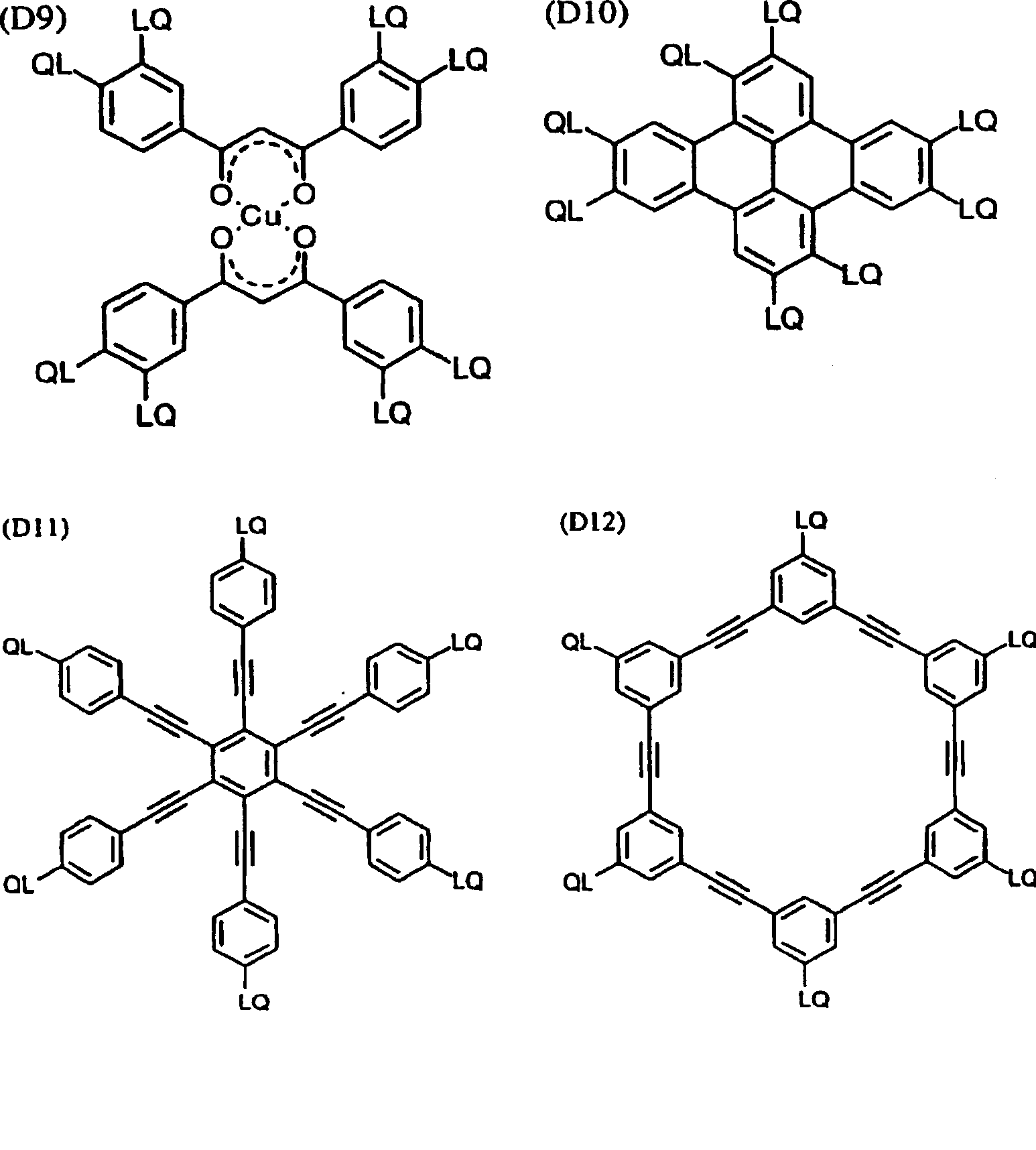

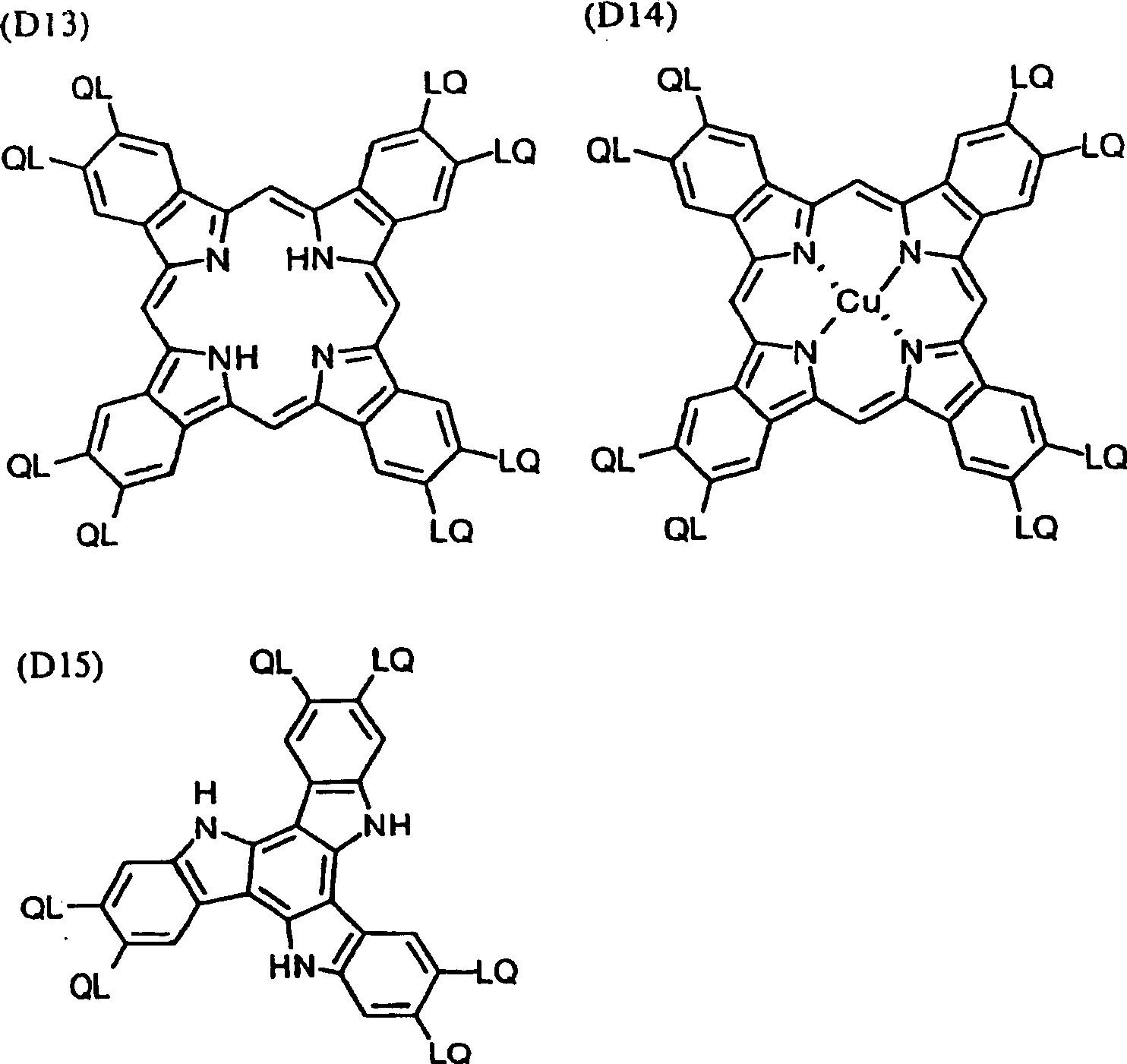

The present invention provided a method for stably and continuously manufacturing an optical compensating film which has a superior optical compensating function for an OCB type liquid crystal display device and also has small optical unevenness, and to provide the optical compensating film obtained by the method, a polarizer using the same, and a liquid crystal display device. Disclosed are the method for manufacturing the optical compensating film having a stage of forming a liquid crystal compound layer by coating a base with coating liquid containing a polymerizable liquid crystal compound, a stage of forming an optical anisotropic layer by aligning the liquid crystal compound after drying the liquid crystal compound layer and then fixing the alignment, and a stage of further heating the optical anisotropic layer at heating temperature of 40 to 150 DEG C for a heating time of 5 to 3,000 seconds after fixing the alignment of the liquid crystal compound, the optical compensating film obtained by the method, the polarizing plate using the same and the liquid crystal display device.

Description

technical field The present invention relates to an optical compensation film having an optically anisotropic layer in which a polymerizable liquid crystal compound is aligned, a method for producing the same, a polarizing plate and a liquid crystal display device using the optical compensation film. Background technique In recent years, optical films having a layer in which a liquid crystal compound is highly oriented and fixed have been used in various applications such as optical compensation films for liquid crystal display devices, brightness enhancement films, and optical compensation films for projection display devices. The development of optically compensating films for devices has attracted attention. Generally, a liquid crystal display device includes a polarizing plate and a liquid crystal cell. In the currently mainstream TN type TFT liquid crystal display device, an optical compensation film is inserted between the polarizing plate and the liquid crystal cell,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G02F1/13363G02B5/30

CPCG02B5/3016G02B5/3041G02B5/3083G02F1/133528G02F1/13363G02B1/14

Inventor 伊藤洋士

Owner FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com