Large axle load bogie

A bogie and large axle load technology, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, to achieve the effects of reduced wheel-rail force, high structural strength, and improved curve passing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

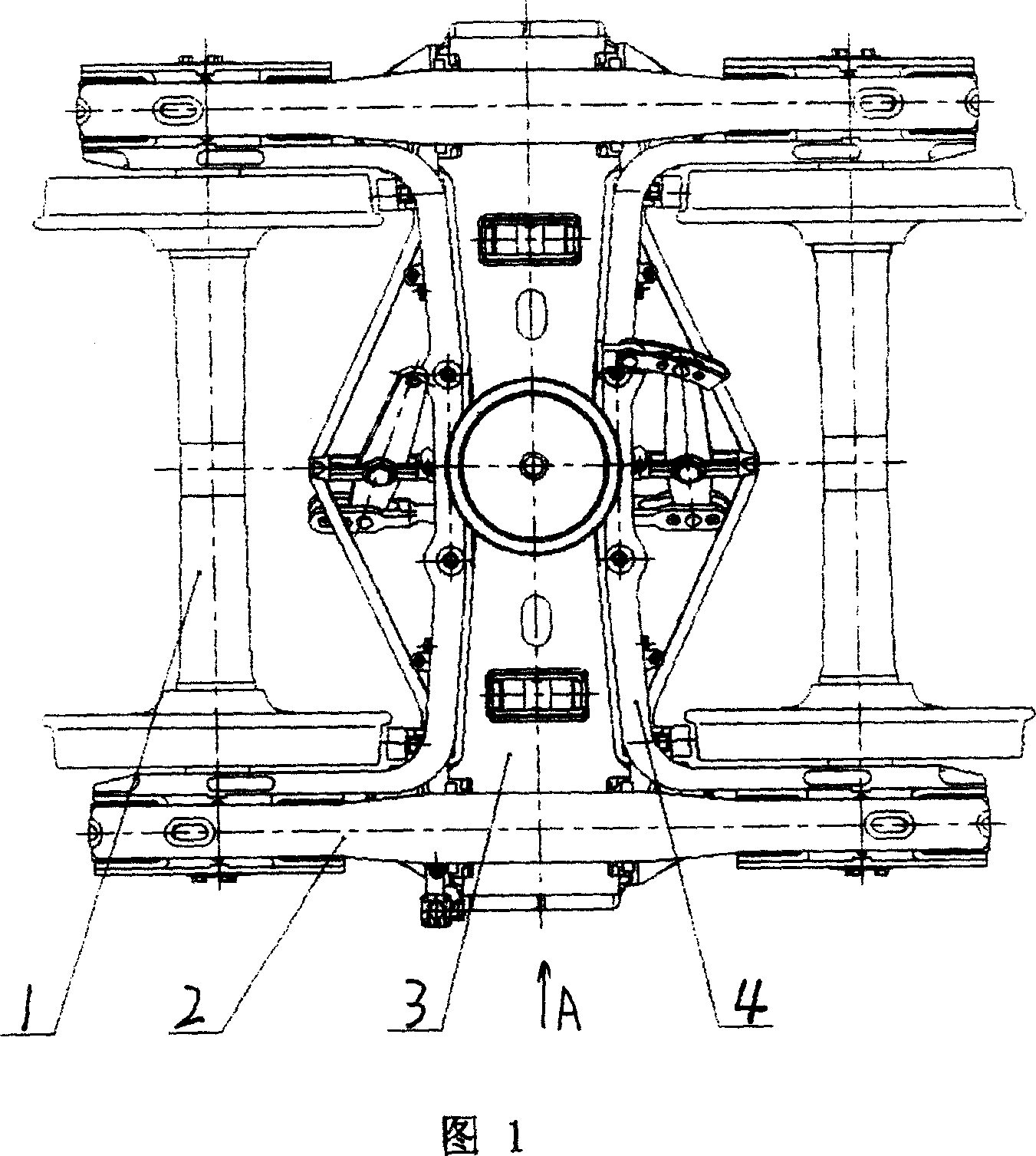

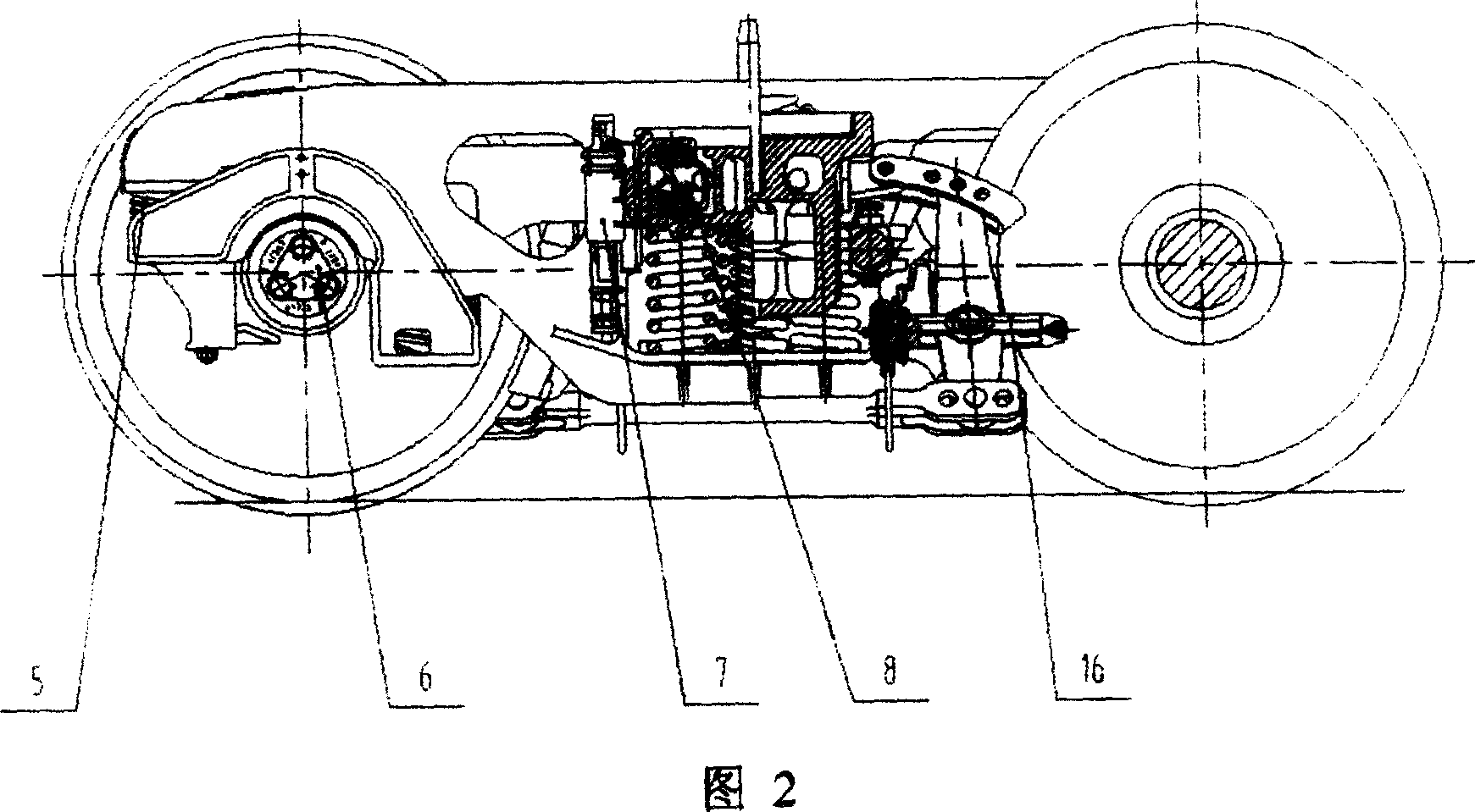

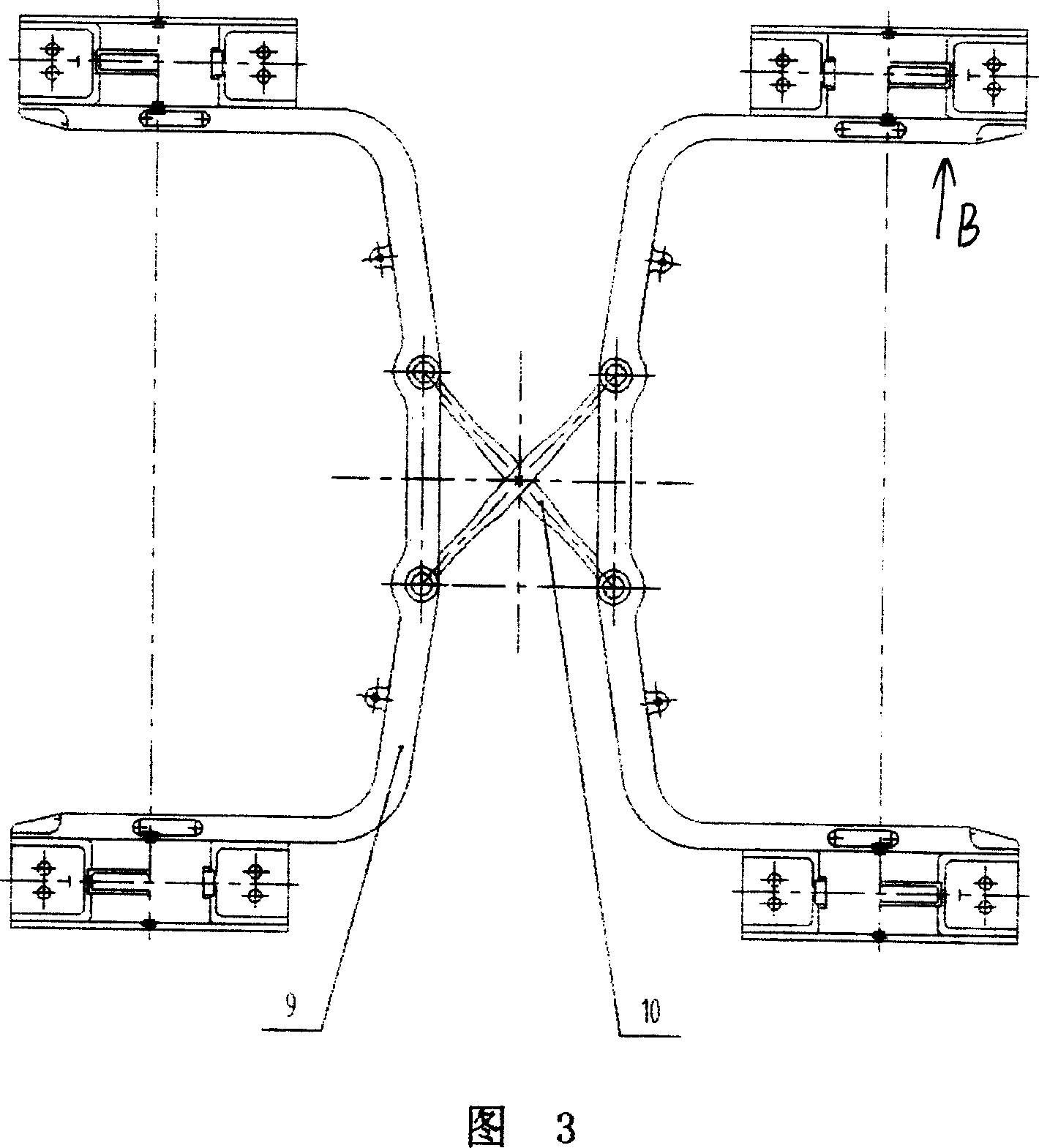

[0022] Referring to the accompanying drawings, the present invention includes a wheel set 1, a side frame 2 and a bolster 3. The wheel set 1 is formed by connecting left and right wheels through an axle, and two adjacent sets of wheels are respectively located on both sides of the bolster 3, forming bogie. The key technology is to install the sub-frame 9 on the bearings 6 at both ends of the axle of the wheel set 1, that is, the two ends of the sub-frame 9 are respectively installed on the bearings 6 at both ends of the axle, and the sub-frame 9 is formed by a tie rod passing through the middle of the bolster 3 10 are connected by pin joints, the sub-frame 9 and the tie rod 10 connected to it form the self-guiding device 4 of the bogie, and the inner sides of both ends of the sub-frame 9 adopt a U-shaped box structure as shown in Figure 4 . The two ends of the sub-frame 9 are fitted with side frames 2, and an elastic device 5 is installed between the side frame 2 and the sub-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com