Combustion device

A combustion device and fuel technology, applied in burners, combustion chambers, combustion methods, etc., can solve the problems of low total air ratio and difficult combustion, and achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

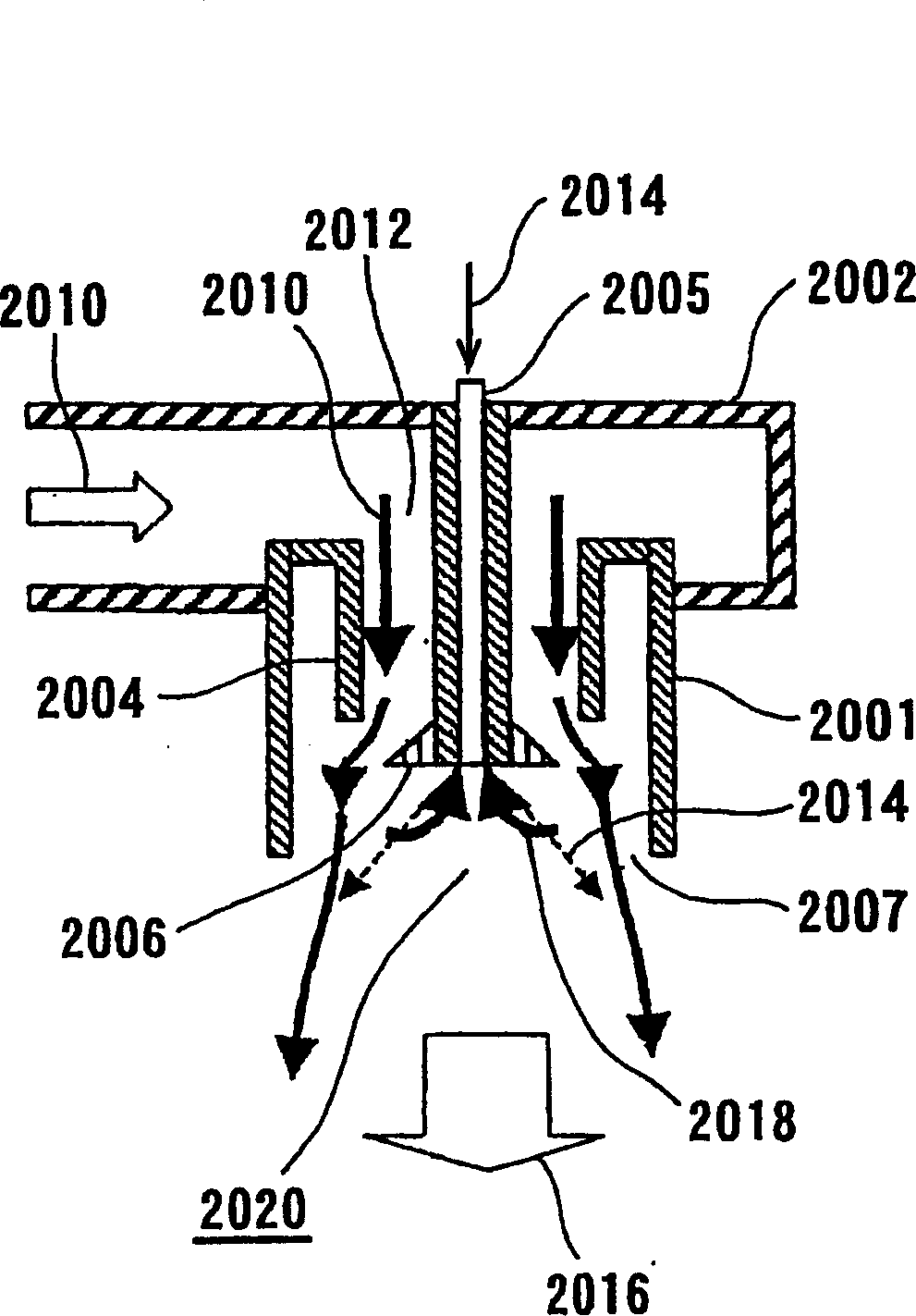

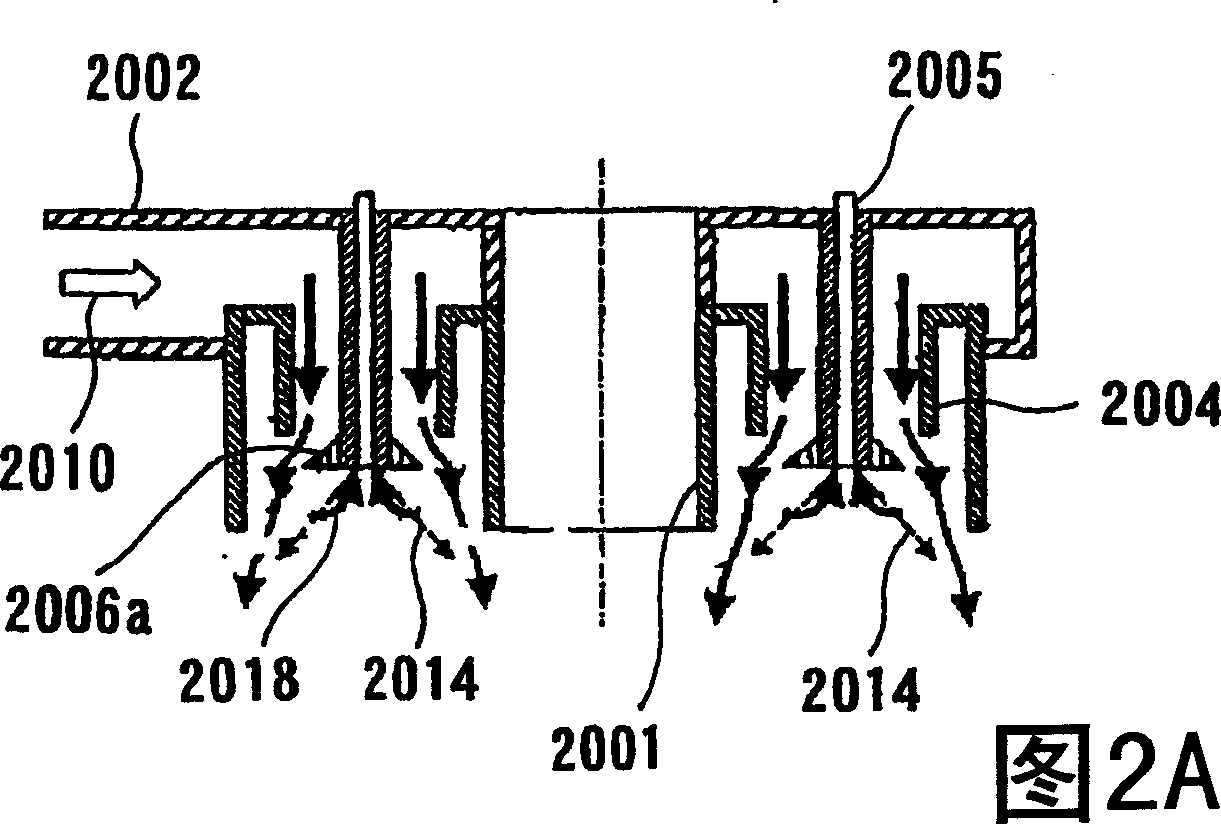

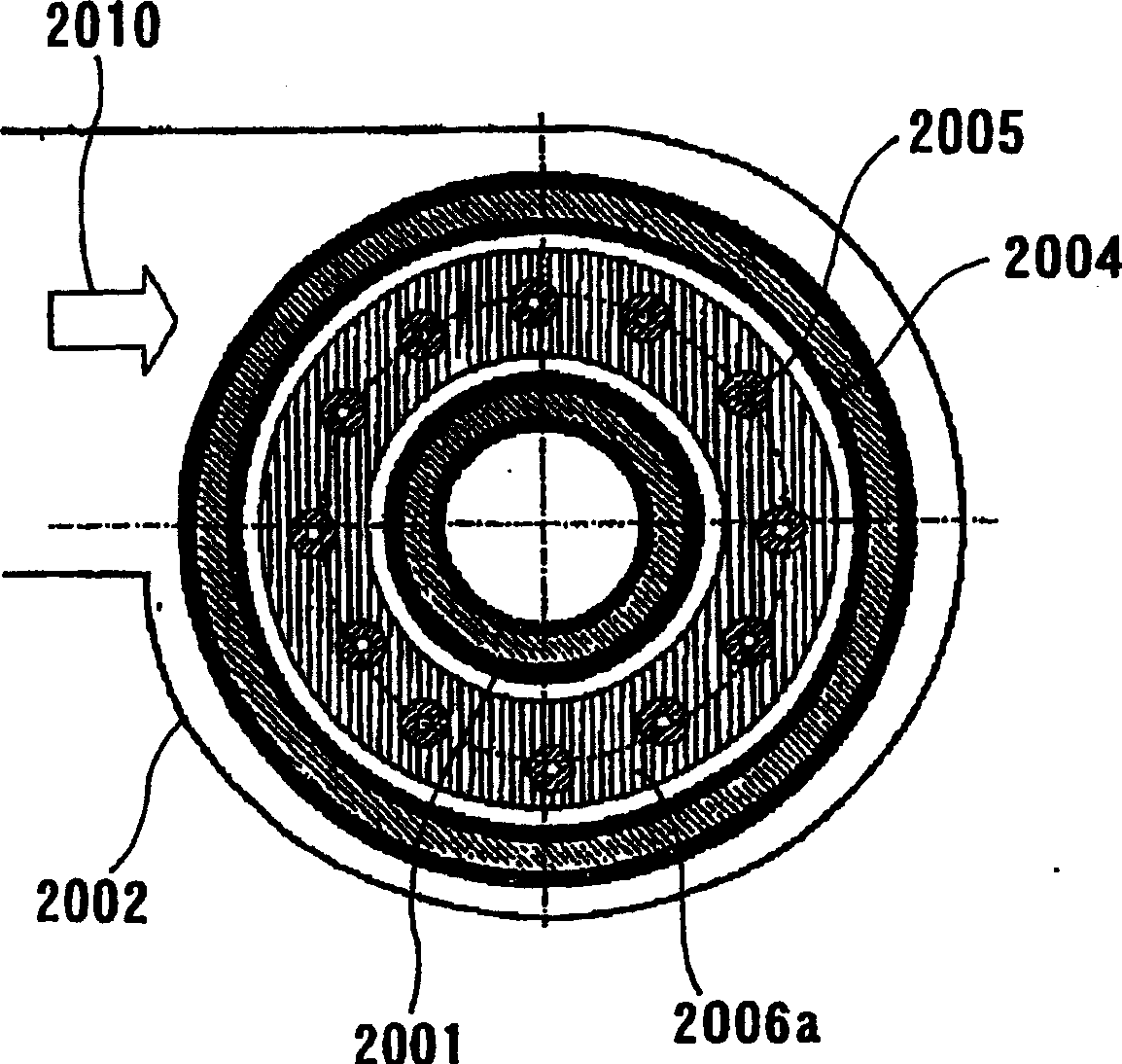

[0103] Below, refer to Figure 5 to Figure 38 , the combustion device according to the embodiment of the present invention will be described. In addition, in each embodiment, the same code|symbol is attached|subjected to the same part, and overlapping description is abbreviate|omitted.

[0104] First, refer to Figure 5 and Figure 6, the combustion device in the first embodiment will be described. Figure 5 The combustion device shown has an annular vessel 12 closed at one end (closed end) 10, an inflow housing 14, a gyrator 16 and fuel disposed on the inside at the upper end (closed end) 10 of said annular vessel 12 Nozzle 18. On the side surface of the outer periphery of the annular container 12 (outer cylinder portion 13 described later), a plurality of air inflow portions 20 are formed at the same pitch, so that combustion air 22 flows into the annular container 12 through the air inflow portions 20 . The inflow path formed by the air inflow part 20 , the inflow hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com