Multi-stage oil-less gas compressor

A screw compressor and compressor technology, which is applied in the direction of liquid variable volume machinery, mechanical equipment, variable volume pump components, etc., to achieve the effect of reducing costs and high heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

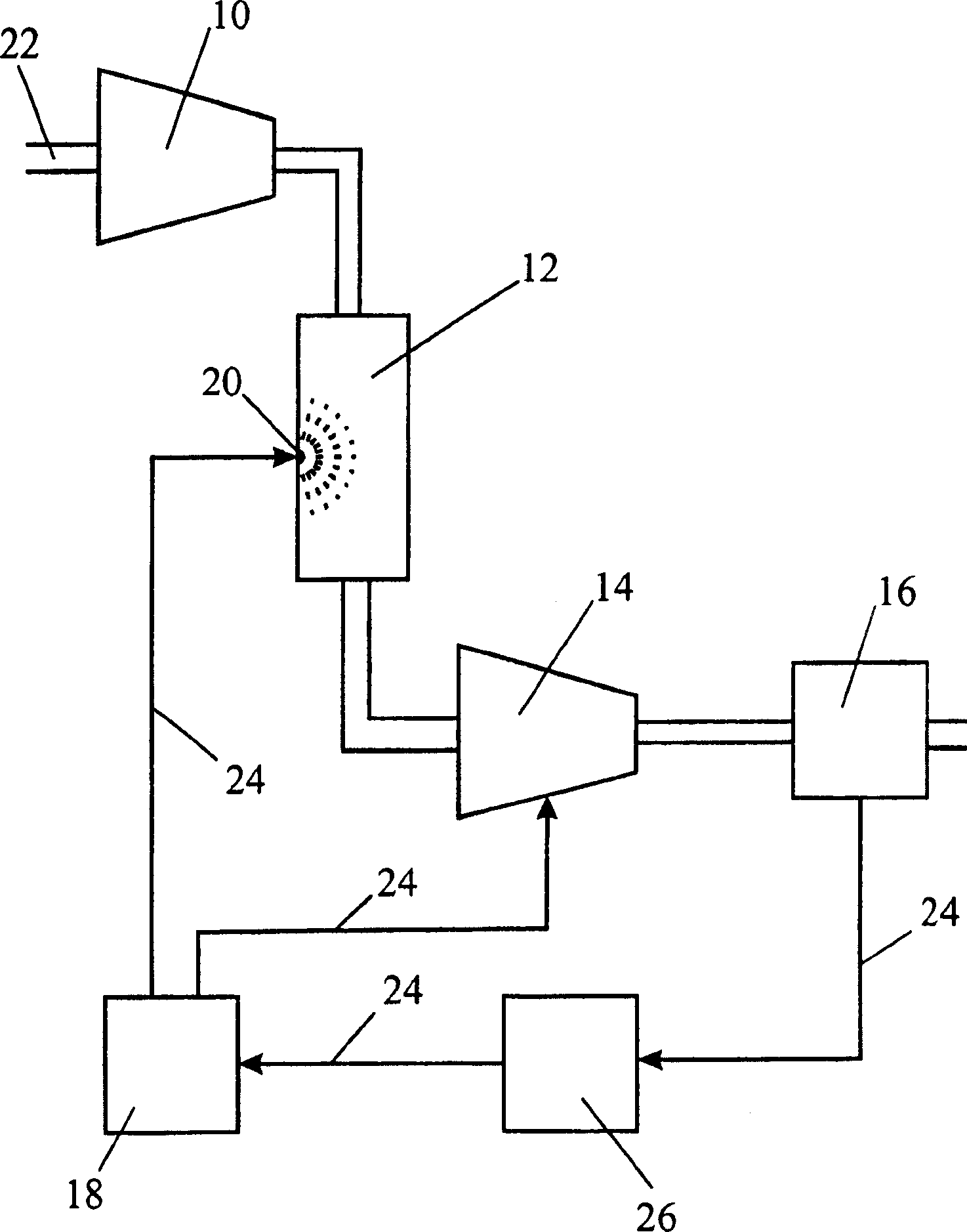

[0019] In the only figure, the ducts along which the gas flows are shown with double lines, while the pipes for carrying water, indicated at 24, are shown with one line.

[0020] The gas to be compressed enters the electrically driven centrifugal compressor 10 at 22 . Once compressed by centrifugal compressor 10 , the hot gas flows through water jet intercooler 12 .

[0021] The water jet intercooler 12 is actually a tank that slows down the gas. Simultaneously, water is sprayed into the tank through nozzles or injectors 20 at high pressure. These cause the water to be atomized into a fine mist which cools the now slowed moving gas giving the water more time to absorb heat from the gas. Adjust the water flow velocity in the intercooler and the droplet size of the jet to ensure that the heat of compression of the gas is accepted by the cooling water. This method of cooling avoids the use of heat exchangers, which are bulky, expensive, create pressure drops, and are prone to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com