Method for repairing cracks on arcwall face of metalwork

A curved surface and crack technology, applied in the field of mechanical maintenance, can solve problems such as it is difficult to ensure the effective working life of repaired quality objects, and achieve the effect of remarkable technological advancement, strong work reliability and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

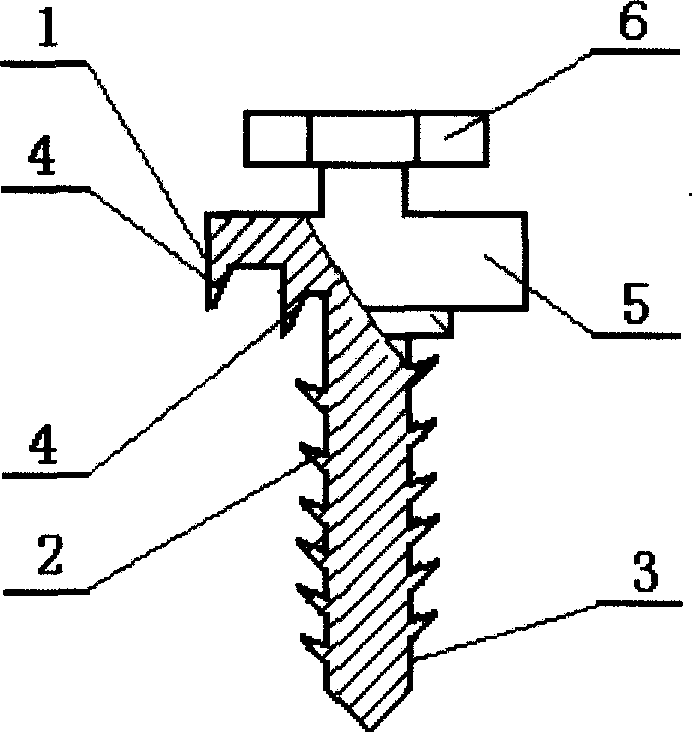

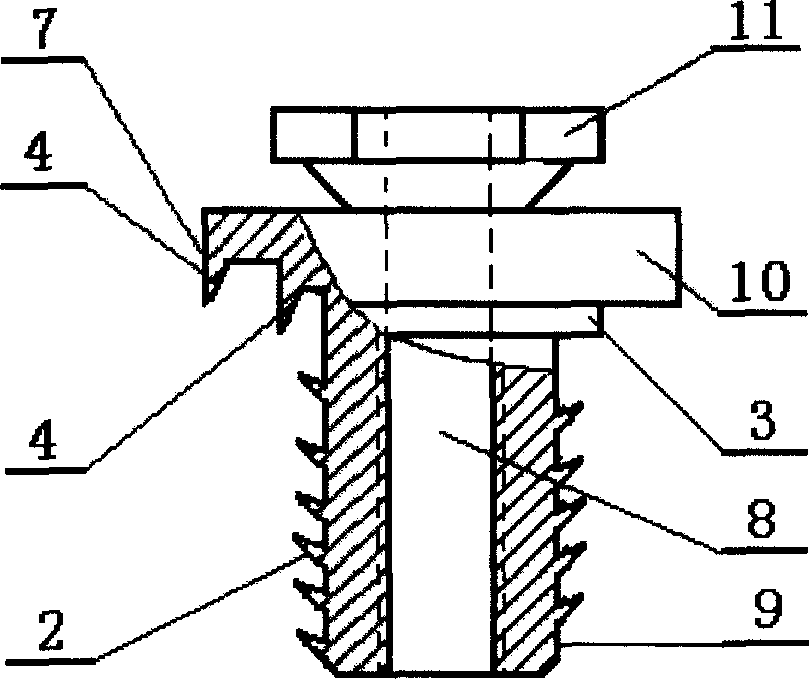

[0047] exist figure 1 , figure 2 , image 3 and Figure 4 Among them, the stitching bolt 1 used in the method for repairing the cracks on the arc surface of the metal object in the present invention consists of a bolt body 3 provided with a stop screw thread 2, a stopper shoulder 5 with stopper teeth 4 and an overrun The control screw head 6 that automatically breaks off is formed; the threaded hole 8 is provided in the center of the sewing screw sleeve 7, the screw sleeve main body 9 that is provided with a stop screw thread 2 on the periphery, the limit card shoulder 10 with the limit card teeth 4 and the super The control screw head 11 that can automatically break off is formed; the arc-shaped repair insert 12 is composed of a main part 12-1 and an auxiliary part 12-2 that match the arc, wherein the main part 12-1 is in the shape of a blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com