Needle retraction type safety injector

A safety syringe and needle technology, applied in the directions of syringes, hypodermic injection devices, infusion sets, etc., can solve the problems of inconvenient mass production, unreasonable concave-convex matching structure, and high precision, and achieve the effects of easy mass production, easy detachment, and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

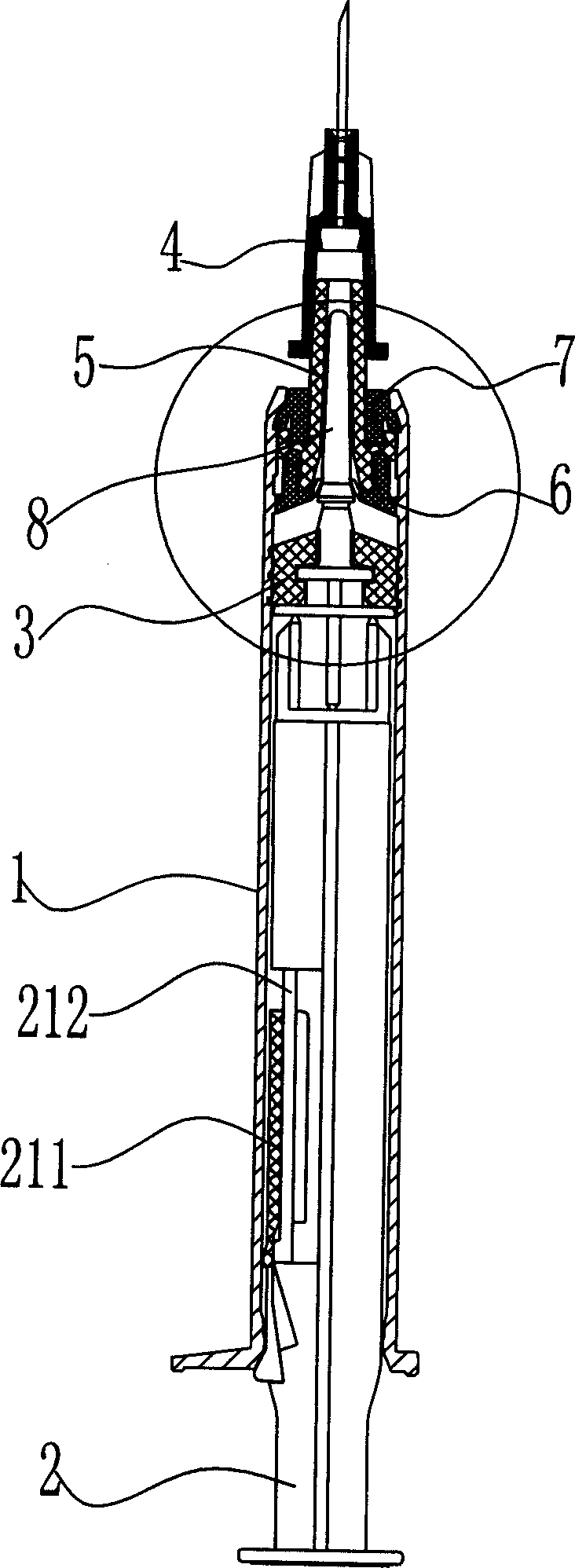

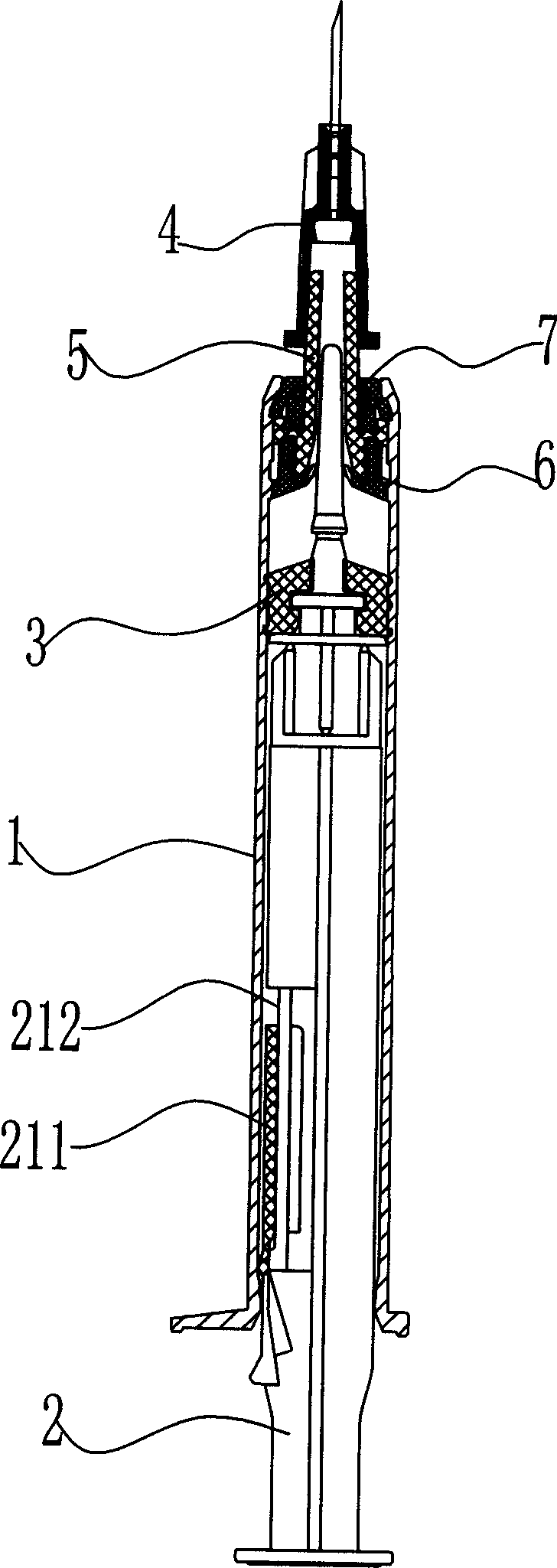

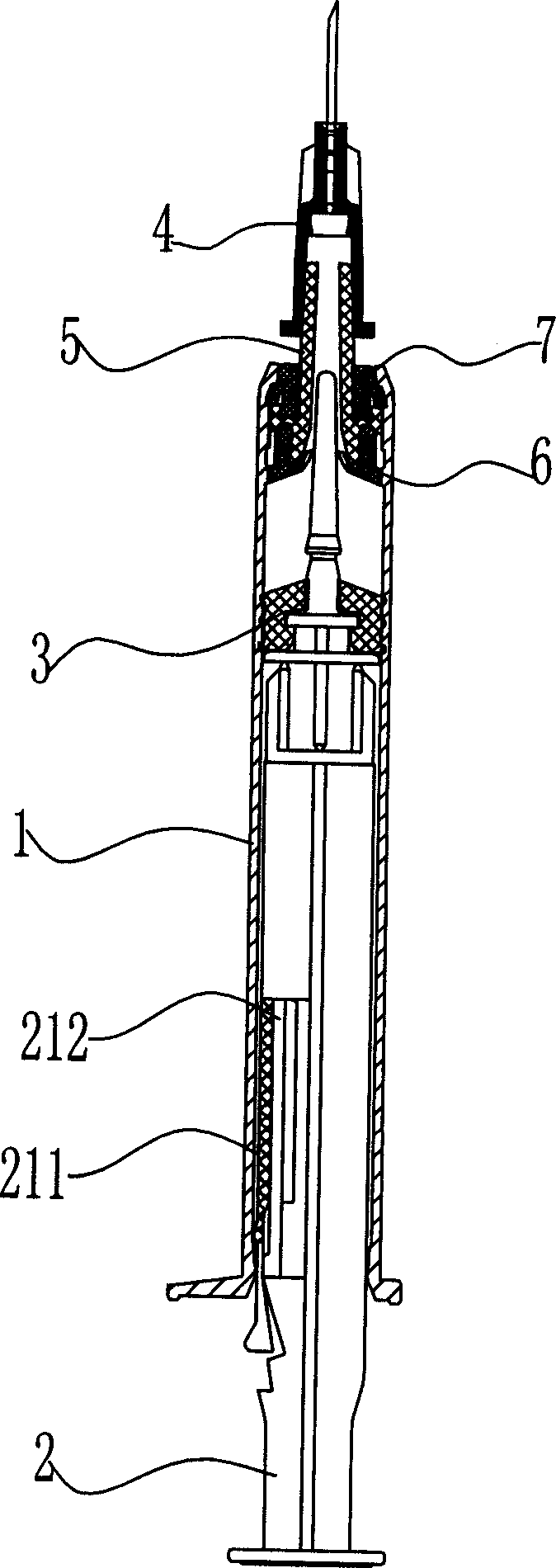

[0035] Embodiment 1: see figure 1 , Figure 9 Shown: the present invention comprises a hollow syringe 1, push rod 2, rubber plug 3, needle seat 4, elastic connection needle seat 5, support seat 6, sealing rubber plug 7, card core 8, needle seat 4 and elastic connection needle The seat 5 is connected, and the elastic connection needle seat 5 is limited by the support seat 6 on the upper end of the syringe 1,

[0036] see Figure 10 There is a circle of grooves 111 on the inner side of the upper end of the syringe 1, a circle of bosses 112 are arranged under the groove 111, an inclined convex step 113 is arranged on the inner side of the lower end of the syringe 1, and an inclined groove 114 is arranged on the inner side of the end of the syringe 1. The slot 114 and the inner wall of the syringe 1 form a slope 115 .

[0037] see Figure 11 , Figure 12 , the elastic connection needle base 5 is provided with an inner cavity 511 through which the injection liquid passes, and ...

Embodiment 2

[0045] See Figure 20, Figure 21 , Fig. 22, another structure of the elastic coupling needle base 5 is given in this embodiment, the structure of the elastic coupling needle base 5 is basically the same as the elastic coupling needle base 5 shown in Embodiment 1, the difference is that A circle 5112 is arranged on the upper end surface of the joint between the elastic support claw 512 and the supporting foot 513, and a sealing ring 5113 is arranged between the outer side of the circle 5112 and the inner wall of the syringe 1 accordingly.

[0046] Other structures in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com