Manipulator having cross-in/cross-out and retardation controller

A deceleration control and control device technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of reduced speed, large movement vibration, and difficult vibration control, etc., to achieve improved deceleration effect, good coordination accuracy, and high stop accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] With reference to accompanying drawing, the present invention will be described in detail below:

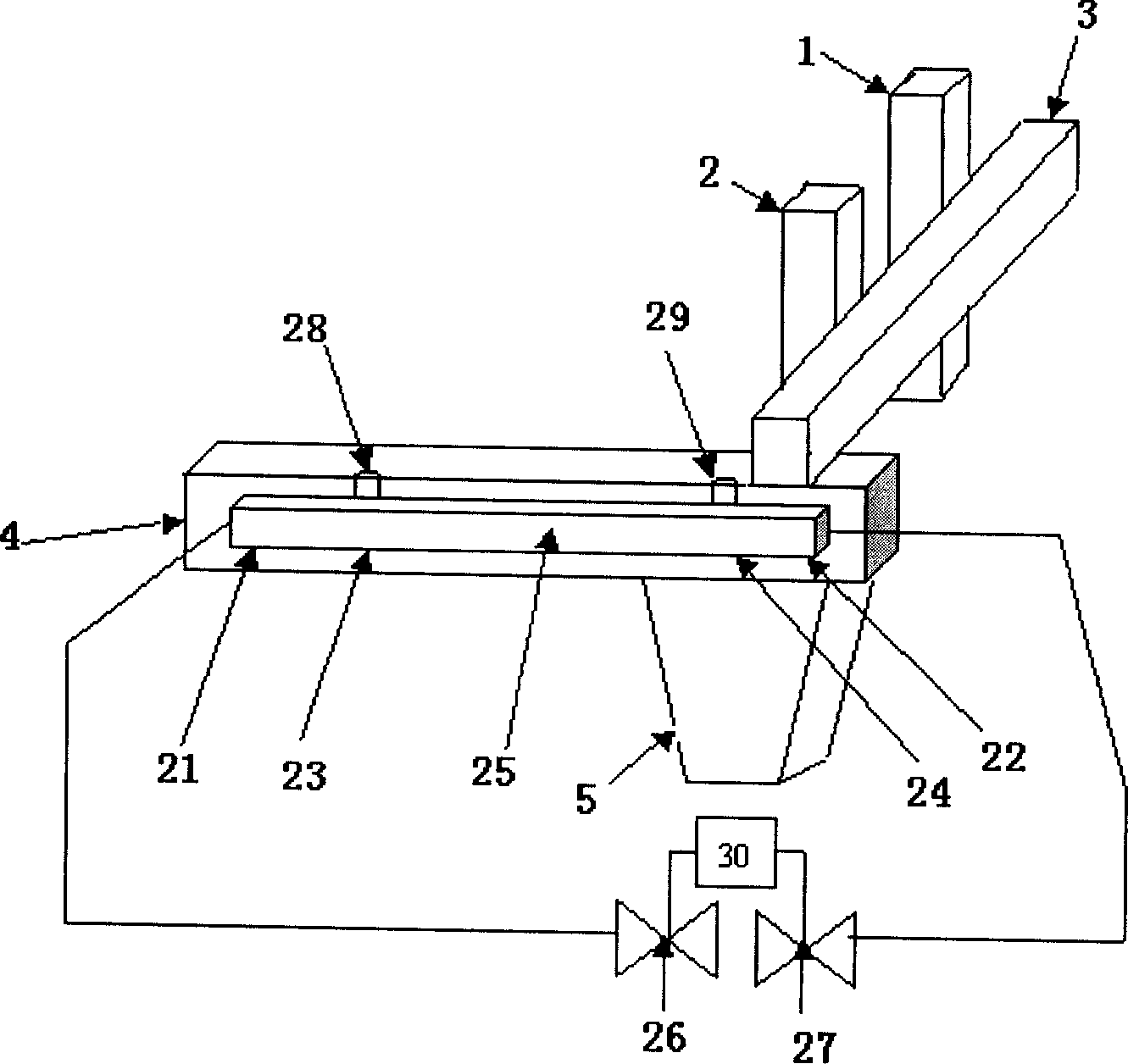

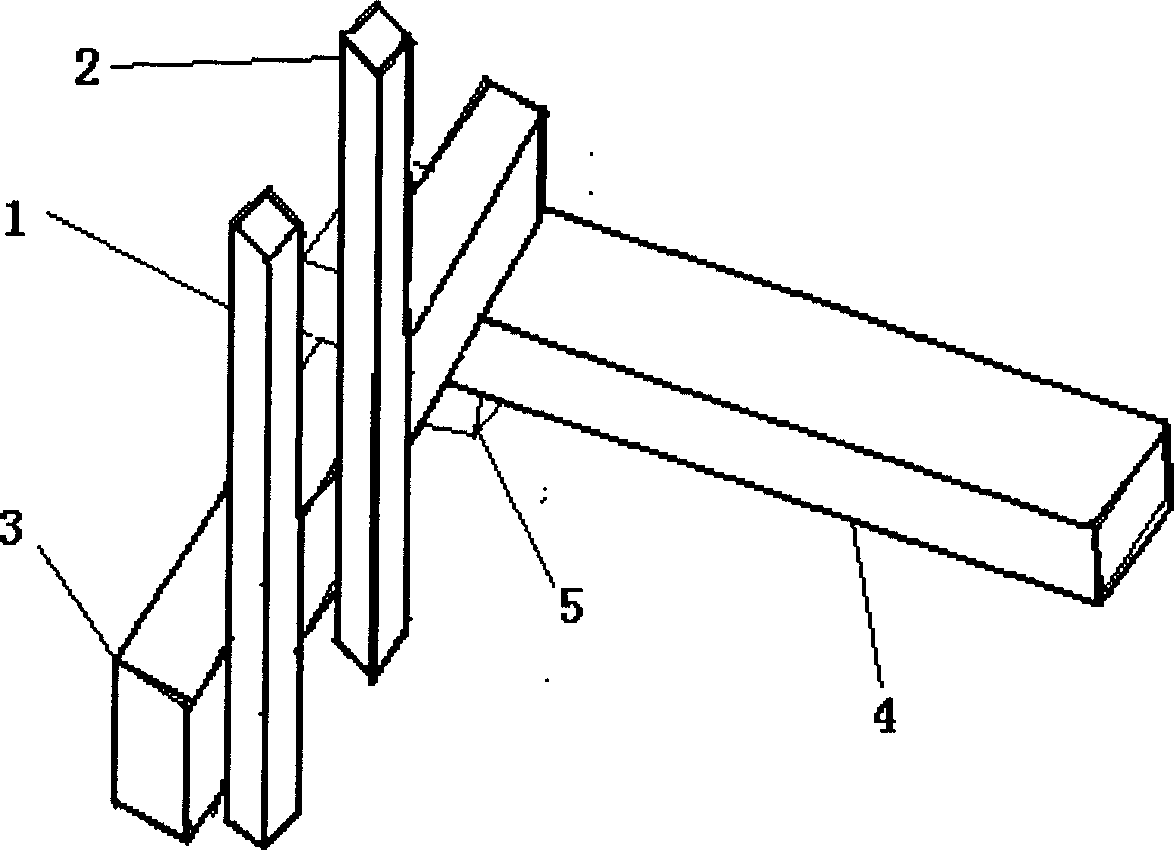

[0014] A manipulator with a cross-in and cross-out deceleration control device, with two retrieving arms, the main arm 1 and the auxiliary arm 2, the main arm 1 and the auxiliary arm 2 are installed on the drawing beam 3, and the drawing beam 3 is installed on the cross beam 4 above. The main arm 1 and the auxiliary arm 2 can move up and down, and they can also move forward and backward on the drawing beam 3. The drawing beam 3 can move in and out horizontally on the beam 4, so that the manipulator has X, Y , the degree of freedom movement in the Z direction, all movements are controlled by the air pressure solenoid valve through the cylinder 25 and driven by air pressure. The base 5 of the manipulator is installed on the injection molding machine, and the base 5 and the beam 4 are fixed together to support the whole manipulator. The cross-in and cross-out action is move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com