Gearing with error compensation for precision mechanisms

A timer and gear technology, applied to the adjustment of gear sets, gear mechanisms, components with teeth, etc., can solve problems such as static charge generation and degassing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

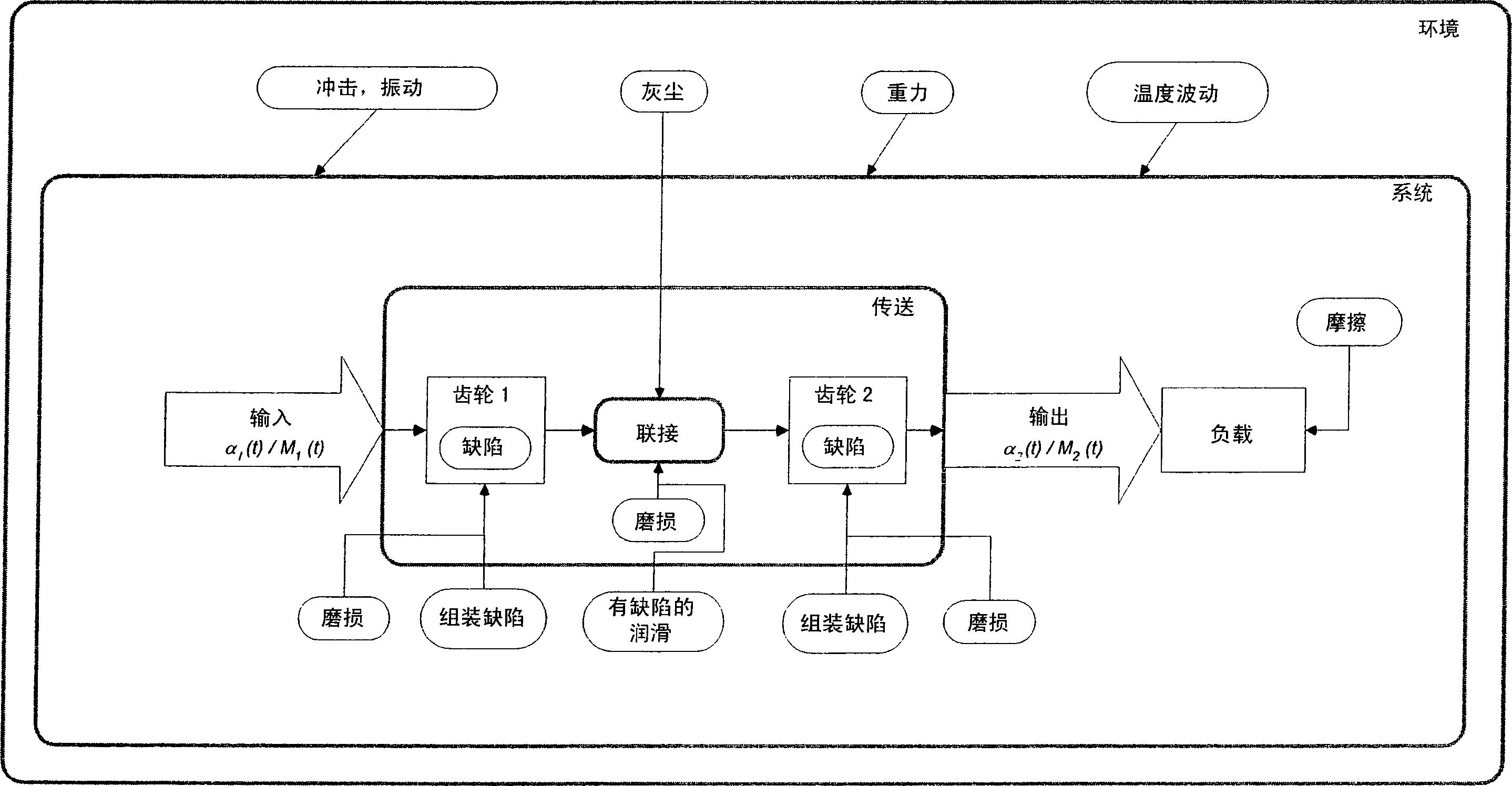

[0029] figure 1 The diagram shows the time α in the gear assembly as 1 (t) affects angular displacement transmission as a function of time ω 1 (t) affects the transmission of angular velocity and as a function of time M 1 The function of (t) affects several parameters of torque transmission. These effects come from the system itself and include imperfections of the gears, including those of their toothings. Defects particularly mentioned are roundness distortion, eccentricity, inclination of the shaft, variations in ring gear penetration due to variations in center-to-center spacing, rotational play in bearings, wear, twisted teeth and lubricant aging. These influences also originate from external factors such as shock and vibration, dust, gravity and temperature changes.

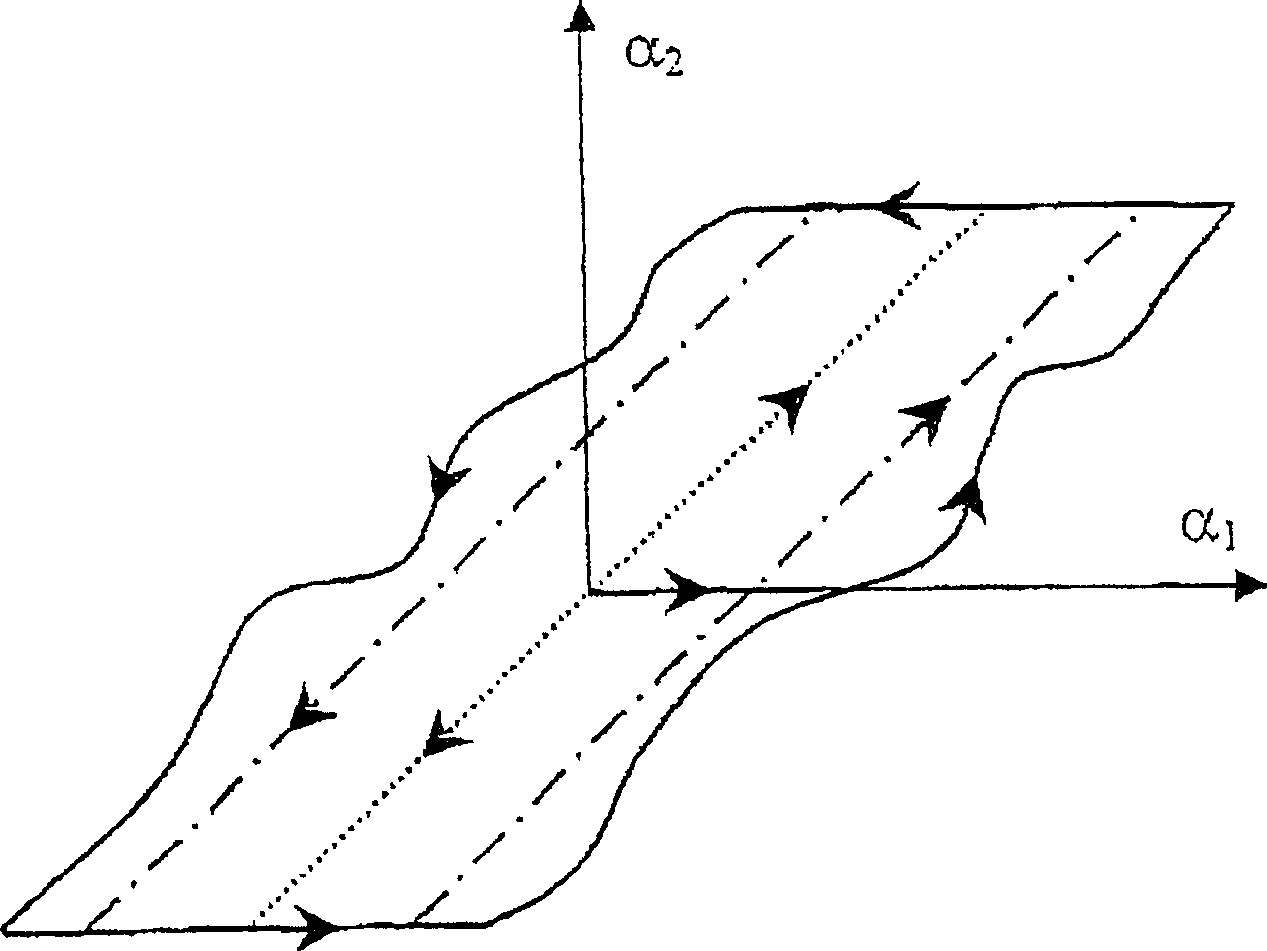

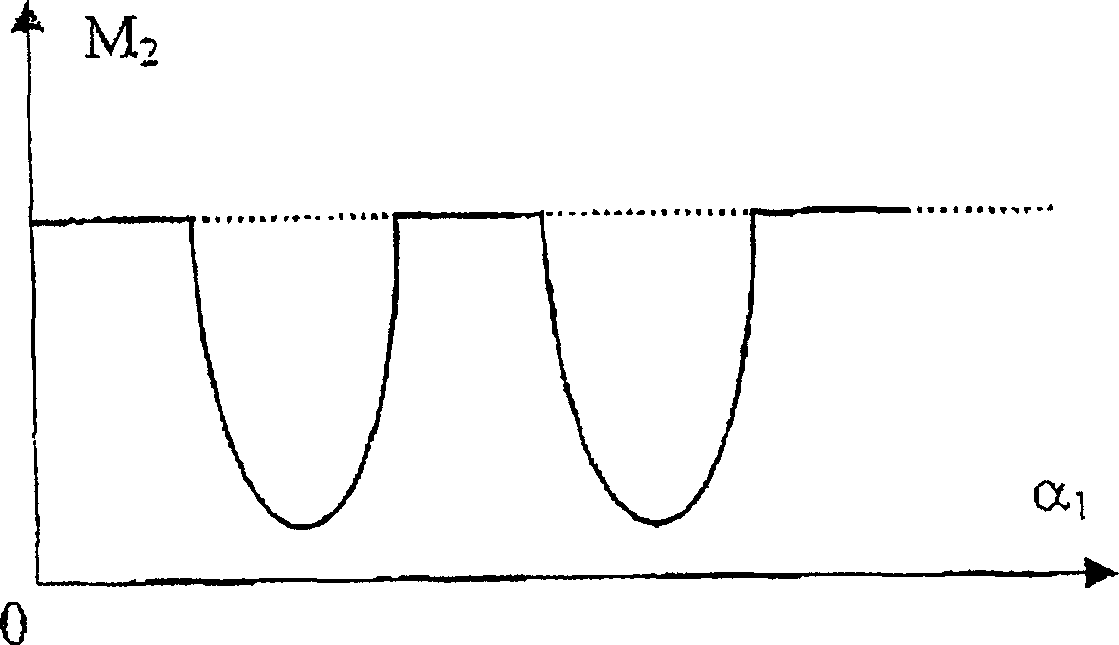

[0030] The angular displacement α relative to the driven moving part if the sum of all potential defects within accepted tolerances is considered 2 The angular displacement of the driving moving part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com