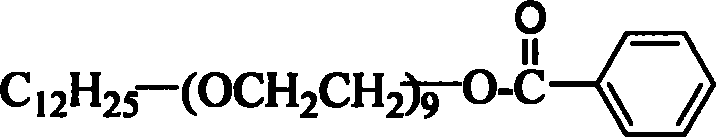

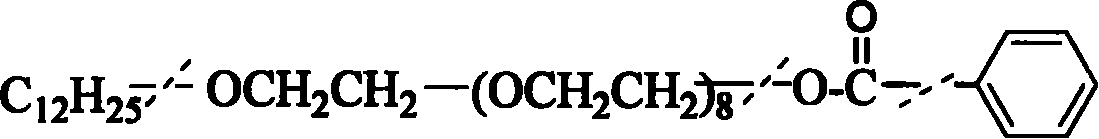

Lauryl alcohol polyethylene glycol oxide ester benzoic ether and its synthesis

A technology of lauryl alcohol polyoxyethylene ether and benzoate, which is applied in the field of alcohol-based nonionic surfactants and lauryl alcohol polyoxyethylene ether benzoate surfactants, can solve environmental hazards, waste of resources and energy And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

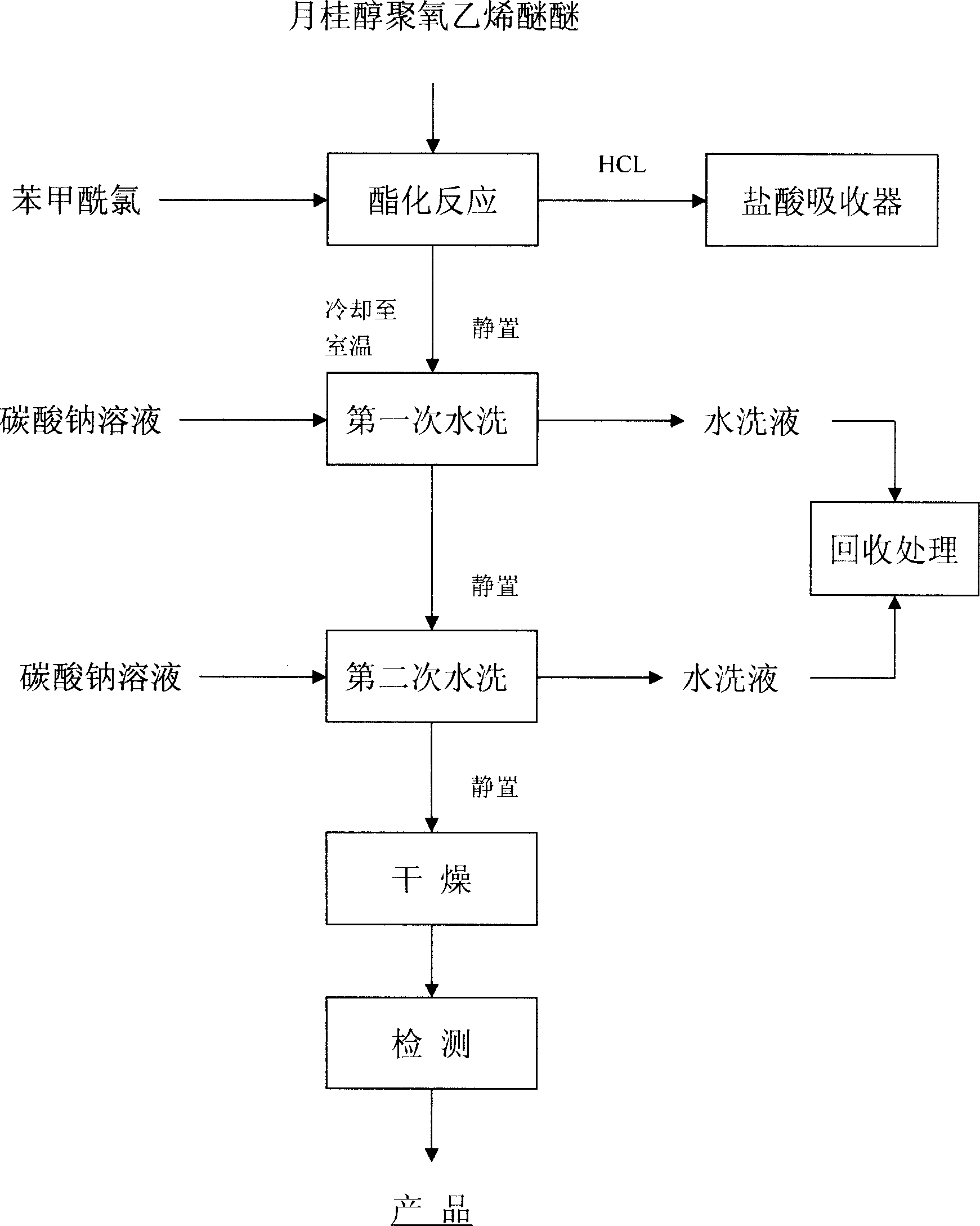

Method used

Image

Examples

Embodiment 1

[0033] Put the measured 1mmol lauryl polyoxyethylene ether (n=9) into a 50ml round bottom flask, then place the flask in an oil bath heater to heat, and add the measured 1.00mmol benzoyl chloride to the constant pressure drop In the funnel, when the temperature in the flask rises to 55-60°C, stop heating, turn on the agitator, and slowly add benzoyl chloride dropwise; after the dropwise addition, raise the heating temperature to 85-90°C, and react for 3-4 hours , stop stirring, let stand.

Embodiment 2

[0035] Put the metered 1mmol of polyoxyethylene lauryl ether (n=9) into a 50ml round bottom flask, then place the flask in an oil bath heater to heat, and add the metered 1.05mmol of benzoyl chloride to the constant pressure drop In the funnel, when the temperature in the flask rises to 55-60°C, stop heating, turn on the agitator, and slowly add benzoyl chloride dropwise; after the dropwise addition, raise the heating temperature to 85-90°C, and react for 3-4 hours , stop stirring, let stand.

Embodiment 3

[0037] Put the metered 1mmol lauryl polyoxyethylene ether (n=9) into a 50ml round bottom flask, then place the flask in an oil bath heater to heat, and add the metered 1.20mmol benzoyl chloride to the constant pressure drop In the funnel, when the temperature in the flask rises to 55-60°C, stop heating, start the agitator and slowly add benzoyl chloride dropwise; after the dropwise addition, raise the heating temperature to 85-90°C, and react for 3-4 hours. Stop stirring and let stand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com