Two-stage screw compressor

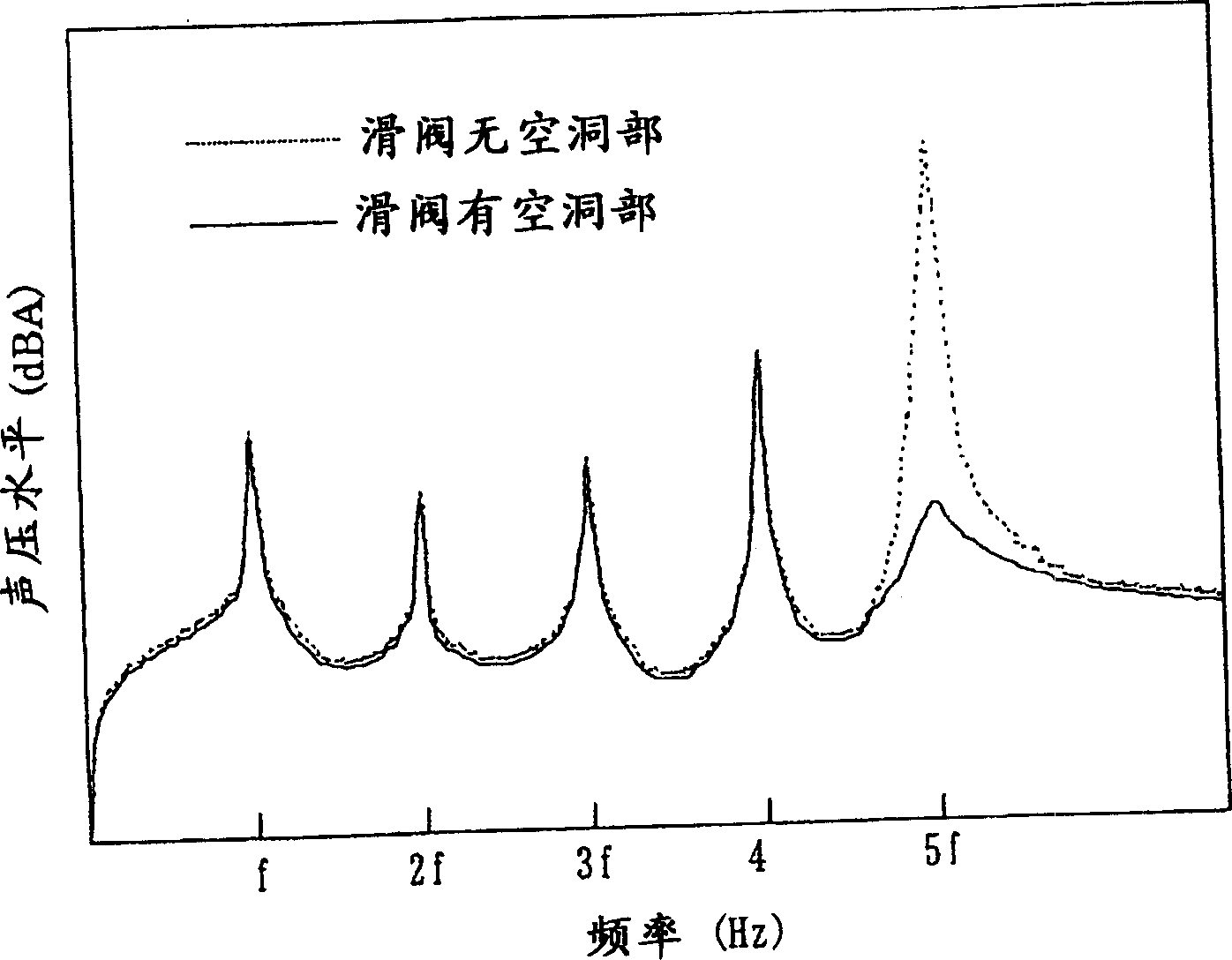

A screw compressor and compression mechanism technology, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve the problems of increasing the weight of the casting, not considering the increase of noise, and the complexity of the shape of the casting, etc., to achieve a simple structure , Prevention of internal resonance, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described below with reference to the drawings.

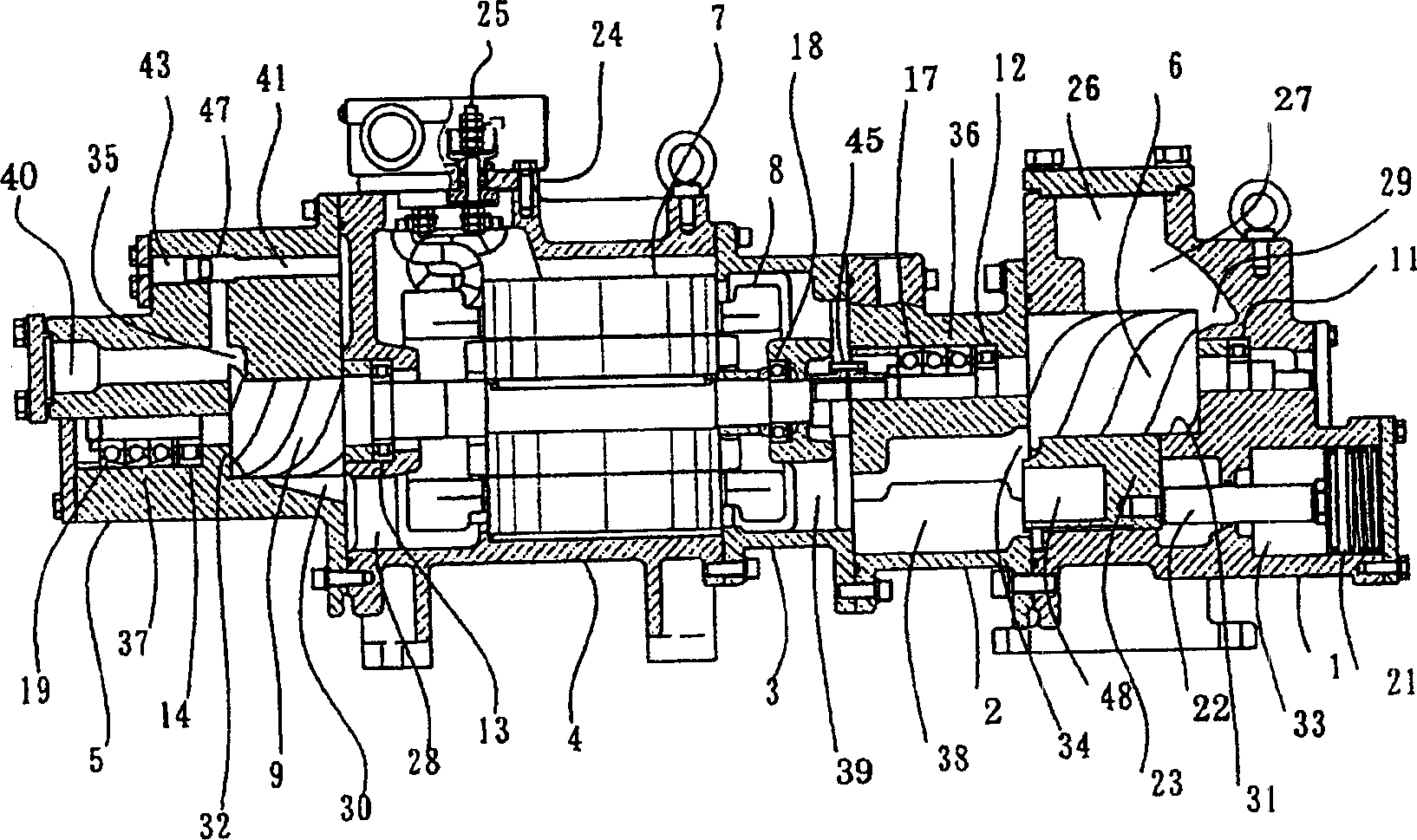

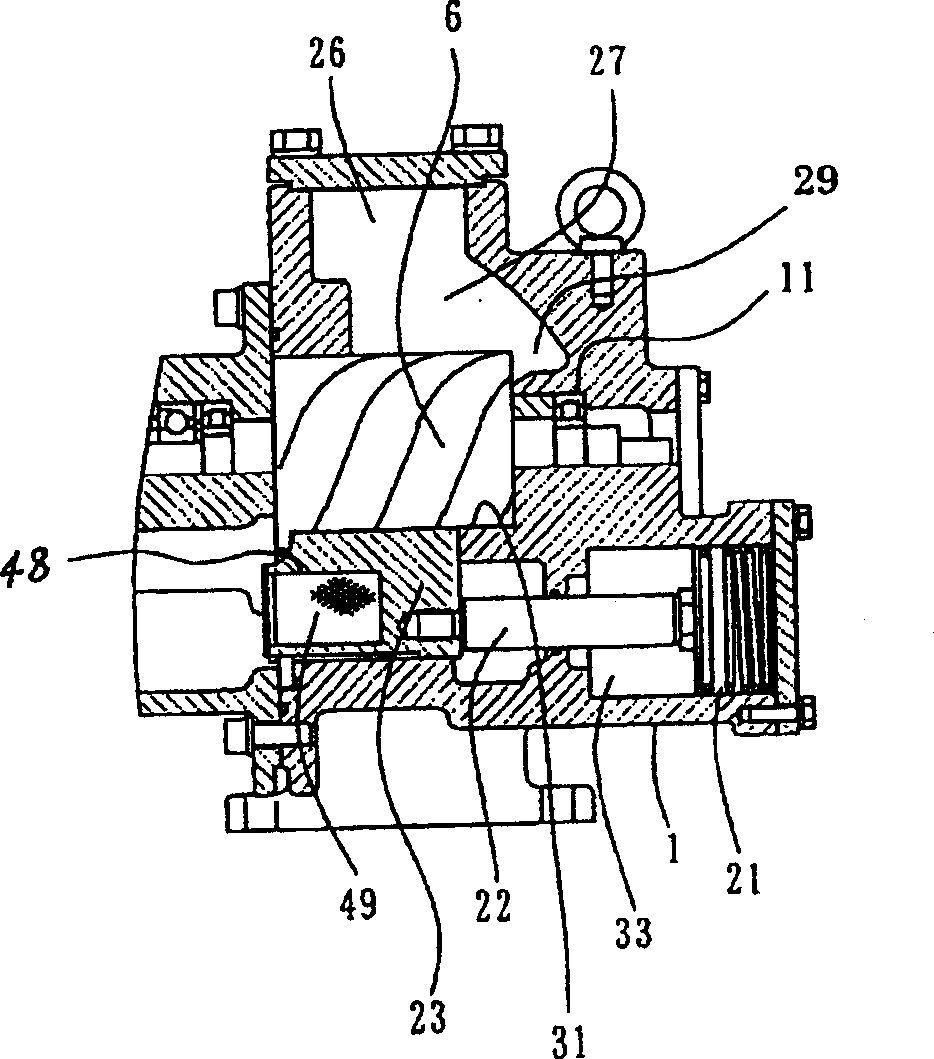

[0016] figure 1 An example of the two-stage screw compressor of the present invention is shown. The screw compressor has: a low-pressure stage casing 1 provided with a suction port 26; a discharge casing 2 connected to the discharge side of the low-pressure stage casing 1 and having a gas passage 38; a motor cover (intermediate stage casing) 3 connected to the discharge side. The downstream side of the casing 2 also has a gas passage 39 and accommodates the coil end 8 of the electric motor 7 ; the motor casing (intermediate stage casing) 4 containing the electric motor 7 ; These components are integrated by bolts or the like.

[0017] In the low-pressure stage casing 1, a cylindrical chamber 31, a suction hole 29 for introducing refrigerant gas into the cylindrical chamber 31, a piston chamber 33 for accommodating a piston 21 for driving the spool valve 23, and the like are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com