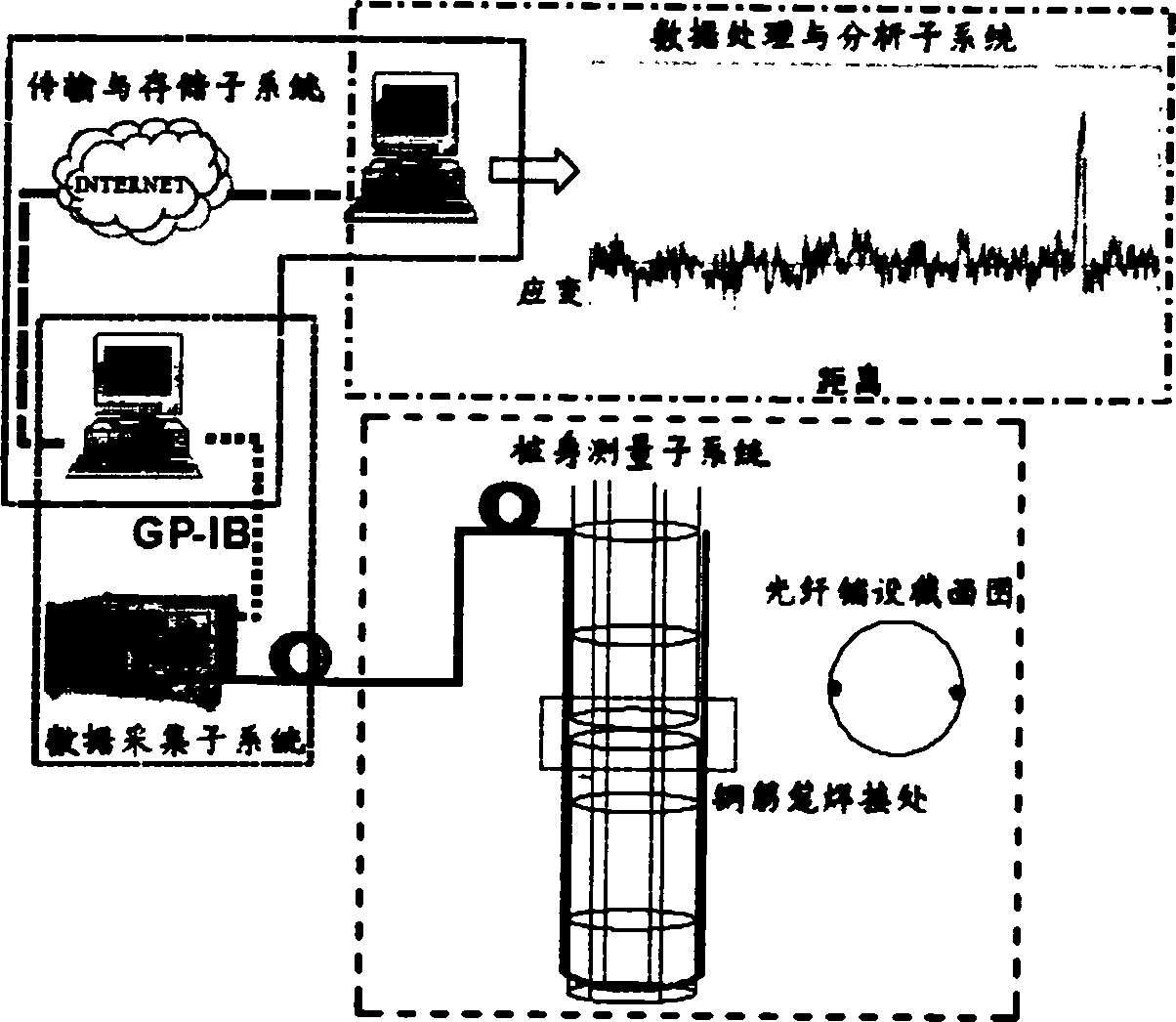

Bored concrete pile foundation distributing optical fiber sensing detecting method and system

A technology of distributed optical fiber and detection method, which is applied in the direction of using optical devices to transmit sensing components, infrastructure engineering, foundation structure tests, etc., can solve the problem of failure to reflect pile body defects and stress concentration conditions, difficult bearing capacity and pile Integrity of the body, difficulty in installing distributed optical fibers, etc., to avoid low survival rate, save detection costs, and improve monitoring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

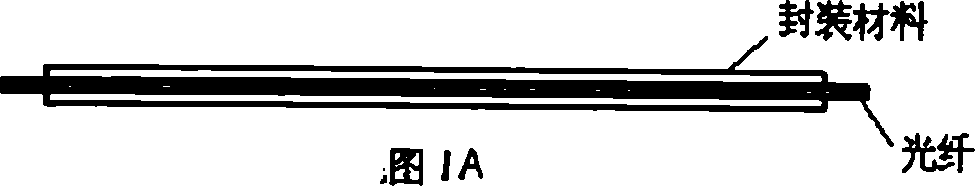

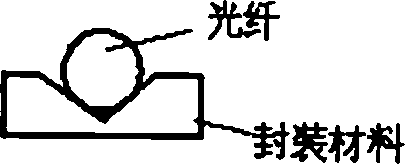

[0031] (1) Optical fiber packaging

[0032] Place the optical fiber and the carrier according to the length of the pile to be tested. The length of each fiber should be twice the length of the pile plus 5m. Spread the grooved carrier on the workbench, inject glue into the groove, then press into the single-mode nylon optical fiber to smooth it out, and use blowing to speed up the drying. After the glue is completely dry, wrap the optical fiber with a reel. During the winding process, carefully check whether there is any unglued part of the optical fiber, and reapply it in time.

[0033] (2) On-site laying

[0034] There are currently two main methods of optical fiber laying: one is to paste the optical fiber on the structure under test with a special or special adhesive, which is mainly used for the monitoring of built structures; the other is to implant the optical fiber In structures such as reinforced concrete, this method is mainly used for safety and quality monitoring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com